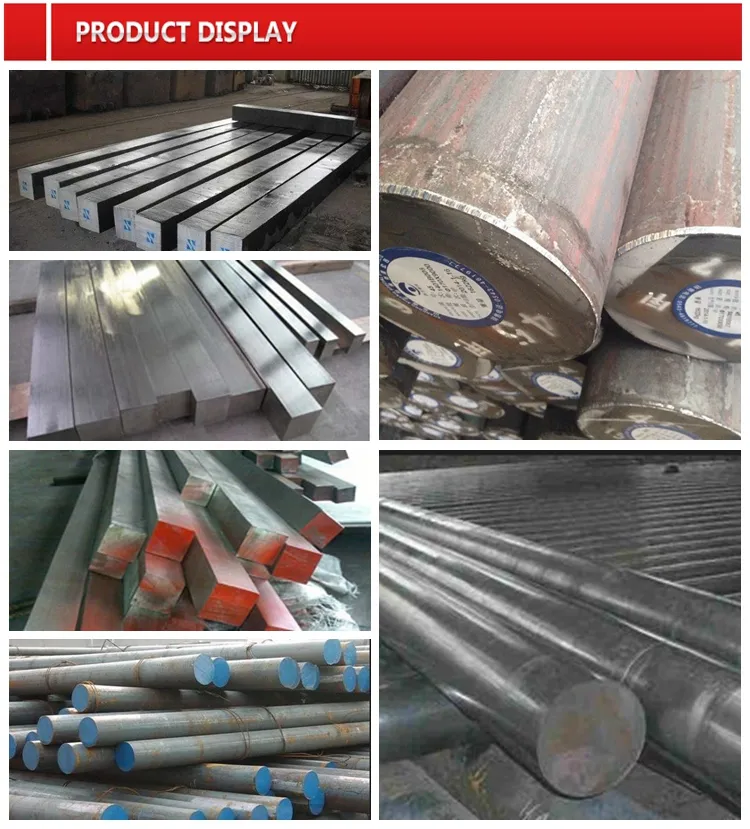

AISI H11/DIN 1.2343/JIS SKD6 Tool Steel Bar

AISI H11 /DIN 1.2343 /JIS SKD6 tool steel bar1.Supply Form & Size & ToleranceSupply FormSize(mm)ProcessToleranceRoundΦ6-Φ100Cold DrawnBright/BlackBest H11Φ16-Φ350Hot RolledBlack-0/+1mmPeeled/groundBest H11Φ90-Φ1000Hot ForgedBlack-0/+5mmRough Tu......

Send Inquiry

Product Description

AISI H11 /DIN 1.2343 /JIS SKD6 tool steel bar

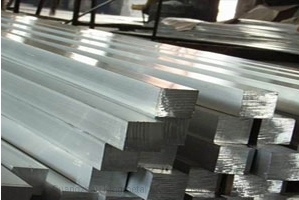

1.Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

2.Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Cr | V | Mo |

| ASTM A681 | H11 | 0.35-0.45 | 0.8-1.25 | 0.2-0.6 | 0.03 | 0.03 | 4.75-5.5 | 0.3-0.6 | 1.1-1.6 |

| DIN ISO 4957 | 1.2343 | 0.28-0.35 | 0.8-1.2 | 0.1-0.4 | 0.03 | 0.03 | 2.7-3.2 | 0.4-0.7 | 1.1-1.5 |

| JIS G4404 | SKD6 | 0.32-0.42 | 0.8-1.2 | 0.5 | 0.03 | 0.03 | 4.5-5.5 | 0.3-0.5 | 1.0-1.5 |

| BS 4659 | BH11 | 0.32-0.40 | 0.85-1.15 | 0.4 | 0.35 | 0.35 | 4.75-5.25 | 0.3-0.5 | 1.25-1.75 |

3.Physical Property

| Temperature | 20°C | 200°C | 400°C | 600°C |

| Density,kg/m3 | 7800 | 7750 | 7700 | 7600 |

| Modulus of elasticity,Mpa | 210000 | 200000 | 180000 | 140000 |

| Coefficient of thermal expansion from 20°C,per °C | - | 11.6 x 10^-6 | 12.4 x 10^-6 | 13.2 x 10^-6 |

| Thermal conductivity,W/m °C | - | 30 | 30 | 31 |

4. Mechanical Property

| Hardness,HRC | 45 | 46.5 | 48.5 |

| Tensile strength,Mpa | 1450 | 1580 | 1680 |

| Yield strength Rp 0.2,Mpa | 1240 | 1340 | 1410 |

| Elongation A5 ,% | 13 | 13 | 12 |

| Reduction in area Z,% | 65 | 65 | 64 |

5.Forging

H11 tool steels are forged at 900- 1120°C .Reheat is necessary when temperature below 900°C ,AISI H11 steel should be cooled as slowly as possible in the furnace,annealing is recommended after forged.

6.Stress Relieving

Stress relieving to remove machining stresses should be carried out by heat to 650°C, holding for one hour at heat, cooling in the furnace. This operation is performed to reduce distortion during heat treatment.

7.Annealing

Heating slowly and uniformly to 845~900ºC, furnace cooling to 540ºC at a rate 10~20ºC per hour, obtain hardness HB 229 max.

8.Hardening

Harden from a temperature of 1000-1040ºC followed by air, oil quenching or warm bath quenching 500-550ºC

C. Hardness after quenching is 50-56 HRC.

9.Tempering

Temper at 540°C to 650°C for Rockwell C hardness of 54 to 38.Temper minimum twice with intermediate cooling to room temperature. Holding time at temperature is minimum 2 hours.

| Tempering,ºC | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 53 | 52 | 52 | 52 | 54 | 52 | 48 | 38 | 30 |

| Rm,N/mm2 | 1845 | 1790 | 1790 | 1790 | 1910 | 1790 | 1570 | 1200 | 970 |

10.Application

AISI H11 is widely usd for highly stressed hot work tools,typical use are:

1.Extrusion Industry: Dies and Contatiner for Extrusion

2.Forging Industry: Forming Dies, Press Dies

3.Die Casting Industry: Dies for Die-Carbide

4.Aircraft Industry: Landing Gears, Arrester Hooks