Why Stainless Steel Heat Exchanger Pipe Matters for Efficient Thermal Systems?

2025-12-25

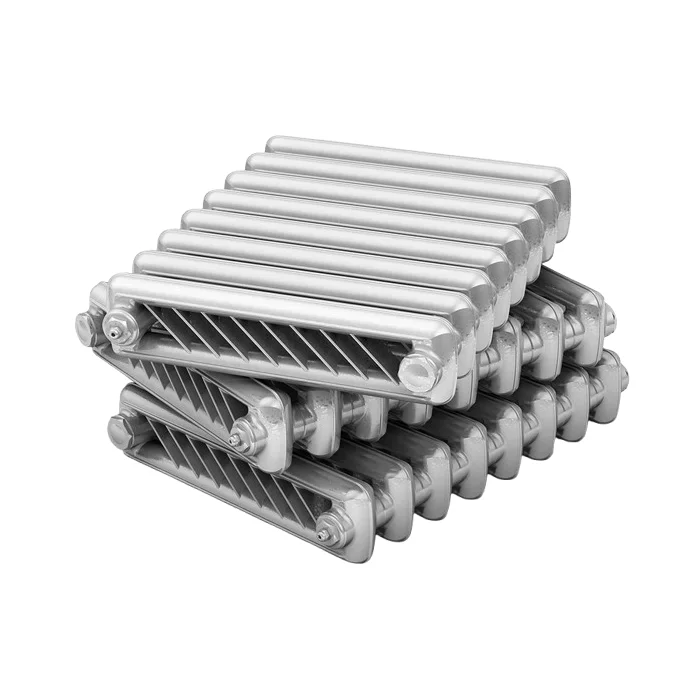

In modern industrial production and energy systems, heat transfer efficiency directly determines operating cost, safety, and long-term reliability. From petrochemical plants and power generation to food processing and HVAC systems, the choice of heat exchanger components plays a critical role. Among them, Stainless Steel Heat Exchanger Pipe has become a preferred solution due to its excellent balance of strength, corrosion resistance, and thermal performance. As an experienced manufacturer, Zhejiang Shuangsen Metal Technology Co., Ltd. focuses on delivering high-quality stainless steel pipes that help customers achieve stable, efficient, and cost-effective heat exchange systems worldwide.

What Is a Stainless Steel Heat Exchanger Pipe?

A Stainless Steel Heat Exchanger Pipe is a specially designed tube used to transfer heat between fluids in heat exchangers such as shell-and-tube, plate, or condenser systems. These pipes are typically made from grades like 304, 316L, 321, or duplex stainless steel to withstand high temperatures, pressure, and corrosive environments.

Key Characteristics

-

High thermal conductivity for efficient heat transfer

-

Excellent corrosion and oxidation resistance

-

Smooth inner surface to reduce fouling

-

Long service life with low maintenance requirements

How Does a Stainless Steel Heat Exchanger Pipe Work?

The working principle is simple but highly effective. Fluids at different temperatures flow on opposite sides of the pipe wall. Heat is transferred through the stainless steel pipe material without direct contact between fluids, ensuring safety and efficiency. The stable metallurgical structure of stainless steel ensures consistent performance even under fluctuating pressure and temperature conditions.

Why Is Stainless Steel Heat Exchanger Pipe Important?

The importance of Stainless Steel Heat Exchanger Pipe lies in its ability to maintain performance over time while reducing operational risks.

Importance Highlights

-

Prevents leakage and contamination

-

Supports high-pressure and high-temperature operations

-

Meets strict hygiene standards in food and pharmaceutical industries

-

Reduces downtime and replacement frequency

For industries seeking long-term reliability, stainless steel pipes are not just components—they are strategic investments.

What Are the Main Functions and Effects?

Core Functions

-

Efficient heat transfer

-

Structural support under pressure

-

Corrosion protection in aggressive media

Practical Effects in Use

-

Improved energy efficiency

-

Stable system operation

-

Lower lifecycle cost

-

Enhanced safety compliance

Stainless Steel vs Carbon Steel Heat Exchanger Pipe

| Feature | Stainless Steel Heat Exchanger Pipe | Carbon Steel Pipe |

|---|---|---|

| Corrosion Resistance | Excellent | Limited |

| Service Life | Long | Shorter |

| Maintenance Cost | Low | Higher |

| Application Range | Wide, harsh environments | Mild conditions |

This comparison clearly shows why stainless steel is widely chosen for demanding industrial applications.

Which Industries Use Stainless Steel Heat Exchanger Pipe?

Stainless Steel Heat Exchanger Pipe is widely used in:

-

Oil & Gas and Petrochemical

-

Power plants and energy systems

-

Chemical processing

-

Food & Beverage production

-

Pharmaceutical and medical equipment

-

HVAC and refrigeration

Zhejiang Shuangsen Metal Technology Co., Ltd. provides customized solutions tailored to these industries, ensuring compliance with international standards and customer-specific requirements.

Why Choose Zhejiang Shuangsen Metal Technology Co., Ltd.?

With advanced production equipment, strict quality control, and years of export experience, Zhejiang Shuangsen Metal Technology Co., Ltd. delivers stainless steel heat exchanger pipes with:

-

Precise dimensional tolerance

-

Consistent material performance

-

International certifications

-

Reliable delivery and technical support

Our products are designed to help clients improve system efficiency while strengthening their competitive advantage.

Final Thoughts

Choosing the right Stainless Steel Heat Exchanger Pipe directly impacts efficiency, safety, and long-term profitability. With its superior performance and adaptability, stainless steel remains the optimal material for modern heat exchange systems. If you are looking for a reliable supplier with both technical expertise and strong manufacturing capability, Zhejiang Shuangsen Metal Technology Co., Ltd. is ready to support your projects—contact us today to discuss your requirements and get a professional solution tailored to your needs.