Why Precision Mold is the Key to Superior Injection Molding?

2025-11-05

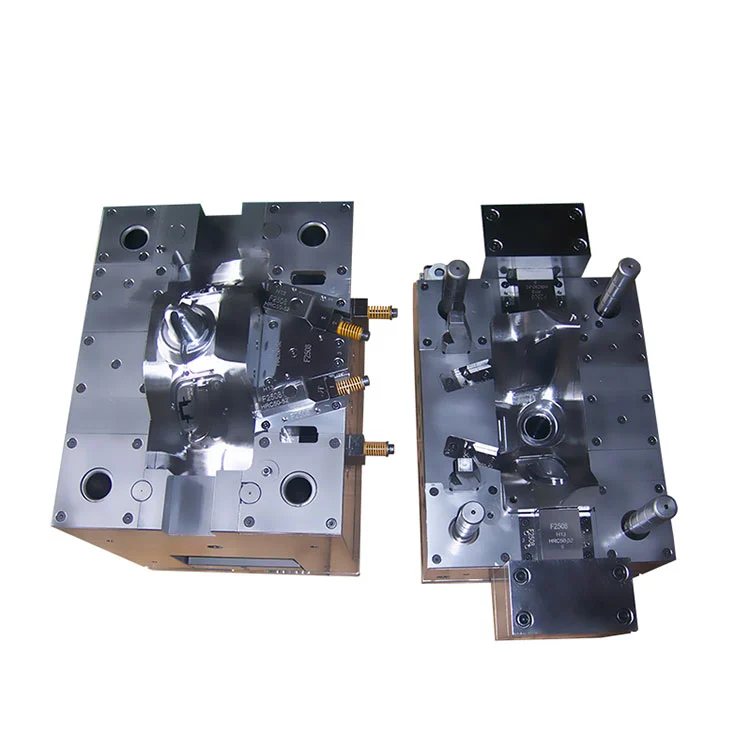

As a leading expert in the injection molding industry, I firmly believe that Precision Mold is the cornerstone of manufacturing excellence. At our company, we understand that the quality of the final product heavily relies on the precision and durability of the mold used. In this article, I will share my insights on the role, effectiveness, and importance of Precision Mold, and why it should be your top priority.

The Role of Precision Mold

Precision Mold plays a critical role in the injection molding process by ensuring that each component is produced with exact specifications. It allows for the creation of complex geometries, tight tolerances, and high-quality surface finishes. In my experience, using a high-quality Precision Mold minimizes defects and reduces waste, ultimately saving time and resources. Our team at Ningbo Moldor Plastic Co., Ltd. relies on advanced Precision Mold technology to deliver consistent and reliable results for our clients.

The Impact and Benefits

The use of Precision Mold leads to remarkable outcomes in production. Here are some key benefits we've observed:

-

Enhanced Product Quality: Every part produced meets stringent standards, ensuring durability and functionality

-

Increased Efficiency: Precision Mold reduces cycle times and minimizes downtime, boosting overall productivity

-

Cost-Effectiveness: By lowering rejection rates and material waste, it translates into significant savings for our customers

In my own work, I've seen how investing in a superior Precision Mold can transform a project from mediocre to exceptional. It's not just about making parts—it's about crafting solutions that drive success.

Comparison of Mold Types

| Feature | Standard Mold | Precision Mold |

|---|---|---|

| Tolerance | ±0.1 mm | ±0.01 mm or better |

| Surface Finish | Good | Excellent |

| Production Speed | Standard | 20-30% Faster |

| Defect Rate | 3-5% | Less than 1% |

| Mold Life | 500,000 shots | 1,000,000+ shots |

| Cost Efficiency | Moderate | High long-term value |

| Complex Designs | Limited | Excellent capability |

The Importance of Precision Mold

Why is Precision Mold so vital? It directly impacts the scalability and reproducibility of manufacturing processes. Without it, achieving consistency across large production runs would be nearly impossible. At our facility, we emphasize that a well-designed Precision Mold is the backbone of innovation, enabling us to tackle challenging projects with confidence. My commitment to excellence drives me to advocate for the adoption of high-standard Precision Mold in every injection molding endeavor.

Frequently Asked Questions (FAQ)

Q: How does Precision Mold improve product accuracy?

A: Precision Mold is engineered with tight tolerances and advanced materials, ensuring that each injection cycle produces identical parts with minimal deviation. This level of control is essential for industries like automotive and medical devices, where precision is non-negotiable.

Q: What makes Precision Mold a cost-effective choice?

A: Although the initial investment might be higher, Precision Mold reduces long-term costs by minimizing rework, scrap, and maintenance. In my projects, I've found that it pays for itself through improved efficiency and fewer production interruptions.

Q: Can Precision Mold handle complex designs?

A: Absolutely! With modern technology, Precision Mold can accommodate intricate shapes and fine details. Our team at Ningbo Moldor Plastic Co., Ltd. has successfully executed numerous complex projects using customized Precision Mold solutions.

Why Choose Us?

At Ningbo Moldor Plastic Co., Ltd., we pride ourselves on delivering top-tier Precision Mold services that exceed expectations. Our dedication to quality and innovation ensures that your projects are in safe hands. Don't settle for less—embrace the power of Precision Mold to elevate your manufacturing process.

For more information or to discuss your needs, feel free to contact us. Let's create something amazing together!