Why Is Oxygen Free Copper Strip the Best Choice for Precision Conductivity Applications?

2025-07-14

What makes oxygen free copper strip superior to standard copper materials?

After more than 15 years in the electronics manufacturing field, I’ve worked with various types of conductive materials. None compare to oxygen free copper strip when it comes to electrical performance. Its purity—typically over 99.99%—and lack of oxygen content ensure unmatched conductivity, making it the go-to material for precision instruments and high-end electronic components.

How does oxygen free copper strip improve product performance?

In my experience, oxygen free copper strip significantly reduces resistive losses, supports stable signal transmission, and resists grain boundary corrosion. Whether it’s used in transformers, busbars, or semiconductors, this copper material enhances efficiency and minimizes thermal degradation over time. That’s why I choose INT when the application demands flawless quality.

Why should manufacturers trust INT for oxygen free copper strip?

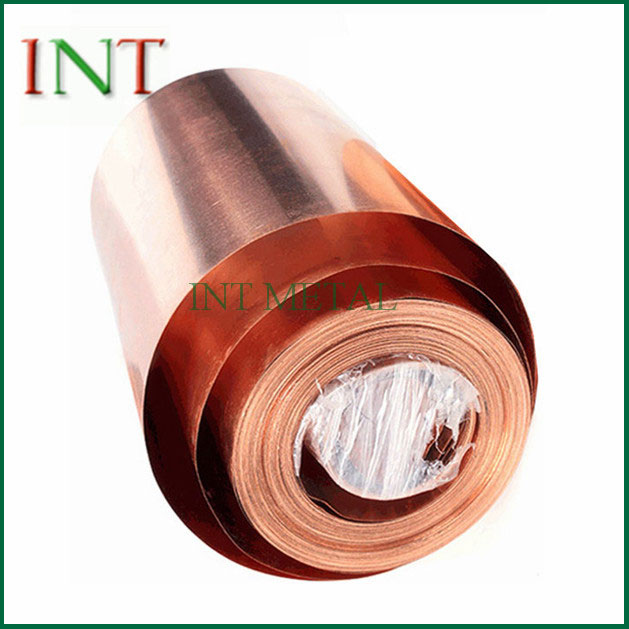

INT stands out in the market for its consistent production standards and advanced processing technology. Their oxygen free copper strip features exceptional surface smoothness, tight dimensional tolerances, and minimal impurities. I’ve specified INT copper strips in multiple projects for aerospace clients, and the feedback has always been positive—zero oxidation, excellent malleability, and easy to work with.

Is oxygen free copper strip suitable for high-temperature or vacuum environments?

Absolutely. One major benefit of oxygen free copper strip is its suitability for environments where even trace oxygen can cause failure. I’ve seen it used in vacuum tubes, electron beam equipment, and cryogenic systems. With INT supplying the material, you can rely on consistent thermal and electrical performance under extreme conditions.

What should engineers consider when sourcing oxygen free copper strip?

Beyond purity, you should consider thickness uniformity, edge precision, and roll-to-roll stability. INT provides oxygen free copper strip in custom sizes and coatings, ensuring compatibility with automated stamping, lamination, and soldering processes.

Looking for high-performance copper solutions for your project?

Then I strongly recommend INT oxygen free copper strip. With proven quality and engineering support, it’s a smart investment for high-spec applications.

Our products are highly reliable. If you have any cooperation or bulk purchase needs, please contact us. We offer 24-hour online quality service.