Why Choose Tensioner Bearings for Your Equipment?

2025-11-11

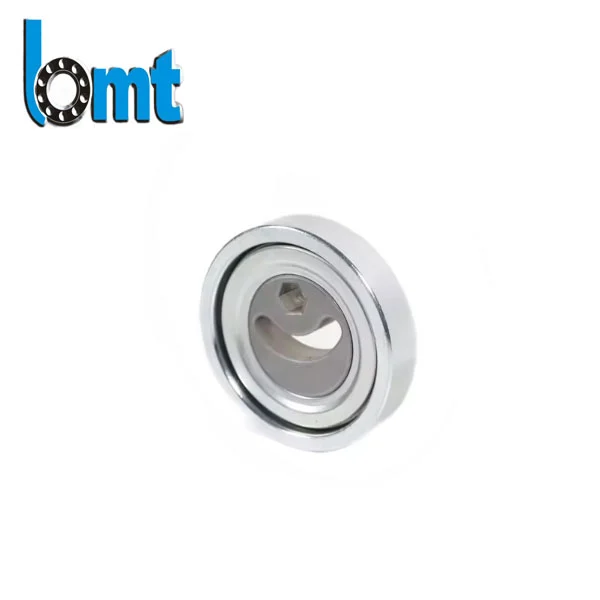

When it comes to ensuring smooth operation in mechanical systems, tensioner bearings play a critical role. At Ningbo Demy (D&M) Bearings Co., Ltd., we specialize in high-quality tensioner bearings designed to meet the diverse needs of various industries. These essential components help to maintain proper tension in a wide range of systems, from automotive engines to industrial machines. In this article, I'll dive into the key aspects of tensioner bearings, their functions, and why they are so important.

What Are Tensioner Bearings and How Do They Work?

Tensioner bearings are specialized components designed to manage and maintain the proper tension in a mechanical system. They are commonly found in systems where belts or chains are used, such as in engines, conveyor systems, and other machines that rely on constant tension for smooth operation.

A tensioner bearing ensures that the tension applied to these belts or chains is consistent, preventing slippage, wear, and misalignment. This helps to maintain optimal performance and extend the lifespan of the components involved.

Why Are Tensioner Bearings Important?

The importance of tensioner bearings cannot be overstated. Without them, systems that rely on tensioned components would experience higher rates of wear and tear, reduced efficiency, and increased maintenance costs.

For example, in automotive engines, a properly functioning tensioner bearing keeps the timing belt or chain under optimal tension, reducing the risk of engine failure. In industrial machinery, tensioner bearings help to ensure that conveyor belts move smoothly without any hiccups or slippage.

The Key Benefits of Tensioner Bearings

-

Enhanced Durability: Tensioner bearings are built to handle the constant stress of tensioning, which significantly reduces wear and tear on other components in the system.

-

Improved Efficiency: By maintaining consistent tension, these bearings help improve the efficiency of the system, allowing for smoother operation and better overall performance.

-

Cost-Effective Maintenance: Regular use of tensioner bearings reduces the likelihood of costly breakdowns or repairs due to improper tension or misalignment.

How Can Tensioner Bearings Be Used Effectively?

Using tensioner bearings effectively depends on selecting the right type for the application and maintaining them properly. It's important to ensure that the bearing is the correct size and type for the system in which it's being used. Regular maintenance is also key, including inspecting the bearing for signs of wear or damage and replacing it when necessary.

Here's a simple table to highlight key specifications for tensioner bearings:

| Specification | Description |

|---|---|

| Material | Steel, Ceramic, or Composite |

| Load Capacity | Depends on size, typically in kilograms |

| Operating Temperature | -30°C to 120°C |

| Lifespan | 100,000 – 200,000 operational hours |

| Lubrication | Grease or oil, depending on application |

Common Applications of Tensioner Bearings

Tensioner bearings are used across a wide variety of industries. Here are some of the most common applications:

-

Automotive Engines: In engines, tensioner bearings help regulate the tension in timing belts and chains, ensuring the engine runs smoothly and efficiently.

-

Industrial Machinery: Conveyor systems and other industrial machines rely on tensioner bearings to keep belts or chains at the right tension, preventing misalignment and maximizing throughput.

-

Agricultural Equipment: Tensioner bearings are also used in agricultural machinery to ensure efficient operation of belt-driven systems.

FAQ: Tensioner Bearings

Q1: How do I know when to replace my tensioner bearing?

A1: It's important to check for signs of wear or noise. If the bearing starts making a grinding or squealing sound, it may be time for a replacement.

Q2: Can I use tensioner bearings in high-temperature environments?

A2: Yes, many tensioner bearings are designed to withstand high temperatures. Be sure to check the specifications for the correct operating temperature range.

Q3: How do tensioner bearings contribute to overall system efficiency?

A3: By maintaining the proper tension, tensioner bearings reduce slippage and wear, which improves the efficiency of the system, lowers maintenance costs, and prolongs the lifespan of components.

Conclusion

Tensioner bearings are essential components for ensuring the efficiency and longevity of mechanical systems across industries. At Ningbo Demy (D&M) Bearings Co., Ltd., we offer high-quality tensioner bearings tailored to meet the specific needs of our customers. Our bearings are designed to provide optimal performance and durability in all kinds of systems.

If you're looking for reliable and durable tensioner bearings for your applications, contact us today to learn more about our products and how we can help optimize your systems.