Why Choose Carbon Steel Coil for Your Industrial Needs?

2025-08-13

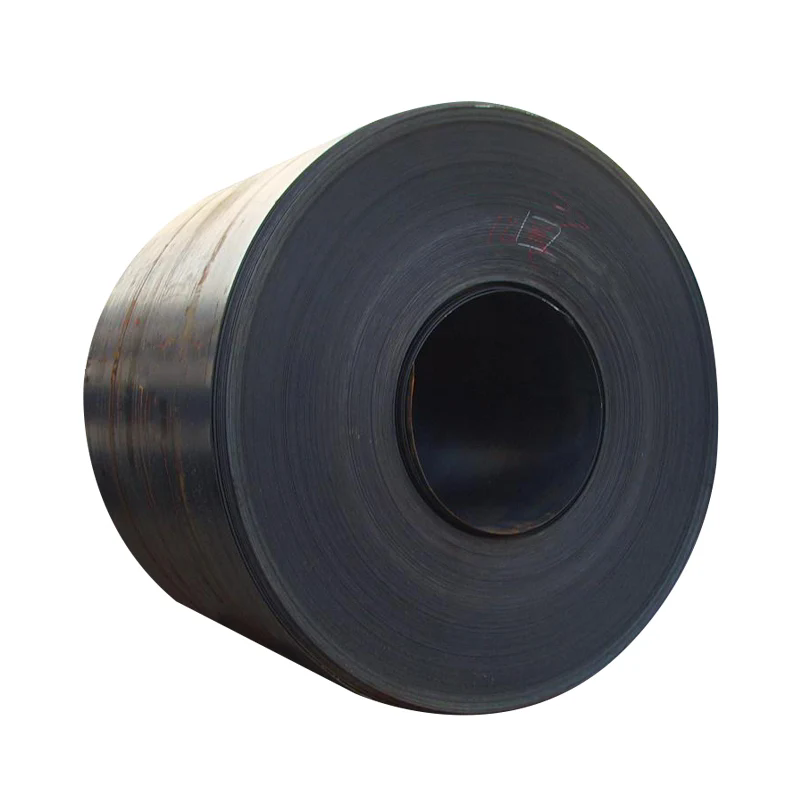

Carbon steel coils are a fundamental material in various industries, from construction to automotive manufacturing. Their durability, cost-effectiveness, and versatility make them a preferred choice for engineers and fabricators worldwide. But what makes carbon steel coils stand out, and how can you select the right one for your project? This guide explores the key benefits, specifications, and common questions to help you make an informed decision.

Carbon steel coils offer several benefits that make them indispensable in industrial applications:

High Strength & Durability – With excellent tensile strength, carbon steel coils withstand heavy loads and harsh conditions.

Cost-Effective – Compared to stainless steel or alloy alternatives, carbon steel is more affordable without compromising performance.

Versatility – Suitable for welding, machining, and forming, making it ideal for automotive, construction, and machinery.

Corrosion Resistance (When Coated) – While raw carbon steel is prone to rust, galvanized or painted variants enhance longevity.

Recyclability – Eco-friendly and reusable, aligning with sustainable manufacturing practices.

Carbon Steel Coil Specifications (Technical Breakdown)To ensure you select the right product, here are the critical parameters to consider:

| Parameter | Details |

|---|---|

| Material Grades | ASTM A36, AISI 1008, 1010, 1018, 1020, Q195, Q235, SPHC, SPHD, etc. |

| Thickness Range | 0.3mm – 20mm (customizable based on requirements) |

| Width Range | 600mm – 2000mm (standard), wider options available upon request |

| Surface Finish | Hot-rolled, cold-rolled, galvanized, painted, or polished |

| Coil Weight | 3 – 20 tons (standard), heavier coils can be produced |

| Standards | ASTM, JIS, DIN, GB, EN, ISO certified |

These specifications ensure compatibility with various industrial demands, from structural beams to precision automotive parts.

Carbon Steel Coil Common Questions (FAQ Section)Q1: What’s the difference between hot-rolled and cold-rolled carbon steel coils?

A: Hot-rolled coils are processed at high temperatures, making them easier to shape but with a rougher surface. Cold-rolled coils undergo additional processing at room temperature, resulting in a smoother finish, tighter tolerances, and higher strength. Cold-rolled steel is often used for precision parts, while hot-rolled is common in construction.

Q2: How can I prevent carbon steel coils from rusting?

A: While untreated carbon steel is prone to oxidation, protective measures include:

Galvanization (zinc coating for corrosion resistance).

Painting/Powder Coating (adds a protective layer).

Oiling (temporary solution during storage/transport).

Storing in dry, low-humidity environments.

Why Trust Wanhetong for Your Carbon Steel Coil Needs?At Wanhetong, we specialize in high-quality carbon steel coils tailored to your industrial requirements. With decades of expertise, we ensure:

Strict Quality Control – Every coil meets international standards (ASTM, JIS, DIN).

Custom Solutions – Adjustable thickness, width, and surface treatments.

Competitive Pricing – Cost-efficient without compromising durability.

Global Shipping – Reliable logistics for timely delivery.

Contact Us !

Looking for premium carbon steel coils? Wanhetong provides expert consultation and tailored solutions. Reach out for a quote or technical support:

By choosing Wanhetong, you invest in reliability, performance, and long-term value for your projects. Let’s build the future with superior steel solutions!