Why can sheet metal shells be a solid protection for equipment?

2025-07-25

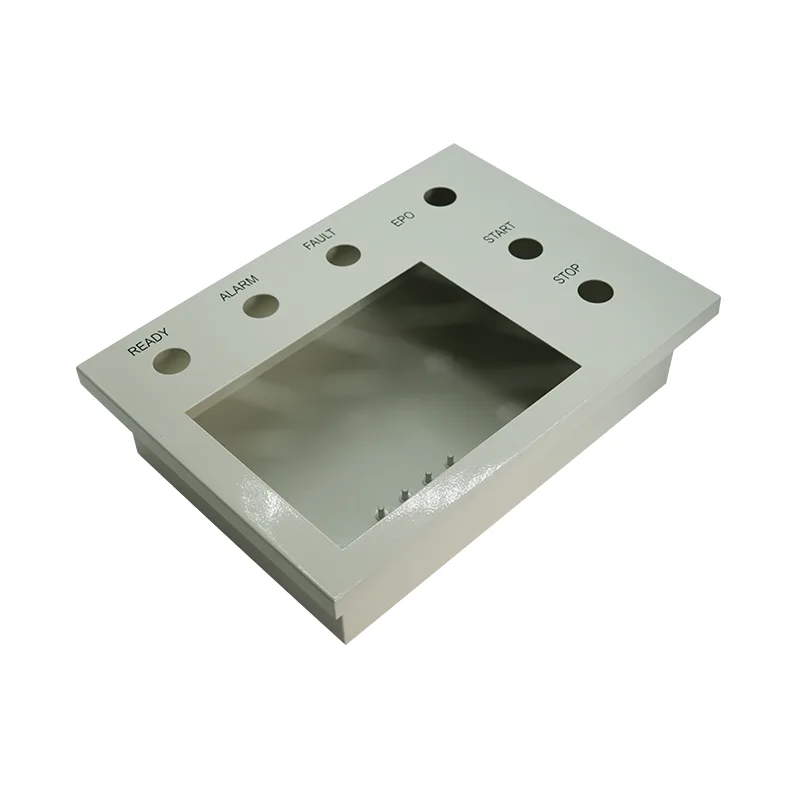

With its precise protection performance and flexible form adaptability, sheet metal shells have become the key to protecting the core components of equipment and realizing functional extension. It can not only resist external impact, dust and moisture, but also present a variety of structural forms according to equipment requirements. Its material selection and processing technology directly affect the safety and practicality of the equipment.

Protection logic of material selection

The protective ability of sheet metal shells first comes from reasonable material selection. Common cold-rolled steel plates have high strength and toughness, which can effectively buffer the impact force when hit by external forces and protect internal components from damage; galvanized steel plates rely on the zinc layer on the surface to form a passivation film, which greatly improves the corrosion resistance of the shell and is suitable for use in humid or dusty environments. The characteristics of different materials are accurately matched to the use scenarios of the equipment. From industrial machine tools to medical instruments, corresponding protection solutions can be found to ensure that the shell maintains stable protective performance in long-term use.

Morphological shaping power of processing technology

Advanced processing technology gives sheet metal shells powerful morphological shaping capabilities. Laser cutting technology can achieve high-precision contour cutting, so that the openings and bends of the shell meet the design dimensions and fit perfectly with the internal components of the equipment; CNC bending technology can bend flat plates into complex three-dimensional structures to meet the compact space utilization requirements of the equipment. This process precision not only ensures the sealing of the shell to prevent dust and liquid intrusion, but also reserves heat dissipation holes and interface positions through reasonable structural design, taking into account the protection function and the convenience of equipment operation.

The practical value of functional adaptation

The value of sheet metal shell lies not only in protection, but also in the deep adaptation with the function of the equipment. For large equipment, the shell can be designed into a detachable modular structure to facilitate later maintenance and repair; for small precision instruments, the shell can be made thin and light, reducing the overall volume of the equipment without affecting the protection performance. At the same time, surface treatment processes such as spraying and electrophoresis can not only improve the beauty of the shell, but also enhance its wear resistance, so that the equipment has a longer service life while maintaining functionality.

Shenzhen Zhongyilong Hardware Products Co., Ltd. relies on its rich experience in the field of precision manufacturing and focuses on providing high-quality sheet metal shell solutions. The company focuses on strict screening of materials and precise control of processing technology to ensure that each shell can achieve reliable protection performance and flexible form adaptation. Whether it is industrial equipment or consumer electronics, it can create a suitable "sturdy coat" for it to help the equipment operate stably in various scenarios.