Why Are Modern Conveyor Belts Transforming Material Handling Efficiency?

2025-10-17

In an era of automation and high-throughput manufacturing, conveyor belts form the backbone of material handling systems across industries. Conveyor belts are continuous loops of material that transport goods and materials between locations.

What Are Conveyor Belts — Types, Parameters, Applications

Conveyor belts are mechanical systems composed of a flexible belt loop stretched between pulleys and supported by rollers or slide beds, enabling continuous transport of items. They are widely used in industries such as logistics, mining, food processing, packaging, manufacturing, airports, and warehousing.

Types of Conveyor Belts

-

Flat belt conveyors — smooth-surface belts used in general material transport

-

Modular plastic belts — interlocking plastic segments, ideal for washdown and food

-

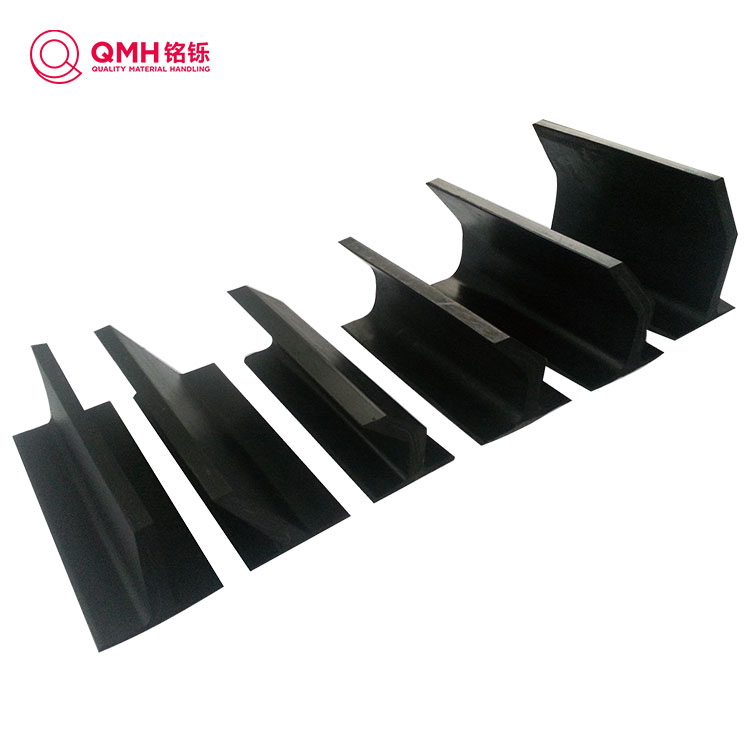

Cleated belts — belts with raised cleats for inclined transport

-

Timing belts (synchronous belts) — toothed belts for precise positional control

-

Steel cord or fabric-reinforced belts — heavy-duty belts for mining or heavy loads

-

Slider or troughed belt conveyors — belts on idler sets that form a trough shape for bulk materials

Key Product Parameters

Below is a representative product parameter table. Actual specs may vary by model and customer requirements.

| Parameter | Typical Value / Range | Notes / Importance |

|---|---|---|

| Belt width | 300 mm to 2,400 mm (or more) | Depends on throughput and package dimensions |

| Belt speed | 0.2 to 5 m/s (higher in special applications) | Affects throughput rate |

| Material thickness | 2 mm to 12 mm (or higher) | Strength and durability |

| Tensile strength | 400 N/mm to 3,200 N/mm or more | Governs load capacity, elongation |

| Pulley diameter | 100 mm to 500 mm or more | Influences bending stress and belt life |

| Drive power | 0.5 kW to 50 kW or more | Determined by load and speed |

| Working temperature | –20 °C to 80 °C (or wider for specialty belts) | For material compatibility |

| Coefficient of friction | 0.2 to 0.6 (depending on belt surface) | Affects grip and slip with conveyed items |

These parameters collectively determine conveyor belt performance in strength, speed, loading, durability, flexibility, and environmental compatibility.

Key Applications

-

In manufacturing lines for movement of parts between workstations

-

In distribution centers for sorting, accumulation, and parcel conveyance

-

In mining/quarry for bulk material transport

-

In food and beverage for moving packaged goods or ingredients

-

In airport baggage handling systems

Why Conveyor Belts Are Essential Today

Understanding why conveyor belts remain vital helps clarify criteria for selection, optimization, and investment decisions.

Enhance Throughput and Efficiency

Conveyor belts drastically reduce manual handling, enabling continuous, high-volume, and predictable movement of goods. This leads to increased cycle rates and scalable operations.

Reduce Labor Costs and Injury Risk

Automation with conveyors lessens reliance on manual labor, reducing repetitive motion injuries and associated labor cost variability.

Improve System Integration and Automation

Belts can be integrated with sensors, robots, sorting systems, and control software, enabling Industry 4.0 connectivity and data-driven material flow.

Support Heavy Loads and Harsh Environments

Modern reinforced belts (steel cord, fabric) allow transport of heavy loads over long distances, while specialty coatings (e.g. PU, PVC, thermoplastic) offer resistance to oils, chemicals, abrasion, or hygiene standards.

Flexibility of Layouts

Belts can be curved, inclined, declined, or modular, allowing versatile plant layout and space utilization.

Energy Efficiency and Low Maintenance

With optimized design, conveyor belts can run with low energy consumption per unit transported. Maintenance is typically lower than alternative transport (e.g. forklifts) when properly designed and maintained.

How to Select, Implement, Maintain, and Optimize Conveyor Belts

This section explains how to approach conveyor belt selection, installation, maintenance, and future-proofing.

Selection Criteria & Steps

-

Define load characteristics: weight, shape, material type, surface friction

-

Determine throughput requirement: units per hour, belt speed

-

Layout constraints: length, incline, curves, height changes

-

Environmental conditions: temperature, humidity, chemicals, washdown

-

Belt material compatibility: PU, PVC, rubber, modular plastic, steel cord

-

Safety and regulatory compliance: food-grade, fire rating, electrostatic

-

Drive and control design: motor sizing, variable speed drives, starting torque

-

Support structure and idlers design: spacing, type (roller, slider), troughing

-

Redundancy and spare parts planning: for critical lines

-

Cost vs ROI analysis: lifetime cost, energy, downtime, replacement

Installation Best Practices

-

Pre-tensioning and alignment to prevent edge wear

-

Proper tracking adjustment

-

Correct pulley and idler alignment

-

Controlled belt start-up to avoid jerk loads

-

Guarding, covers, and safety sensors

Maintenance & Troubleshooting

-

Regular inspection: look for wear, tears, fraying, misalignment

-

Cleaning: remove debris, buildup, ensure belt surface condition

-

Lubricate bearings in idler rollers

-

Check belt tension and retension as required

-

Replace worn parts promptly (idler, pulley lagging, scrapers)

-

Monitor belt elongation and splices

Common issues and remedies:

-

Belt tracking off center → adjust idler positions or belt edge guides

-

Slippage under load → increase tension or use high-friction surface

-

Fracture at splice → check splice quality, reduce shock loading

-

Noise or vibration → inspect rollers, bearings, misalignment

Optimization & Upgrades

-

Use sensors and PLCs for predictive maintenance

-

Implement variable speed drives (VSD) to adapt speed to load

-

Use lightweight high-strength belt materials to reduce inertia

-

Modular designs for easier expansion or reconfiguration

-

Energy recovery or regenerative drives in elevation change belts

-

Surface coatings for reduced friction or improved grip

Emerging Trends & Future Outlook

-

IoT-based monitoring: belts with embedded sensors for temperature, vibration, elongation

-

Smart materials: self-cleaning, self-healing belt surfaces

-

Sustainability: belts built with recycled or bio-based polymers

-

Modular robotics integration: conveyors working alongside mobile robots

-

Lightweight high-strength composites replacing heavier belts

Frequently Asked Questions (FAQs)

What is the typical lifetime of a conveyor belt under normal conditions?

Lifetime varies widely depending on load, environment, tensioning, and maintenance. Under optimal conditions, a well-chosen belt can last 5 to 10 years or more. Harsh environments or high loads may reduce lifetime to 2–4 years.

How to choose between modular plastic belt and traditional rubber belt?

Choose modular plastic belts when washdown, hygiene, flexibility, or breaking down for cleaning is priority (e.g., food, beverage). Use rubber or reinforced rubber belts when you need higher tensile strength, impact resistance, or operate under abrasive conditions.

Conclusion & Forward Look

Conveyor belts play an indispensable role in modern material handling, offering efficiency, reliability, flexibility, and scalability. When selecting your conveyor belt solutions, it is advisable to partner with a reputable manufacturer that offers tailored design, quality assurance, and after-sales support. QMH stands ready to deliver advanced conveyor belt systems suited to your operational needs, combining industry expertise with innovation. For more information or a custom quote, contact us.