Why Are Flat Oval Tubes Becoming a Smarter Choice for Modern Heat Transfer Systems?

2026-01-12

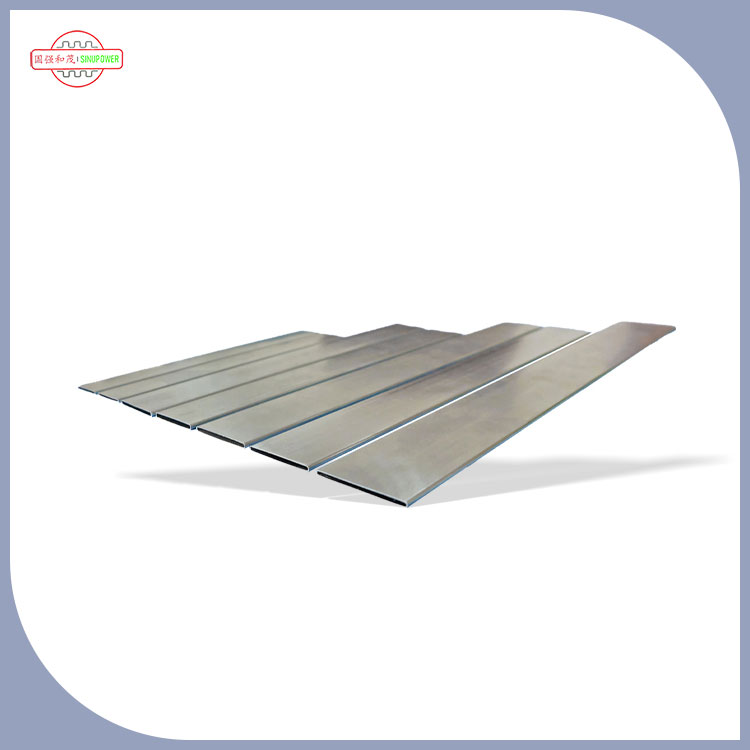

When I first started working closely with manufacturers in HVAC and industrial heat exchange, I kept hearing the same complaints repeated in different ways: inefficient airflow, limited space, rising energy costs, and designs that no longer matched modern equipment requirements. It was during these conversations that Sinupower naturally entered my field of view, not as a loud brand name, but as a practical solution provider. Their gradual focus on Flat Oval Tubes felt like a response to real engineering frustrations rather than a marketing trend.

What Problems Do Flat Oval Tubes Actually Solve in Real Applications?

From my experience, traditional round tubes still dominate many systems simply because they are familiar. But familiarity does not always equal efficiency. Flat Oval Tubes address several pain points that engineers and buyers regularly struggle with, especially when space, airflow, and performance must be balanced at the same time.

- They reduce air-side resistance, which helps systems operate with lower fan power.

- The flattened profile allows more compact coil designs without sacrificing capacity.

- Heat transfer performance improves due to increased contact surface with fins.

- They support lightweight structures, which matters for transport and installation.

How Do Flat Oval Tubes Improve Heat Transfer Efficiency Without Increasing Costs?

One of the biggest misconceptions I encounter is that higher efficiency always means higher cost. In reality, Flat Oval Tubes often reduce overall system expenses. By optimizing the tube shape, manufacturers can achieve better thermal performance using less material and lower operating energy.

| Performance Aspect | Conventional Round Tubes | Flat Oval Tubes |

|---|---|---|

| Airflow Resistance | Moderate to High | Lower and more stable |

| Heat Transfer Area | Limited by shape | Optimized contact with fins |

| Material Utilization | Less efficient | More effective per unit length |

| System Energy Consumption | Higher fan demand | Reduced operating load |

Why Are Designers Choosing Flat Oval Tubes for Compact and Lightweight Equipment?

Space limitations are no longer a special case; they are the norm. Whether it is rooftop units, transport refrigeration, or compact industrial chillers, every millimeter matters. I have seen design teams switch to Flat Oval Tubes simply because the geometry allows tighter coil spacing and slimmer assemblies without compromising performance.

- More flexible layout options for dense heat exchanger designs.

- Reduced coil depth while maintaining thermal output.

- Better compatibility with modern fin structures.

- Lower overall unit weight, easing installation and maintenance.

How Do Flat Oval Tubes Support Long-Term Reliability and Manufacturing Stability?

Reliability is often overlooked in early design stages, yet it directly affects lifecycle cost. In my discussions with production teams, Flat Oval Tubes stand out for their consistency in forming, brazing, and assembly. The shape distributes stress more evenly under airflow and thermal cycling, which helps extend service life.

Manufacturers like Sinupower also tend to focus on tight dimensional control and material consistency, which reduces variation during mass production. This stability translates into fewer defects, smoother assembly lines, and predictable performance in the field.

Is Switching to Flat Oval Tubes the Right Move for Your Next Project?

Every project has its own constraints, but when energy efficiency, compact design, and long-term reliability are on the priority list, Flat Oval Tubes deserve serious consideration. I have watched many teams hesitate at first, only to realize later that the transition solved multiple issues at once rather than creating new ones.

If you are evaluating tube solutions for upcoming heat exchanger designs and want to explore how Flat Oval Tubes can fit your technical and commercial goals, now is the right time to take the next step. Contact us to discuss your application requirements, request technical support, or send an inquiry directly to start a more efficient solution conversation.