Why Are Copper Fittings the Preferred Choice for Modern Plumbing Systems?

2025-11-13

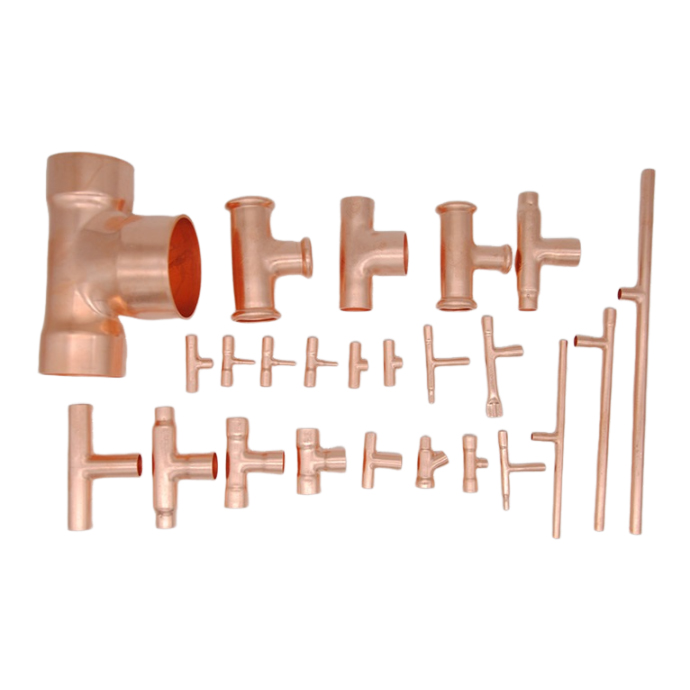

Copper fittings are critical components used to connect, terminate, control, or change the direction of copper piping in plumbing systems. They ensure tight and leak-free connections, providing reliability and efficiency in both residential and industrial applications. Known for their exceptional durability and resistance to corrosion, copper fittings have become a standard in plumbing, HVAC, and gas distribution networks.

In modern construction and renovation projects, copper fittings continue to play a vital role due to their combination of thermal conductivity, malleability, and longevity. They can withstand extreme temperatures, high pressure, and chemical exposure, making them suitable for diverse conditions. From simple elbow joints to complex multi-connection tees, copper fittings enhance fluid transfer and system performance while minimizing maintenance needs.

Key Product Parameters

| Parameter | Specification |

|---|---|

| Material Composition | 99.9% Pure Copper (Cu-DHP or Cu 99.9%) |

| Size Range | 1/4 inch – 6 inches |

| Working Temperature | -100°C to +250°C |

| Pressure Rating | Up to 400 PSI |

| Fitting Types | Elbow, Tee, Coupling, Reducer, Adapter, Cap |

| Standard Compliance | ASTM B88, ASME B16.22, EN 1254 |

| Surface Finish | Bright, Smooth, and Deburred |

| Connection Type | Soldering, Press-fit, or Compression |

| Applications | Plumbing, HVAC, Refrigeration, Gas Systems |

Copper fittings provide an ideal balance of strength, conductivity, and resistance to environmental degradation. Their seamless design minimizes potential leakage points, while their compatibility with existing copper pipes makes them universally adaptable. This combination of features contributes to their popularity across residential, commercial, and industrial sectors.

Why Are Copper Fittings Preferred Over Other Materials?

The choice of copper fittings over alternatives such as PVC, PEX, or stainless steel is driven by several practical and performance-based factors. Copper has a long history of use in plumbing due to its proven reliability, safety, and sustainability. It offers several key advantages that continue to make it a top choice for professionals.

1. Durability and Longevity

Copper fittings can last more than 50 years under normal operating conditions. They resist wear, corrosion, and deformation, even under high-pressure or high-temperature applications. Unlike plastic fittings, copper does not degrade under UV exposure or temperature fluctuations.

2. Excellent Thermal Conductivity

Copper’s high thermal conductivity ensures efficient heat transfer, making it ideal for both hot and cold water systems, as well as heating and cooling systems in HVAC applications.

3. Corrosion Resistance and Hygiene

Copper naturally resists bacterial growth, which makes it suitable for drinking water systems. It also forms a thin oxide layer that prevents corrosion, maintaining water purity and flow efficiency over time.

4. Fire Resistance and Safety

Copper fittings are non-combustible and have a high melting point. They do not emit toxic gases when exposed to fire, offering a safer and more reliable option for building infrastructure.

5. Sustainability and Recyclability

Copper is 100% recyclable without any loss of performance. The use of recycled copper fittings significantly reduces environmental impact, aligning with global trends toward eco-friendly construction materials.

In contrast, alternative materials like PEX may degrade over time or release microplastics into the water supply. Copper’s natural and sustainable properties make it a preferred solution for engineers and builders seeking reliability and compliance with modern safety standards.

How Are Copper Fittings Used Across Different Industries?

The versatility of copper fittings extends beyond plumbing. Their adaptability and performance make them essential in various sectors. Understanding how these fittings are used provides a clear picture of their industrial importance and the innovation surrounding their design.

1. Residential Plumbing Systems

Copper fittings are commonly used in homes for both hot and cold water supply lines. Their leak-proof connections and long lifespan make them a reliable choice for homeowners. Copper’s resistance to corrosion ensures consistent water flow and pressure.

2. HVAC and Refrigeration

In heating, ventilation, and air conditioning systems, copper fittings help connect coils, compressors, and condensers. Their thermal properties allow efficient heat exchange, reducing energy consumption and improving performance.

3. Gas and Fuel Distribution

Copper’s resistance to chemicals and gases makes it ideal for gas piping and fuel systems. It provides a secure, leak-free connection, ensuring safety in both domestic and industrial environments.

4. Industrial and Manufacturing Applications

Copper fittings are widely used in process industries, chemical plants, and manufacturing lines where fluids and gases must be transported under strict temperature and pressure conditions.

5. Renewable Energy Systems

As solar and geothermal heating systems become more popular, copper fittings are being integrated into renewable energy pipelines due to their ability to handle heat transfer efficiently.

6. Marine and Automotive Sectors

In marine and automotive engineering, copper fittings are used in cooling, hydraulic, and fuel systems. Their anti-corrosive nature ensures reliability even in harsh saltwater environments.

Installation and Maintenance

Installing copper fittings requires proper cleaning, fluxing, and soldering or press-fitting techniques to ensure leak-free performance. Once installed, they demand minimal maintenance, offering long-term reliability and cost efficiency.

What Are the Future Trends and Innovations in Copper Fittings?

The copper fittings industry continues to evolve with advancements in technology and sustainability. Global infrastructure modernization, water conservation efforts, and green building initiatives are driving innovation.

1. Smart Plumbing and Press-Fit Technology

The rise of press-fit copper fittings is transforming installation methods. These fittings use mechanical pressing rather than soldering, reducing installation time and eliminating fire hazards. They are widely used in high-rise buildings and commercial projects.

2. Lead-Free and Eco-Friendly Alloys

Manufacturers are focusing on producing lead-free copper alloys to comply with international safety standards, ensuring safe drinking water and environmental protection.

3. Improved Manufacturing Precision

With advanced CNC machining and seamless extrusion technologies, copper fittings are becoming more accurate and uniform, ensuring better sealing and performance in modern systems.

4. Integration with Renewable Energy

Copper’s high conductivity and temperature resistance make it an excellent choice for future energy solutions such as solar water heating and heat pump systems.

5. Recycling and Sustainability Focus

As the global demand for sustainable materials grows, recycled copper fittings are becoming more popular. This trend supports circular economy principles and reduces carbon emissions.

6. Global Market Growth

With the expansion of urban infrastructure and the replacement of aging plumbing networks, the copper fittings market is expected to grow steadily. Asia-Pacific, Europe, and North America remain the key markets due to ongoing residential and commercial development.

Copper fittings are not just components; they are a foundation of modern plumbing technology. As new innovations emerge, the future of copper fittings looks promising, focusing on energy efficiency, environmental sustainability, and technological integration.

Common FAQs About Copper Fittings

Q1: What makes copper fittings more durable than plastic or steel fittings?

Copper fittings are made from high-purity copper, which provides natural resistance to corrosion, temperature variations, and chemical reactions. Unlike plastic, copper does not become brittle over time or release harmful particles. Compared to steel, it does not rust or oxidize when exposed to water. This makes copper fittings more reliable and long-lasting, even in high-pressure or high-temperature environments.

Q2: How should copper fittings be maintained for long-term use?

Maintenance for copper fittings is minimal. Regularly inspect connections for leaks or buildup, especially in older installations. If properly installed with quality flux and solder, copper fittings can last decades without significant maintenance. Cleaning with mild solutions and avoiding abrasive chemicals helps preserve their smooth surface and prevent scaling.

Copper fittings continue to set the industry standard for quality, performance, and sustainability. They provide unmatched strength, resistance to corrosion, and efficiency in heat and fluid transfer. From residential plumbing to industrial systems, their reliability ensures long-lasting performance and cost-effective operation.

With decades of expertise in manufacturing precision-engineered copper fittings, Gangxin stands as a trusted supplier dedicated to providing high-quality, eco-friendly, and durable copper connection solutions for global markets. Whether for plumbing, HVAC, or industrial applications, Gangxin’s products are designed to meet international standards and evolving market needs.

For more information or to discuss customized copper fitting solutions for your business, contact us today to learn how Gangxin can support your next project with professional-grade copper products.