What Makes Switchgear Static Contact Essential for Reliable Power Distribution?

2025-12-08

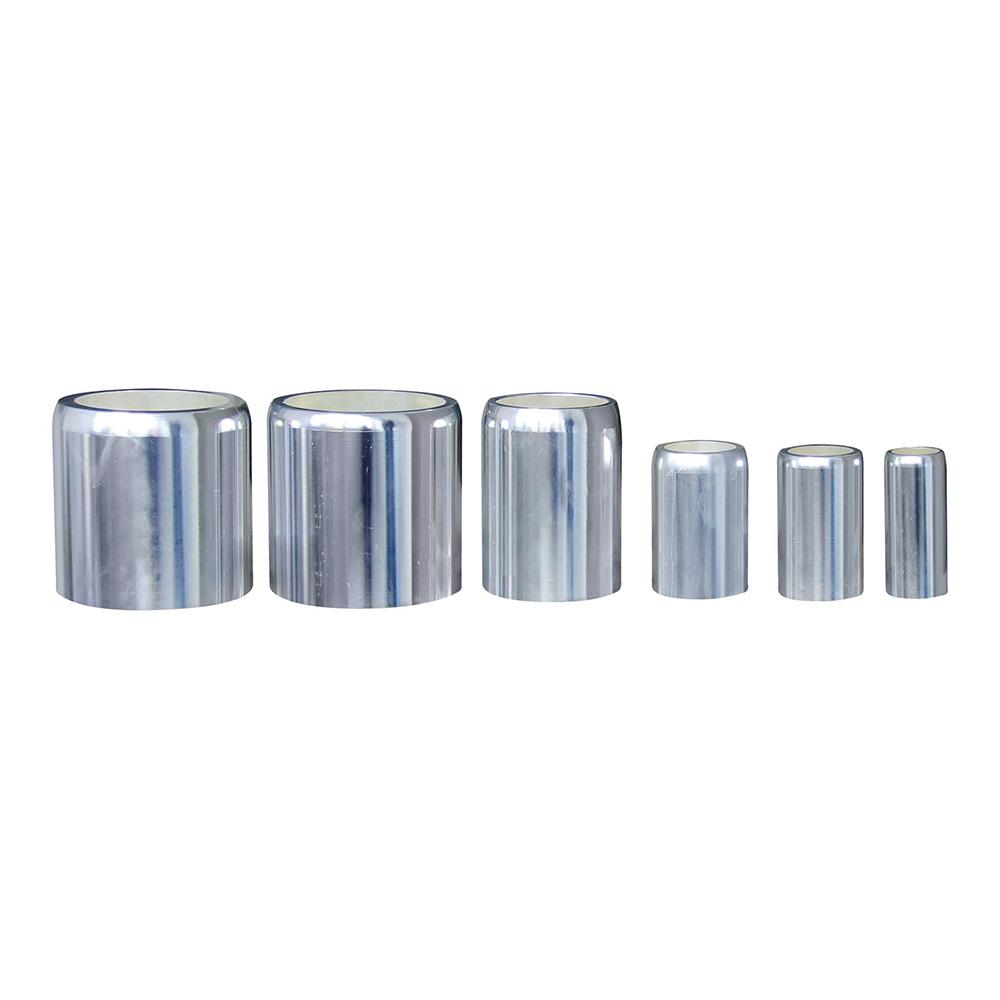

As modern electrical systems continue to evolve, the demand for stable, safe, and efficient power distribution has grown rapidly. Switchgear Static Contact plays a decisive role in determining the overall performance of switchgear assemblies. Backed by years of industry experience, Ningbo Richge Technology Co., Ltd. delivers high-precision static contacts engineered for durability, conductivity, and long-term reliability. In this article, I explain the functions, benefits, and performance of Switchgear Static Contact, and explore why it remains a critical component for industrial and commercial power protection.

Understanding the Role of Switchgear Static Contact

Static contacts are fixed conductive elements inside switchgear used to maintain electrical continuity when paired with moving contacts. Their design quality directly affects system stability.

Main Functions

-

Provide stable electrical conduction

-

Enable smooth opening and closing of circuits

-

Reduce contact resistance and heat accumulation

-

Improve overall switchgear lifespan

-

Enhance system safety in high-current applications

Why Is Switchgear Static Contact Important?

The static contact is the foundation of switchgear performance. Without a reliable static contact, high-voltage and high-current systems may suffer from overheating, voltage drop, or operational failure. At Ningbo Richge Technology Co., Ltd., we design each component to meet strict mechanical strength and conductivity standards to ensure the highest protection level.

Technical Parameters of Our Switchgear Static Contact

Below is a simple technical table demonstrating the specifications we commonly offer:

| Parameter | Specification Range |

|---|---|

| Material | Copper, Silver-plated Copper, Alloy |

| Conductivity | ≥ 98% IACS |

| Rated Voltage | 400V – 40.5kV |

| Rated Current | 400A – 4000A |

| Contact Resistance | ≤ 0.5 mΩ |

| Operating Temperature | –40°C to 120°C |

| Surface Treatment | Silver Plating, Tin Plating |

Effects and Performance of Switchgear Static Contact

A well-designed static contact brings significant operational advantages:

-

Low resistance, ensuring smooth power flow

-

Excellent heat dissipation, preventing thermal damage

-

High mechanical stability, suitable for repeated operations

-

Corrosion-resistant surface, improving long-term conductivity

-

Enhanced electrical safety, reducing arc-related risks

Which Features Should You Prioritize When Choosing a Switchgear Static Contact?

When selecting the right product for your system, consider the following key factors:

-

Material Purity – Higher purity copper ensures better conductivity.

-

Surface Coating – Silver plating minimizes oxidation and resistance.

-

Mechanical Fit – Must align accurately with the moving contact.

-

Current Rating – Match the rated load of your switchgear.

-

Manufacturer Expertise – Choose suppliers like Ningbo Richge Technology Co., Ltd. who specialize in precision electrical components.

Q&A Section: Three Key Questions I Frequently Encounter

Q1: Why do I need high-precision Switchgear Static Contact?

A1: Because precision ensures low resistance, stable performance, and lower heat generation, which improves operational safety.

Q2: How can I extend the lifespan of my Switchgear Static Contact?

A2: I recommend choosing silver-plated contacts and ensuring your switchgear is regularly maintained to reduce oxidation and wear.

Q3: What should I check before replacing a Switchgear Static Contact?

A3: In my experience, you should verify compatibility, material, and rated current to ensure your replacement part matches system requirements.

List: Advantages of Choosing Ningbo Richge Technology Co., Ltd.

-

High-precision manufacturing

-

Strict quality control

-

Customizable specifications

-

Silver-plated and alloy options

-

Competitive pricing for bulk orders

-

Fast delivery and professional support

Conclusion

Switchgear Static Contact is a critical component that directly influences electrical safety, reliability, and switching efficiency. Choosing the right contact means choosing stability, and Ningbo Richge Technology Co., Ltd. is committed to providing superior-quality components that guarantee long-term performance.

If you are looking for reliable switchgear components or want customized solutions, contact us today to get professional assistance and competitive quotations.