What Makes Stainless Steel Heat Exchanger Pipes a High-Performance Choice for Modern Thermal Systems?

2025-11-18

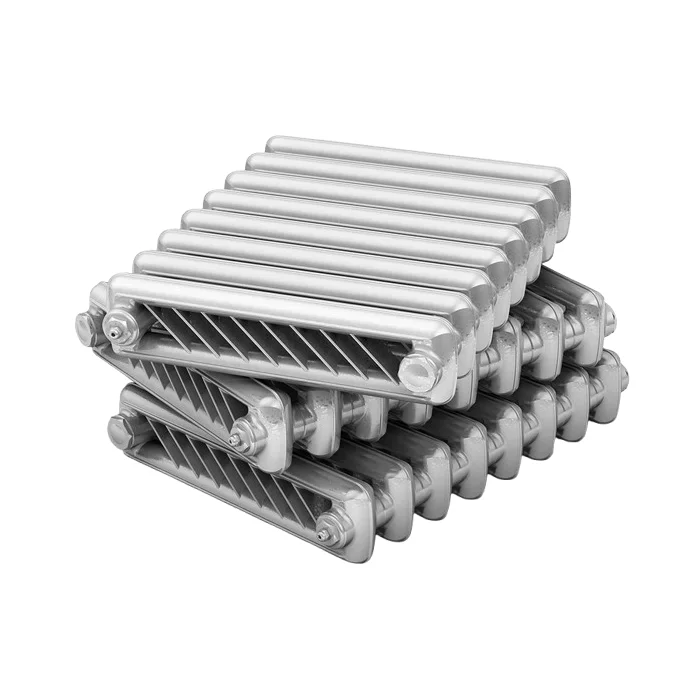

A stainless steel heat exchanger pipe is a specialized industrial tube engineered to transfer heat efficiently between two mediums—liquid, gas, or a combination of both. It is widely used in HVAC systems, chemical processing, power generation, food and beverage manufacturing, marine engineering, and petroleum applications. Its purpose is to enhance heat transfer efficiency, minimize energy loss, maintain durability under extreme operating conditions, and reduce long-term maintenance costs.

Why Stainless Steel Heat Exchanger Pipes Offer Superior Performance

Stainless steel heat exchanger pipes are engineered with unique physical and chemical properties that deliver exceptional value in harsh environments. Their advantages are driven by the intrinsic strength of stainless steel alloys, their corrosion resistance, and their structural stability under fluctuating temperatures.

Corrosion Resistance and Material Stability

Corrosion is one of the major threats to heat exchanger performance. Stainless steel pipe grades—such as 304, 316L, 321, and 2205 duplex—provide outstanding resistance to:

-

Chlorides

-

Acids

-

Alkalis

-

High-humidity environments

-

Marine atmosphere

This resistance results in significantly longer service life and reduced risk of leakage or contamination, especially in chemical and food-grade processing.

Exceptional Thermal Conductivity and Efficiency

While copper is traditionally known for high thermal conductivity, stainless steel offers balanced heat transfer performance along with stability and mechanical strength. Its conductivity remains consistent under:

-

High temperatures

-

Rapid temperature fluctuations

-

Pressure changes

This allows the pipe to maintain high operational efficiency without deformation.

Mechanical Strength Under Extreme Conditions

Heat exchanger pipes must withstand internal and external pressure while carrying hot fluids or gases. Stainless steel materials maintain structural integrity even when exposed to:

-

Pressures exceeding 10 MPa

-

Temperatures between –200°C and 800°C

-

Mechanical stress and vibration

This ensures stable long-term operation in boilers, condensers, evaporators, and energy systems.

Hygiene and Safety for Sensitive Applications

Stainless steel surfaces resist bacterial growth and chemical leaching. This makes them ideal for industries where purity is critical, such as:

-

Food and beverage

-

Dairy

-

Pharmaceuticals

-

Medical equipment cooling systems

The smooth inner wall enhances fluid flow, minimizes scaling, and improves overall thermal efficiency.

What Are the Core Product Parameters of Stainless Steel Heat Exchanger Pipes?

The following table provides a concise overview of the typical technical specifications used in industrial projects:

| Parameter | Specification Range |

|---|---|

| Material Grades | 304, 304L, 316, 316L, 321, 2205 duplex |

| Outside Diameter | 6 mm – 219 mm |

| Wall Thickness | 0.5 mm – 12 mm |

| Length | 1 m – 12 m or customized |

| Manufacturing Process | Seamless / Welded |

| Surface Finish | Annealed, pickled, polished |

| Pressure Rating | Up to 10–25 MPa depending on grade |

| Temperature Range | –200°C to 800°C |

| Standard Compliance | ASTM A213, ASTM A249, ASTM A269, EN10216-5 |

These parameters define key performance characteristics that influence heat transfer efficiency, durability, and system compatibility. When selecting the right stainless steel heat exchanger pipe, engineers typically evaluate corrosion environment, pressure requirements, thermal performance expectations, and long-term maintenance planning.

How Do Stainless Steel Heat Exchanger Pipes Function in Modern Industrial Systems?

A stainless steel heat exchanger pipe functions through direct or indirect heat transfer. Its efficiency is defined by material composition, wall thickness, internal smoothness, and arrangement within the exchanger unit.

Fluid Flow and Surface Contact

Heat is exchanged when the hot and cold mediums flow through separate passages divided by stainless steel pipe walls. The smooth interior improves fluid velocity, reduces energy consumption, and enhances overall system performance.

High Thermal Shock Tolerance

Industries such as petrochemical processing and power generation require rapid transitions from cold to hot temperatures. Stainless steel resists:

-

Cracking

-

Deformation

-

Thermal fatigue

This improves the lifespan of boilers, superheaters, and condensers.

Compatibility With Multiple Heat Exchanger Types

Stainless steel pipes are suited for:

-

Shell-and-tube heat exchangers

-

Plate heat exchangers (as external piping)

-

Air coolers

-

Condensers and evaporators

-

Waste heat recovery units

-

Industrial chillers

Their versatility makes them essential across diverse engineering applications.

Low Maintenance and Long Service Life

Compared with carbon steel or copper-nickel pipes, stainless steel requires less frequent maintenance because of its resistance to:

-

Scaling

-

Rust

-

Pitting

-

Stress-corrosion cracking

As a result, overall operational costs decrease significantly over the system’s lifespan.

Why Are Stainless Steel Heat Exchanger Pipes Becoming More Relevant for the Future?

The demand for stainless steel heat exchanger pipes continues to rise as industries seek more sustainable, energy-efficient, and long-lasting materials.

Global Shift Toward Higher Efficiency

Energy optimization is a major priority. Stainless steel supports:

-

Reduced energy loss

-

Improved thermal transfer reliability

-

Stable performance under renewable energy systems

Heat exchangers in solar thermal, geothermal, and hydrogen energy sectors increasingly rely on stainless steel pipes.

Compliance With Environment-Focused Regulations

Industries face stricter rules regarding:

-

Contamination control

-

Emissions

-

Waste reduction

Stainless steel’s recyclability aligns perfectly with environmental priorities, making it a preferred material for greener engineering solutions.

Advancements in Metallurgical Technology

Modern production methods—such as precision welding, seamless extrusion, and improved alloy formulations—are delivering:

-

Better corrosion resistance

-

Higher heat tolerance

-

Lighter wall thickness with stronger mechanical properties

-

More cost-effective manufacturing

These improvements increase the performance-to-cost ratio and accelerate adoption across new industries.

Growing Use in Harsh and High-Temperature Environments

With industries pushing toward more extreme operating conditions, stainless steel becomes indispensable for:

-

Oil refining

-

Chemical reactors

-

High-pressure steam systems

-

Waste heat boilers

-

Offshore marine applications

Its reliability contributes to safer and more efficient system operation.

Common FAQs About Stainless Steel Heat Exchanger Pipes

Q1: What grade of stainless steel is best for high-corrosion environments in heat exchanger applications?

A: The best grade for high-corrosion environments—especially those containing chlorides—is typically 316L, due to its molybdenum content that enhances pitting and crevice corrosion resistance. In more aggressive chemical processing environments, 2205 duplex stainless steel provides even better resistance thanks to its dual-phase microstructure, making it suitable for marine, petrochemical, and desalination systems.

Q2: How long can a stainless steel heat exchanger pipe last under continuous high-temperature operation?

A: A stainless steel heat exchanger pipe can last 15 to 30 years or longer, depending on the grade and operating conditions. Grades like 321 or 316L maintain mechanical strength and corrosion resistance even when exposed to temperatures of 600°C–800°C. Proper installation, routine flushing, and fluid quality control further extend the service lifespan.

Why Stainless Steel Heat Exchanger Pipes Remain the Ideal Choice Today

A stainless steel heat exchanger pipe excels in durability, thermal stability, corrosion resistance, mechanical performance, and versatility. Its material characteristics deliver long-term value across HVAC, chemical, energy, marine, and food-processing industries. With growing emphasis on sustainability and operational efficiency, stainless steel continues to outperform alternative materials and remains a critical component in modern thermal engineering.

In addition, leading suppliers such as Shuangsen focus on high-precision production, consistent quality control, and advanced welding and annealing technologies to ensure reliable performance under demanding industrial environments. For customized specifications, application guidance, or bulk procurement needs, contact us for detailed technical support and professional solutions tailored to your project.