What Makes Sheet Metal Enclosures the Reliable Choice for Modern Industrial Applications?

2025-10-10

A Sheet Metal Enclosure is more than just a protective box—it is a structural safeguard designed to house and protect electronic, electrical, or mechanical components. In today’s industrial world, where systems are becoming increasingly compact and high-performing, the importance of reliable enclosures has never been greater. These enclosures ensure that delicate components are shielded from dust, moisture, electromagnetic interference, and mechanical damage.

Sheet metal, often made from steel, stainless steel, or aluminum, is the preferred material because of its durability, conductivity, and formability. Unlike plastic or composite enclosures, sheet metal offers higher strength-to-weight ratios and superior thermal management, making it ideal for harsh industrial environments, data centers, and telecommunication applications.

The significance of a well-designed sheet metal enclosure lies in its dual role—it provides both protection and aesthetic integration. For industries such as automation, telecommunications, and power distribution, enclosures are not optional; they are integral components ensuring operational safety and system longevity.

A quality Sheet Metal Enclosure ensures:

-

Corrosion resistance for outdoor and industrial use

-

Precision fitting for sensitive equipment

-

EMI/RFI shielding to prevent signal interference

-

Ease of maintenance and access for technicians

-

Compliance with safety and industrial standards

In short, the choice of a sheet metal enclosure can determine the long-term reliability and performance of the entire system it protects.

How Are Sheet Metal Enclosures Manufactured?

Understanding how a sheet metal enclosure is made provides insights into its precision and performance. Manufacturing involves multiple stages—each focused on accuracy, consistency, and durability.

The typical fabrication process includes:

| Stage | Process Description | Purpose |

|---|---|---|

| 1. Material Selection | Choosing steel, stainless steel, or aluminum based on strength and corrosion requirements. | Ensures mechanical and environmental performance. |

| 2. Laser Cutting / Punching | Sheets are cut into precise dimensions using CNC or fiber laser machines. | Guarantees clean edges and exact tolerances. |

| 3. Bending and Forming | The sheet is bent using press brakes to create the enclosure’s structure. | Achieves the required angles and rigidity. |

| 4. Welding / Fastening | Joints are welded or riveted for structural integrity. | Ensures enclosure durability and stability. |

| 5. Surface Treatment | Powder coating, galvanization, or anodizing is applied. | Enhances corrosion resistance and visual appeal. |

| 6. Assembly and Quality Testing | Components such as hinges, locks, or seals are installed and tested. | Confirms function, protection, and safety. |

Each of these steps contributes to producing enclosures that are both mechanically robust and visually refined. Advanced CNC fabrication and automated inspection technologies have made it possible to achieve tolerances within ±0.1 mm, a critical factor for tight-fitting electronic assemblies.

Manufacturers can also offer custom enclosures tailored to specific requirements—whether it’s unique dimensions, IP-rated sealing, or integration of cable management systems. These features are particularly important for industries operating in demanding environments like oil & gas, renewable energy, or military communications.

Why Choose a Sheet Metal Enclosure Over Other Materials?

When evaluating enclosure options, many engineers compare sheet metal, plastic, and composite materials. Each has its advantages, but sheet metal stands out for industrial-grade applications due to its balance of mechanical strength, thermal performance, and longevity.

Key Advantages of Sheet Metal Enclosures:

-

Superior Durability:

Sheet metal resists deformation and mechanical impacts, making it suitable for heavy-duty or outdoor applications. -

Thermal Management:

Metal’s natural heat conductivity allows better dissipation of heat from electronic components, preventing overheating and extending equipment life. -

Enhanced Shielding:

Sheet metal enclosures provide excellent EMI/RFI shielding, ensuring stable performance of sensitive electronics in industrial environments. -

Customizability:

They can be easily customized with precision holes, cutouts, and finishes to meet unique requirements—perfect for OEM equipment. -

Eco-Friendliness:

Most metals used in enclosures are recyclable, aligning with sustainable manufacturing practices and green compliance. -

Aesthetic Appeal:

With professional finishes like brushed stainless steel or matte powder coating, these enclosures maintain a clean, professional look even under rugged use.

Common Applications:

-

Industrial control cabinets

-

Server and network racks

-

Power distribution boxes

-

Telecom base station enclosures

-

HVAC and automation panels

-

Medical equipment housings

Technical Parameters Example:

| Parameter | Specification Range |

|---|---|

| Material | Cold-rolled steel, Stainless steel (304/316), Aluminum |

| Thickness | 0.8 – 3.0 mm |

| Protection Level | Up to IP66 |

| Surface Treatment | Powder coating, Zinc plating, Galvanized, Anodized |

| Operating Temperature | -40°C to +80°C |

| Optional Features | Mounting brackets, ventilation holes, cable glands, locks |

This combination of robustness, versatility, and precision makes sheet metal enclosures the go-to solution for industries that demand uncompromising quality.

How to Choose the Right Sheet Metal Enclosure for Your Project?

Selecting the right sheet metal enclosure depends on several engineering and environmental factors. Making the right choice can prevent costly downtime, equipment failure, or safety hazards.

Here’s a step-by-step guide to making the best choice:

-

Define Your Application Environment:

Identify if the enclosure will be used indoors, outdoors, or in corrosive environments. Stainless steel or aluminum is recommended for outdoor and marine settings. -

Assess Protection Requirements:

Choose enclosures with IP ratings (e.g., IP54, IP65, IP66) based on the need for dust and water resistance. -

Check Dimensional Compatibility:

Ensure the enclosure size fits your equipment, with enough clearance for ventilation and cable access. -

Consider Thermal and Electrical Factors:

For heat-sensitive components, select enclosures with thermal management options like vents or heat sinks. -

Customization and Mounting:

Look for manufacturers that offer custom-cut holes, modular panels, or wall/floor mounting options for better integration. -

Evaluate Certification and Compliance:

For industrial or electronic applications, ensure the enclosure meets standards like NEMA, UL, or CE. -

Prioritize Service and After-Sales Support:

Partner with a manufacturer that provides technical guidance, design customization, and reliable after-sales service.

Frequently Asked Questions (FAQs)

Q1: What materials are most commonly used for sheet metal enclosures?

A1: The most common materials are cold-rolled steel, stainless steel (grades 304 and 316), and aluminum. Each has unique advantages: cold-rolled steel offers cost efficiency, stainless steel provides superior corrosion resistance, and aluminum offers lightweight strength.

Q2: How can I ensure my sheet metal enclosure is weatherproof?

A2: To achieve weatherproofing, select an enclosure with a high IP rating (IP65 or higher), use gasket-sealed doors, and opt for powder-coated or anodized finishes. These features prevent water ingress and protect the metal surface from oxidation.

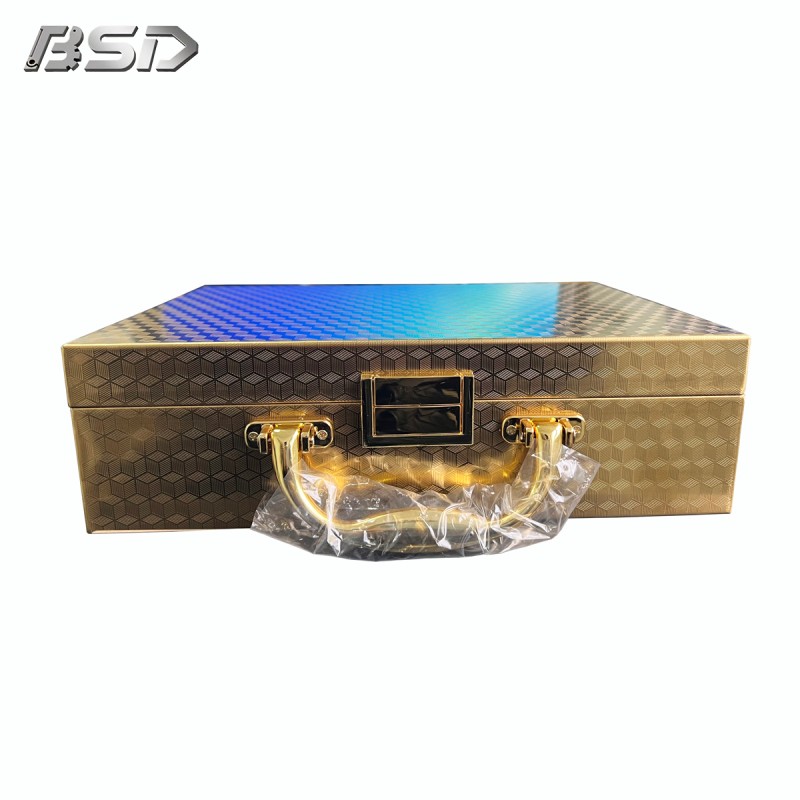

Why BSD Sheet Metal Enclosures Are Trusted Worldwide

Sheet metal enclosures play an essential role in protecting modern industrial systems. From safeguarding sensitive electronics to enabling efficient power management, their contribution to reliability, safety, and performance cannot be overstated. The combination of advanced fabrication techniques, premium materials, and precise engineering ensures these enclosures stand the test of time.

At BSD, we specialize in designing and manufacturing high-quality Sheet Metal Enclosures that meet international standards and exceed customer expectations. Our solutions cover a wide range of industrial applications, from automation systems to renewable energy equipment. Every enclosure is crafted with precision, ensuring maximum protection, durability, and aesthetic appeal.

If you’re looking for a customized sheet metal enclosure tailored to your specific needs, contact BSD today. Our engineering team is ready to support your project from design to production, ensuring your equipment is protected by the best enclosure solution available.

Contact us now to discuss your project specifications and get a quote tailored to your application.