What Makes Rectangular Tubes the Strong Backbone of Modern Construction and Manufacturing?

2025-11-04

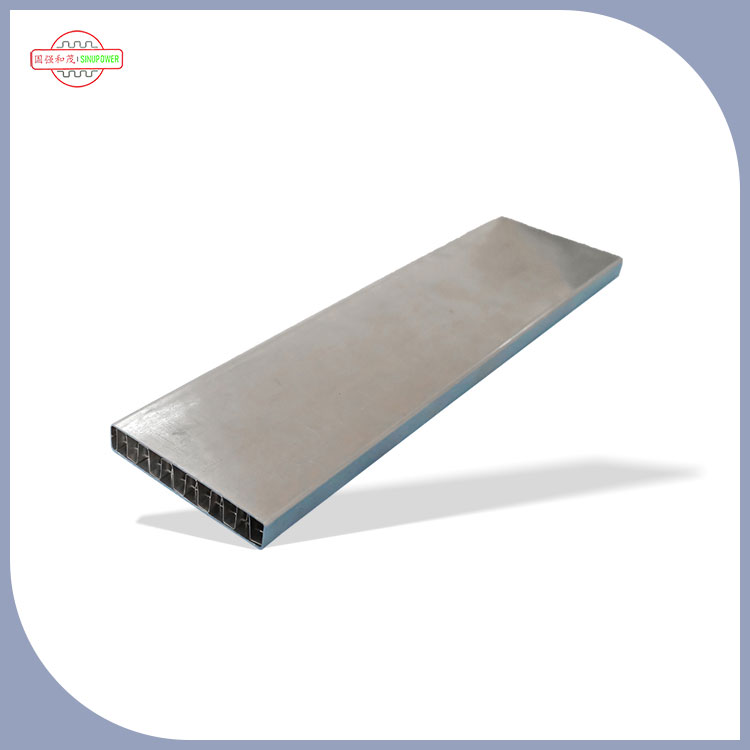

Rectangular tubes, often known as rectangular hollow sections (RHS), are a key component in modern engineering, architecture, and industrial manufacturing. They are characterized by their flat surfaces and uniform geometry, providing a perfect balance between strength, versatility, and weight efficiency. Whether used in structural frameworks, machinery fabrication, or automotive applications, rectangular tubes deliver superior performance due to their consistent wall thickness and high load-bearing capability.

In the construction sector, rectangular tubes are used to create reliable frameworks, support beams, bridges, and architectural facades. Their rectangular shape allows for easy welding, cutting, and integration into complex structures. The combination of mechanical stability and aesthetic simplicity makes them one of the most sought-after materials in the global steel and aluminum markets.

Beyond their physical properties, the growing popularity of rectangular tubes also reflects the industry’s shift toward sustainability and modular construction. Their efficient use of material means less waste, lower carbon footprint, and longer service life—all critical factors in green building design and sustainable infrastructure.

To better understand the technical precision of these tubes, consider the following general specification table commonly used in industrial applications:

| Specification | Description |

|---|---|

| Shape | Rectangular (Hollow Section) |

| Material Options | Carbon Steel, Stainless Steel, Aluminum, Galvanized Steel |

| Surface Finish | Mill Finish, Polished, Powder-Coated, Hot-Dip Galvanized |

| Standard Sizes | 20x10 mm to 400x200 mm |

| Wall Thickness Range | 1.0 mm – 20 mm |

| Tensile Strength | 350–700 MPa (depending on material) |

| Manufacturing Standards | ASTM A500, EN10219, JIS G3466, GB/T6728 |

| Applications | Construction, Automotive, Machinery, Furniture, Energy, Shipbuilding |

Rectangular tubes, with these detailed specifications, meet a wide range of industry needs—from light framing to heavy structural use. Their uniform geometry provides exceptional strength-to-weight ratios, ensuring both safety and cost-efficiency in engineering design.

Why Are Rectangular Tubes Preferred Over Other Shapes?

When comparing rectangular tubes to circular or square profiles, the reason for their preference becomes clear through three key performance dimensions: load distribution, surface adaptability, and space utilization.

1. Structural Efficiency:

Rectangular tubes provide better directional strength, especially in bending and compression. Their flat surfaces distribute load evenly, making them ideal for beams, columns, and platforms where one direction bears more stress than another.

2. Design Flexibility:

The rectangular profile allows easy integration with flat surfaces and right-angled joints, which are common in industrial and architectural designs. This makes them more practical than circular tubes when joining to plates, angles, or other rectangular components.

3. Cost and Material Optimization:

Because of their geometric uniformity, rectangular tubes require less reinforcement. They offer similar load resistance as circular tubes but consume less material, leading to cost savings in both manufacturing and assembly.

4. Corrosion and Surface Protection:

With surface finishes such as galvanization, powder coating, or polishing, rectangular tubes maintain excellent corrosion resistance even in harsh environments like coastal regions or chemical plants.

5. Sustainability:

Modern rectangular tubes are increasingly produced using recycled materials and low-carbon processes. The ease of cutting, welding, and reusing them also supports the global shift toward sustainable building practices.

In industrial applications, rectangular tubes are often chosen over other hollow sections because they simplify fabrication and reduce the need for custom fixtures. This makes them a preferred material in smart infrastructure and next-generation construction projects that demand precision, efficiency, and durability.

How Are Rectangular Tubes Shaping the Future of Construction and Engineering?

The global demand for rectangular tubes continues to rise, driven by technological innovation and sustainable development goals. From modular housing to renewable energy systems, their adaptability plays a crucial role in reshaping how industries design and build.

1. Smart Construction and Prefabrication:

In modern building systems, prefabricated steel structures are assembled off-site to reduce time and cost. Rectangular tubes are the backbone of these modular units, providing lightweight yet strong frameworks that can be transported and installed with minimal labor.

2. Automation and Robotics Manufacturing:

Rectangular tubes are increasingly used in robotic arms, automated assembly lines, and industrial equipment frames. Their flat surfaces allow for accurate mounting and alignment, supporting precision-based operations in advanced manufacturing.

3. Green and Sustainable Architecture:

Architects now choose rectangular tubes for their clean lines, recyclable materials, and ability to support solar panels, wind turbines, and eco-friendly facades. Their high durability ensures a long service life, reducing the frequency of replacement and material waste.

4. Infrastructure and Transportation:

In bridges, pipelines, railings, and vehicle frames, rectangular tubes enhance both strength and safety. In automotive design, aluminum rectangular tubes are favored for lightweight performance and fuel efficiency.

5. Technological Advancements in Material Science:

With the development of high-strength alloys and nano-coating technologies, the next generation of rectangular tubes will feature even higher resistance to fatigue, heat, and corrosion. These innovations open the door to aerospace and offshore applications, where reliability under extreme conditions is critical.

Common Questions About Rectangular Tubes

Q1: What factors should be considered when selecting rectangular tubes for a project?

A: When choosing rectangular tubes, several parameters determine their performance: material composition, wall thickness, surface treatment, and dimensional tolerance. For structural applications, steel tubes (ASTM A500 or EN10219 standards) are recommended for their high load capacity. For lightweight designs, aluminum tubes are preferred. The surface finish—whether galvanized, polished, or coated—depends on exposure to environmental elements. Always ensure compliance with local building codes and test standards for safety and durability.

Q2: How can rectangular tubes be maintained for long-term use?

A: Proper maintenance extends the service life of rectangular tubes significantly. Regular inspection for corrosion, repainting or recoating when necessary, and ensuring drainage in outdoor installations prevent rust and degradation. For stainless and aluminum types, periodic cleaning using non-abrasive solutions keeps the surface intact. In industrial environments, applying protective coatings or anti-corrosive treatments further enhances durability and performance.

Future Trends and Market Outlook

The future of rectangular tubes lies in innovation, sustainability, and digital integration. As the construction and manufacturing industries move toward automation and smart design, the demand for precision-engineered hollow sections will continue to increase. Digital design tools now allow engineers to simulate stress, load, and fatigue on rectangular tubes before production, ensuring optimal safety and efficiency.

Sustainability will also play a defining role. With the rise of green certifications like LEED and BREEAM, materials with high recyclability and low carbon footprints are becoming the industry standard. Rectangular tubes made from recycled steel and aluminum align perfectly with these goals.

Furthermore, hybrid materials—such as fiber-reinforced metal tubes—are expected to emerge, combining the strength of metals with the flexibility of composites. This advancement will open new possibilities in transportation, aerospace, and renewable energy construction.

Rectangular tubes stand at the core of modern industrial and architectural design. Their unmatched balance of strength, versatility, and sustainability has made them indispensable across a wide range of applications—from skyscrapers to smart factories. As material technology continues to evolve, rectangular tubes will play an even greater role in shaping safer, greener, and more efficient infrastructure around the world.

With decades of expertise in precision manufacturing, Sinupower is committed to delivering high-quality rectangular tubes that meet international standards and the diverse needs of global industries. For more information or to explore custom solutions, contact us today to discuss how our advanced tubular products can enhance your next project.