What Makes Metal Forged Parts the Foundation of Modern Manufacturing?

2025-11-06

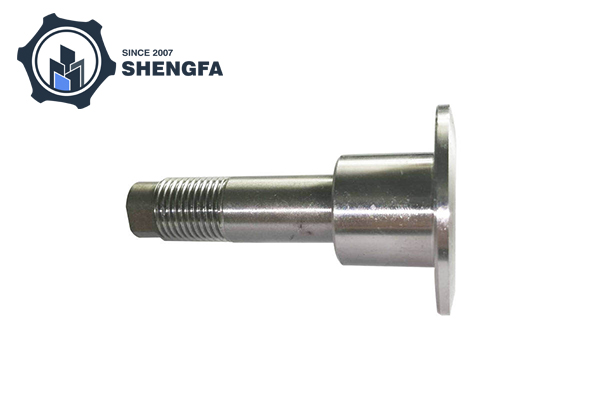

Metal Forgedrt Parts are precision-engineered components created by shaping metal under high pressure and temperature to achieve superior strength, durability, and performance. Unlike cast or machined parts, forged parts are produced through controlled deformation, aligning the metal’s grain structure to enhance its mechanical properties. This process ensures excellent toughness, fatigue resistance, and reliability in critical applications such as automotive, aerospace, construction, energy, and heavy machinery.

The primary objective of forging is to create components that can withstand high stress, temperature fluctuations, and repeated impact without deforming or breaking. As industries demand stronger and more efficient materials, Metal Forged Parts have become indispensable due to their unmatched structural integrity and long service life.

Forging can be classified into open-die forging, closed-die forging, and cold forging, depending on the temperature and method used. Each technique offers unique advantages in terms of precision, production volume, and material flexibility.

Product Parameters of Metal Forged Parts

| Parameter | Description |

|---|---|

| Material Options | Carbon steel, alloy steel, stainless steel, aluminum, brass, titanium |

| Forging Methods | Hot forging, cold forging, open-die forging, closed-die forging |

| Surface Treatment | Polishing, sandblasting, heat treatment, coating |

| Tolerances | ±0.01 mm to ±0.05 mm depending on process |

| Applications | Automotive components, hydraulic fittings, construction hardware, gears, shafts, flanges |

| Strength Level | Up to 1,200 MPa (depending on material) |

| Temperature Resistance | -50°C to +800°C |

| Production Capacity | Customizable from small batches to large-scale production |

These parameters define the performance and precision of Metal Forged Parts in diverse industrial contexts. Manufacturers prefer forging for its ability to maintain consistency in quality, dimensional accuracy, and grain alignment, leading to parts that outperform alternatives made from casting or machining.

Why Are Metal Forged Parts Preferred Over Casting and Machining Processes?

The superiority of Metal Forged Parts lies in the metallurgical and mechanical advantages they offer. The forging process enhances the internal grain structure, resulting in components with greater strength and reliability. In contrast, cast parts are prone to internal voids or porosity, while machined components can suffer from weak points due to material removal.

Key Advantages of Metal Forged Parts:

-

Enhanced Strength and Toughness – Forging refines the grain flow, ensuring maximum mechanical strength and resistance to fatigue and impact.

-

Improved Durability – Forged components endure demanding environments and repetitive loading conditions without cracking or deformation.

-

Dimensional Precision – With modern CNC forging equipment, parts can achieve tight tolerances suitable for high-precision applications.

-

Material Efficiency – Forging reduces material waste compared to machining, making it a cost-effective and sustainable production method.

-

Superior Surface Quality – After finishing and heat treatment, forged surfaces achieve smooth finishes and enhanced corrosion resistance.

-

Wide Range of Materials – Forging can be performed on various metals, including carbon steel, stainless steel, aluminum, and titanium, giving manufacturers flexibility in design and function.

In industries such as automotive and aerospace, forged parts are used in components like crankshafts, connecting rods, and landing gear due to their ability to handle stress and vibration. In construction and mining, forged tools and fittings ensure reliability under extreme working conditions.

Forged components also contribute to energy efficiency—lighter, stronger parts reduce mechanical stress and fuel consumption in transport machinery. With sustainability becoming a global priority, the ability to produce high-strength parts with less material waste makes forging a critical process for future manufacturing.

How Are Metal Forged Parts Manufactured and What Innovations Are Shaping Their Future?

The production of Metal Forged Parts involves a series of precise steps to ensure quality and performance. Each stage is carefully controlled to maintain consistent mechanical strength, shape accuracy, and metallurgical integrity.

Manufacturing Process Overview

-

Material Selection – Choose appropriate alloy or metal based on strength, corrosion resistance, and thermal performance requirements.

-

Heating – Metal billets are heated to specific forging temperatures to improve malleability without compromising composition.

-

Forging Process – Using hydraulic presses or hammers, the metal is shaped into the desired form while controlling grain flow.

-

Trimming and Machining – Excess material is removed to achieve the exact dimensions required by the design.

-

Heat Treatment – Forged parts are hardened, tempered, or annealed to enhance strength and toughness.

-

Surface Finishing – Processes such as polishing, coating, or shot blasting improve appearance and corrosion resistance.

-

Quality Inspection – Each part undergoes rigorous dimensional and mechanical testing to ensure compliance with industry standards.

Technological Trends in Metal Forging

-

Automation and Smart Forging Systems – Integration of robotics and digital monitoring ensures consistent temperature control and deformation accuracy.

-

Advanced Alloys Development – New metal alloys improve heat resistance, corrosion protection, and fatigue life.

-

Closed-Loop Forging Control – Sensors and feedback systems adjust force and temperature in real-time to enhance precision.

-

Sustainable Manufacturing – Modern forging methods reduce waste, energy consumption, and carbon footprint.

-

Near-Net-Shape Forging – Innovative dies and high-pressure systems create parts that require minimal post-processing.

As industries transition toward high-performance and lightweight materials, the role of Metal Forged Parts will continue to grow. Emerging sectors like renewable energy, electric vehicles, and aerospace propulsion are increasingly relying on forged components for their safety and reliability.

What Are the Future Prospects and Common Questions About Metal Forged Parts?

The global market for Metal Forged Parts is expanding rapidly due to technological advancements and increased demand for durable industrial components. The future of forging technology lies in precision automation, AI-assisted process monitoring, and eco-friendly production systems that minimize energy usage. Manufacturers are investing in digital twins and simulation tools to predict material flow, improve die design, and reduce trial-and-error costs.

Moreover, the shift toward sustainability and lightweight engineering has made aluminum and titanium forging more popular in modern applications. These materials provide excellent strength-to-weight ratios and are essential for the automotive and aerospace industries striving for better efficiency and lower emissions.

Common FAQs About Metal Forged Parts

Q1: What industries benefit the most from Metal Forged Parts?

A1: Metal Forged Parts are widely used in automotive, aerospace, oil and gas, construction, agriculture, and heavy machinery sectors. Their ability to handle extreme stress and temperature makes them ideal for critical components such as gears, shafts, couplings, and flanges.

Q2: How does forging improve the mechanical properties of metal?

A2: Forging refines the grain structure of metal through deformation under heat and pressure. This process aligns the internal grain flow with the part’s shape, reducing internal voids and improving tensile strength, ductility, and impact resistance. The result is a more reliable component capable of performing in harsh operating environments.

Looking ahead, Metal Forged Parts will continue to evolve with digital manufacturing, sustainable materials, and precision engineering. The integration of automated control systems and predictive modeling will enhance quality while reducing production time and waste. This evolution ensures that forged parts remain at the core of industrial development for decades to come.

Metal Forged Parts play a fundamental role in the world’s manufacturing landscape. Their superior strength, durability, and adaptability make them the foundation for countless industrial applications, from transportation and construction to aerospace and energy production. With continuous advancements in forging technology and materials science, the future points toward even stronger, lighter, and more sustainable forged components.

Ningbo Shengfa Hardware has established itself as a trusted manufacturer of high-quality Metal Forged Parts, delivering precision-engineered components tailored to meet diverse industry needs. With expertise in advanced forging techniques and a commitment to innovation, the company ensures exceptional performance and reliability across every product line.

Contact us today to learn more about customized forging solutions and how Ningbo Shengfa Hardware can support your industrial projects with premium-quality forged components built to last.