What Makes Battery Cooling Plates So Important Today?

2025-10-10

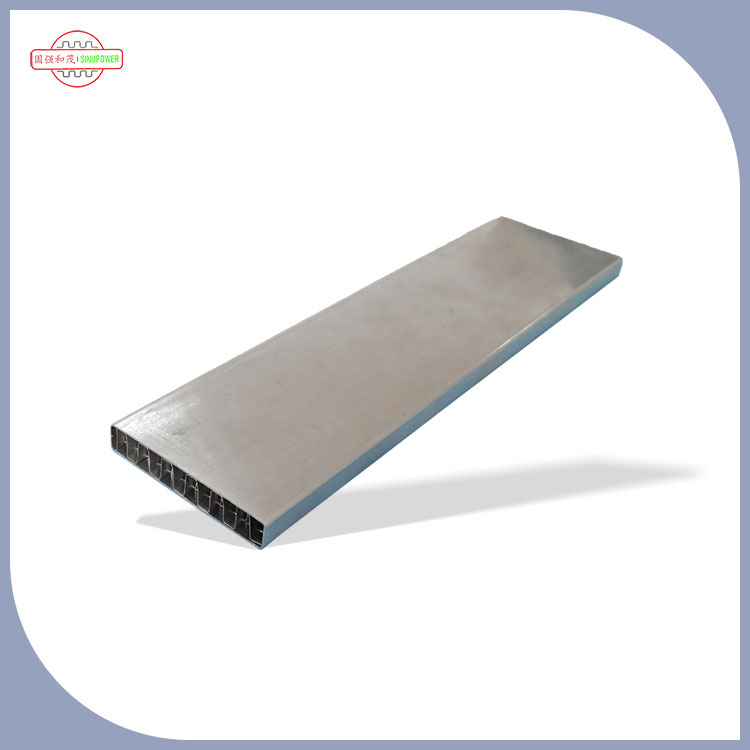

In an era where electric vehicles (EVs), renewable energy storage, and high-performance electronics are rapidly evolving, Battery Cooling Plates have become an indispensable component. These plates are designed to maintain optimal temperature levels in lithium-ion battery systems, ensuring stability, safety, and long service life.

I often get asked — why focus so much on cooling systems when the battery itself is the heart of the product? The answer lies in efficiency and longevity. Without proper thermal management, even the most advanced battery systems face risks of overheating, capacity degradation, or even failure. That's why Sinupower Heat Transfer Tubes Changshu Ltd. specializes in designing and manufacturing high-performance Battery Cooling Plates that deliver consistent temperature control under various operating conditions.

How Do Battery Cooling Plates Work?

The working principle behind Battery Cooling Plates is simple yet highly effective. They use liquid or air channels embedded within the plate to absorb and transfer heat away from battery cells. The coolant — usually a mixture of water and glycol — flows through these channels, maintaining uniform temperature distribution across the battery pack.

This process reduces thermal gradients, preventing localized overheating and optimizing energy efficiency. In EV applications, efficient cooling not only enhances driving range but also extends the battery's overall lifespan.

Why Choose Sinupower Battery Cooling Plates?

At Sinupower Heat Transfer Tubes Changshu Ltd., we have over a decade of expertise in heat transfer and cooling system solutions. Our Battery Cooling Plates are engineered with high-precision aluminum or stainless-steel channels to provide maximum heat dissipation and minimal weight.

We use advanced welding and extrusion technologies to ensure tight sealing, uniform flow resistance, and corrosion resistance — all critical factors in maintaining system reliability. Our cooling plates are ideal for electric vehicles, hybrid systems, energy storage units, and industrial power equipment.

Product Specifications of Sinupower Battery Cooling Plates

Below is a general overview of the technical parameters of our Battery Cooling Plates:

| Parameter | Specification |

|---|---|

| Material Options | Aluminum Alloy / Stainless Steel / Copper |

| Cooling Medium | Water-Glycol Mixture / Dielectric Fluid |

| Plate Thickness | 2 mm – 10 mm |

| Channel Type | Serpentine / Parallel / Customized |

| Operating Temperature Range | -40°C to +120°C |

| Maximum Pressure | Up to 2.5 MPa |

| Surface Treatment | Anodized / Anti-Corrosion Coating |

| Manufacturing Process | Brazing / Friction Stir Welding / CNC Machining |

| Customization | Available for EV, ESS, and Industrial Applications |

Each plate is carefully tested for leakage, pressure endurance, and thermal conductivity. This guarantees that our Battery Cooling Plates deliver stable performance under various environmental conditions.

What Are the Key Advantages of Battery Cooling Plates?

-

Enhanced Battery Life – By maintaining ideal operating temperatures, the plates prevent thermal stress and extend battery lifespan.

-

Improved Safety – Overheating is a major cause of thermal runaway. Cooling plates reduce this risk significantly.

-

Higher Efficiency – Consistent temperature control ensures optimal energy conversion rates.

-

Lightweight Design – Aluminum construction minimizes added mass, perfect for EV applications.

-

Flexible Customization – Shapes, channel layouts, and inlet/outlet configurations can be tailored for any battery module.

-

Low Maintenance – Our design ensures long-term performance with minimal service requirements.

Where Are Battery Cooling Plates Commonly Used?

Battery cooling technology has become a foundation for multiple modern applications:

-

Electric and Hybrid Vehicles (EVs & HEVs): To keep traction batteries within safe operating limits.

-

Energy Storage Systems (ESS): For grid-scale power storage where stable performance is crucial.

-

Aerospace & Marine Systems: To handle extreme thermal environments.

-

Telecommunication Equipment: To cool high-density battery packs in base stations.

-

Industrial Power Units: Ensuring reliable performance in automation and robotics systems.

At Sinupower Heat Transfer Tubes Changshu Ltd., we provide tailored cooling solutions for all these applications, combining high performance with cost efficiency.

How Does the Design of Battery Cooling Plates Affect Performance?

The geometry of the internal channels — whether parallel or serpentine — has a major influence on temperature uniformity and pressure drop. Parallel channels ensure uniform cooling but require precise flow balancing. Serpentine channels, on the other hand, are simpler and cost-effective but may create slight temperature gradients.

Our engineering team uses computational fluid dynamics (CFD) simulations to optimize channel geometry, ensuring superior thermal management and minimal flow resistance. This allows clients to achieve maximum efficiency with minimal energy loss.

What Materials Are Best for Battery Cooling Plates?

Selecting the right material depends on the system's cooling medium, thermal load, and design constraints.

-

Aluminum Alloy: Lightweight, excellent thermal conductivity, corrosion-resistant.

-

Copper: Superior heat transfer but heavier and costlier.

-

Stainless Steel: Best for high-pressure or chemically aggressive environments.

Our team helps clients choose the most suitable material to match their specific application and cost targets.

Frequently Asked Questions (FAQ) About Battery Cooling Plates

Q1: What exactly are Battery Cooling Plates used for?

A1: Battery Cooling Plates are designed to regulate the temperature of battery packs in electric vehicles and energy storage systems. By removing excess heat, they prevent thermal runaway, enhance safety, and extend battery life.

Q2: How do Battery Cooling Plates improve battery performance?

A2: By maintaining uniform cell temperature, cooling plates prevent uneven charging or discharging. This improves efficiency, increases usable capacity, and enhances the long-term stability of the battery pack.

Q3: Are Sinupower Battery Cooling Plates customizable?

A3: Yes. Sinupower Heat Transfer Tubes Changshu Ltd. offers complete customization, including size, channel pattern, inlet/outlet configuration, and materials. We can design plates tailored to your specific module structure and cooling requirements.

Q4: What maintenance do Battery Cooling Plates require?

A4: Minimal maintenance is needed. Routine inspections for coolant quality and possible leaks are sufficient. Our plates are designed with high sealing integrity, ensuring long-term operation without performance degradation.

Contact Us

We understand that reliability, efficiency, and safety are your top priorities. At Sinupower Heat Transfer Tubes Changshu Ltd., we combine advanced manufacturing technologies with a deep understanding of heat transfer dynamics. Our R&D and production teams deliver customized solutions that meet international quality standards and environmental regulations.

From prototyping to mass production, we work closely with clients to optimize cost, weight, and performance. Whether you are designing EV battery packs or industrial energy systems, we have the expertise to support your projects with durable and high-efficiency cooling solutions.

If you're looking for a trusted partner to provide efficient Battery Cooling Plates for your energy system, don't hesitate to reach out to Sinupower Heat Transfer Tubes Changshu Ltd.