What Makes a Modern Water Treatment System the Key to Clean and Sustainable Water Solutions?

2025-11-03

Water is the foundation of life, yet access to clean and safe water is still one of the world’s greatest challenges. A water treatment system plays a critical role in ensuring that water from various sources—such as rivers, lakes, wells, or municipal supplies—is purified and made safe for human consumption, industrial applications, and agricultural use. The core purpose of such systems is to remove contaminants, neutralize harmful chemicals, and restore the natural balance of water for sustainable use.

The demand for efficient water treatment systems continues to rise due to increasing population density, industrial expansion, and environmental pollution. Businesses, municipalities, and households all seek reliable solutions that guarantee purity, consistency, and compliance with international water quality standards. In this context, advanced treatment technologies—such as reverse osmosis (RO), ultrafiltration (UF), and UV sterilization—have become central to the development of modern systems that ensure both safety and sustainability.

What Are the Core Components and Technical Parameters of a Water Treatment System?

A professional-grade water treatment system is typically composed of several interdependent modules, each designed for a specific function within the purification process. Below is a structured overview of the main components and parameters commonly found in a high-quality system:

| Component | Function | Technical Parameters |

|---|---|---|

| Pre-Filtration Unit | Removes large particles, sediments, and suspended solids | Micron rating: 5–20 µm; Flow rate: 1–20 m³/h |

| Activated Carbon Filter | Adsorbs chlorine, organic compounds, and odor | Carbon type: Coconut shell; Iodine value: ≥1000 mg/g |

| Water Softener | Reduces hardness by removing calcium and magnesium ions | Resin volume: 25–75 L; Regeneration cycle: Automatic |

| Reverse Osmosis (RO) Unit | Eliminates dissolved salts, heavy metals, and pathogens | Membrane type: TFC; Salt rejection: 98–99%; Pressure: 150 psi |

| UV Sterilizer | Kills bacteria and viruses without chemicals | Wavelength: 254 nm; Lamp life: 9000 hours |

| Post-Filtration Unit | Enhances taste and final water polish | Filter type: Inline carbon; Flow capacity: 1000 L/h |

| Control System (PLC) | Automates process, monitors performance, and safety | Interface: Touchscreen; Communication: RS485/Modbus |

These parameters may vary depending on system capacity, application type, and installation environment. Industrial-scale systems often feature additional modules such as chemical dosing units, pH regulators, and automatic backwash filters.

By integrating these modules effectively, the system ensures a continuous supply of purified water with stable quality, low maintenance, and optimized energy efficiency.

Why Are Water Treatment Systems Becoming Increasingly Important?

The importance of water treatment systems has grown significantly as water scarcity and pollution intensify. From industrial plants to residential buildings, clean water is a necessity—not a luxury. Several key factors explain why these systems are no longer optional:

1. Rising Contamination Levels

Urbanization and industrial growth have led to unprecedented water pollution levels. Heavy metals, pesticides, and microplastics are now frequently detected in natural water sources. A water treatment system provides a multi-layered defense against these contaminants, restoring water purity through physical, chemical, and biological processes.

2. Compliance with Environmental Regulations

Global environmental authorities—such as the U.S. Environmental Protection Agency (EPA) and the European Environment Agency (EEA)—enforce strict water quality regulations. Companies and municipalities must comply with these standards to ensure safety and sustainability. Modern treatment systems are designed to meet or exceed these requirements efficiently.

3. Public Health Protection

Unsafe water is a primary cause of disease outbreaks in many regions. A reliable water treatment system effectively eliminates bacteria, viruses, and protozoa, minimizing the risk of waterborne diseases like cholera and typhoid.

4. Industrial Efficiency

For industries such as pharmaceuticals, food and beverage, and electronics manufacturing, water purity directly affects product quality. Advanced filtration and purification technologies ensure process water meets the highest purity requirements, preventing corrosion, scaling, and contamination in production lines.

5. Sustainability and Cost Savings

Water recycling and reuse are now essential components of sustainable development. By integrating energy-efficient technologies and reusing treated wastewater, organizations can significantly reduce operational costs and environmental impact.

How Do Water Treatment Systems Work and What Technologies Drive Them?

The operation of a modern water treatment system involves several sequential processes, each designed to target specific impurities:

Step 1: Coarse Filtration

Water passes through a pre-filter that captures large particles like sand, rust, and silt. This step prevents clogging and prolongs the lifespan of downstream equipment.

Step 2: Activated Carbon Adsorption

Activated carbon removes organic compounds, chlorine, and odors. This stage improves water taste and prevents damage to sensitive filtration membranes in later stages.

Step 3: Ion Exchange or Softening

Water softeners replace hardness ions (Ca²⁺ and Mg²⁺) with sodium or hydrogen ions, reducing scaling and improving the performance of reverse osmosis membranes.

Step 4: Reverse Osmosis Filtration

RO membranes act as ultra-fine barriers that reject 98–99% of dissolved salts, heavy metals, and microorganisms. This is one of the most effective purification stages in any system.

Step 5: Ultraviolet (UV) Sterilization

In this chemical-free disinfection method, UV light destroys the DNA of bacteria and viruses, preventing reproduction and ensuring microbiological safety.

Step 6: Post-Treatment and Storage

Final polishing filters enhance taste and ensure the water meets drinking-quality standards. Treated water is then stored in a clean tank, ready for use or further distribution.

Modern systems also integrate PLC control panels with automatic sensors that monitor flow, pressure, and conductivity. This automation ensures consistent quality and reduces human error, making the system intelligent and user-friendly.

What Are the Future Trends in Water Treatment Technology?

The future of water treatment lies in smart, sustainable, and energy-efficient innovations. Emerging trends include:

-

AI and IoT Integration: Smart sensors and real-time monitoring systems allow predictive maintenance, remote diagnostics, and adaptive operation.

-

Membrane Advancements: Next-generation nanocomposite membranes offer higher rejection rates and longer service life.

-

Green Chemistry Solutions: Eco-friendly coagulants and biodegradable resins are replacing traditional chemical agents.

-

Zero-Liquid Discharge (ZLD): This technology minimizes wastewater generation, enabling total water recovery and minimal environmental impact.

-

Solar-Powered Treatment Systems: Renewable energy integration helps reduce operating costs and supports sustainability goals in remote or off-grid locations.

These advancements are reshaping how industries and communities view water—not just as a resource, but as a renewable asset that must be preserved through intelligent management and innovation.

Common Questions About Water Treatment Systems

Q1: How often should a water treatment system be maintained?

A: Maintenance frequency depends on water quality, usage, and system design. Generally, filters should be replaced every 6–12 months, RO membranes every 2–3 years, and UV lamps annually. Regular maintenance ensures optimal efficiency, extends equipment lifespan, and prevents bacterial buildup.

Q2: What factors determine the right water treatment system for a specific application?

A: Selection depends on factors such as feed water quality (TDS, hardness, pH), flow rate requirements, and end-use purposes (drinking, industrial, or process water). For instance, high-TDS industrial water may require multi-stage RO combined with deionization, while domestic systems may only need basic filtration and UV sterilization.

A Future Built on Clean Water

Clean and sustainable water is not just a necessity—it is a foundation for progress and health. Water treatment systems represent the technological and environmental bridge between demand and purity. They transform contaminated sources into usable water, ensuring the well-being of both humanity and the planet.

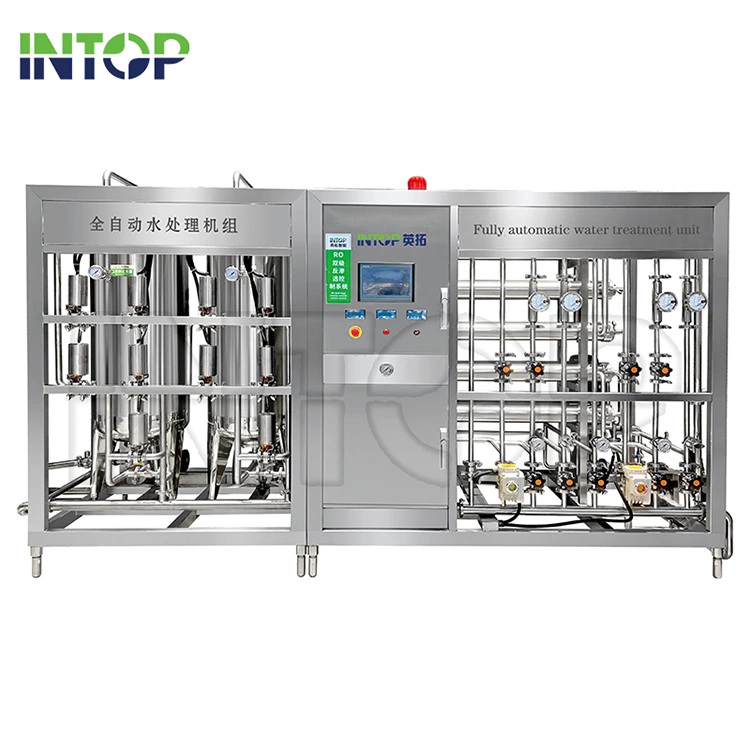

The INTOP Water Treatment System exemplifies this vision. With advanced purification technologies, intelligent control systems, and eco-efficient designs, INTOP continues to deliver reliable solutions tailored for diverse industries and communities worldwide. Each system is built with precision, quality, and sustainability at its core.

For professional consultation, system customization, or partnership inquiries, contact us to discover how INTOP can help build a cleaner, safer, and more sustainable water future.