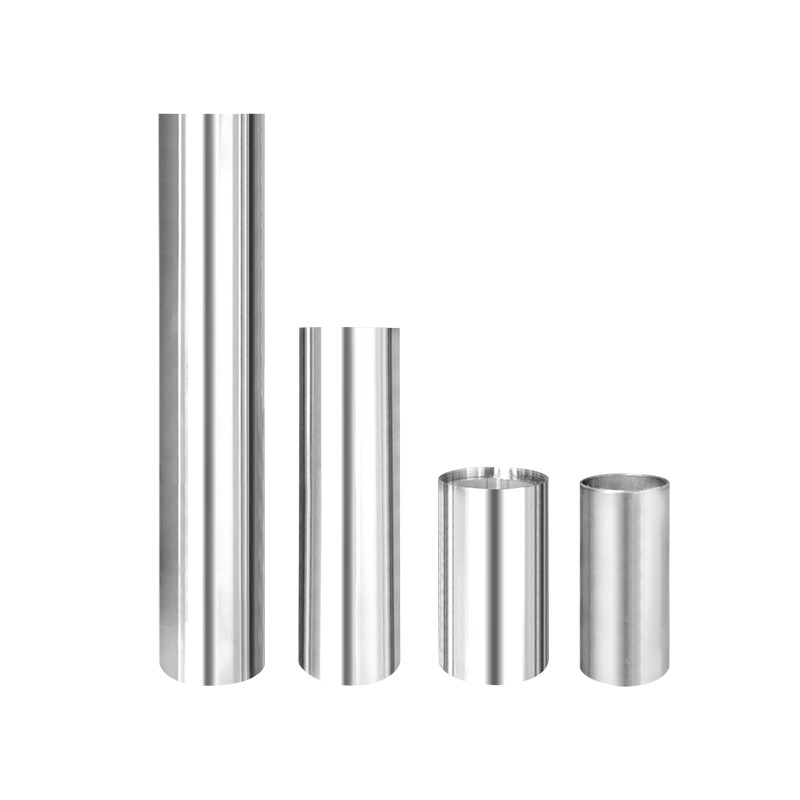

Stainless Steel Welded Pipe Applications and Advantages

2025-08-15

Stainless steel welded pipes have become essential components across multiple industries due to their superior durability, corrosion resistance, and cost-effectiveness. This guide explores HengDi's premium stainless steel welded pipe products, detailing their technical specifications, key advantages, industrial applications, and selection criteria to help you make informed purchasing decisions.

1. Product Specifications and Technical Data

HengDi manufactures stainless steel welded pipes that meet international ASTM, EN, and JIS standards:

Standard Product Line Specifications

| Grade | Outer Diameter (mm) | Wall Thickness (mm) | Length (m) | Surface Finish | Pressure Rating |

|---|---|---|---|---|---|

| 304/304L | 12.7-762 | 0.5-12.7 | 6-12 | BA/2B/No.4 | 100-3000 PSI |

| 316/316L | 15-610 | 0.8-12.7 | 6-12 | BA/2B/No.4 | 150-3500 PSI |

| 321 | 10-508 | 0.5-10 | 6-12 | Annealed | 200-4000 PSI |

| Duplex 2205 | 25-457 | 1.5-12 | 6-12 | Pickled | 300-5000 PSI |

Key Manufacturing Standards

✔ ASTM A312/A358: Standard specification for seamless/welded pipes

✔ EN 10217-7: Pressure purposes stainless steel pipes

✔ JIS G3459: Japanese industrial standard

✔ ISO 9001:2015 certified production

2. Advantages of Stainless Steel Welded Pipes

Material Benefits

-

Corrosion resistance: Withstands harsh chemicals and marine environments

-

High strength-to-weight ratio: Lighter than carbon steel alternatives

-

Hygienic properties: Ideal for food/pharmaceutical applications

-

Aesthetic appeal: Maintains appearance over time

Economic Advantages

✔ 30-50% cost savings vs. seamless pipes

✔ Faster production lead times (2-4 weeks)

✔ Lower maintenance requirements

✔ Longer service life (20+ years)

3. Industrial Applications

Major Usage Sectors

| Industry | Application | Recommended Grade |

|---|---|---|

| Oil & Gas | Pipeline systems | 316L/Duplex 2205 |

| Chemical Processing | Reactor piping | 316Ti/904L |

| Food & Beverage | Processing lines | 304/316 Mirror |

| Construction | Structural elements | 304/201 |

| Water Treatment | Desalination plants | Super Duplex |

Special Application Features

-

High-temperature service: Up to 800°C (1472°F)

-

Cryogenic applications: Down to -200°C (-328°F)

-

Sanitary tubing: Electropolished interior

-

Architectural uses: Decorative finishes available

4. Selection Guide and Quality Assurance

Choosing the Right Pipe

-

Material selection: Consider corrosive environment

-

Size requirements: Match flow capacity needs

-

Pressure rating: Verify system requirements

-

Surface finish: Based on application needs

HengDi Quality Control Process

-

Raw material inspection: Spectrometer analysis

-

Welding process: Automated TIG welding

-

Testing procedures: Hydrostatic, eddy current, X-ray

-

Final inspection: Dimensional verification

Why Choose HengDi Stainless Steel Welded Pipes?

✔ 15+ years specialized manufacturing experience

✔ Custom sizes and specifications available

✔ Complete certification documentation

✔ Competitive OEM pricing

✔ Global shipping capabilities

For product specifications or application consultation:

📧 Email: [email protected]

As HengDi's Technical Director with 20 years in pipe manufacturing, I guarantee our stainless steel welded pipes deliver unmatched performance for your most demanding applications. Contact our sales team today for personalized service.