Stainless steel pipes for power equipment manufacturing: Laying a solid foundation for the operation of the power system

2025-07-28

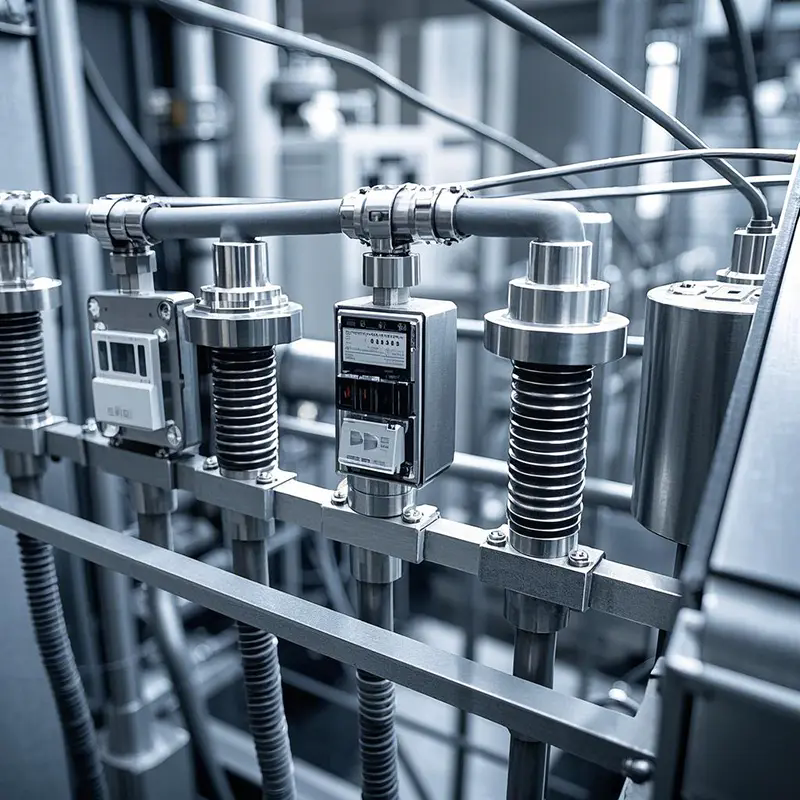

In the field of power equipment manufacturing, stainless steel pipes for power equipment manufacturing have become key components to ensure the stable operation of equipment due to their mechanical strength and weather resistance. It can adapt to the complex operating environment of the power system, resist adverse factors such as high temperature and corrosion, and provide reliable structural support and medium transportation channels for power transmission and conversion equipment.

Adaptation logic of material performance and power scenarios

The selection of materials for stainless steel pipes for power equipment manufacturing fully considers the special needs of the power system. The addition of high chromium-nickel alloy components enables it to have an antioxidant capacity far exceeding that of ordinary steel pipes, and can maintain structural stability in a long-term high-temperature operating environment, avoiding the thinning of the pipe wall thickness and the decrease in strength due to oxidation and rust. At the same time, its excellent mechanical strength can withstand the vibration and pressure generated during the operation of the equipment, ensuring that there will be no deformation or rupture under high-voltage and high-current working conditions, providing a basic guarantee for the safe operation of power equipment.

Safe extension of structural design

The structural design of this type of stainless steel pipe focuses on integration with power equipment. Precise dimensional tolerance control allows the pipeline to seamlessly connect with the equipment interface, reducing energy loss or medium leakage caused by connection gaps; the smooth treatment of the inner wall reduces the resistance during medium transportation and improves the operating efficiency of the cooling system and hydraulic system. In addition, some special-purpose pipelines also adopt a double-layer structure design. The insulation layer in the middle can effectively block heat transfer, protect other parts of the equipment from high temperature, and further enhance the operating safety of power equipment.

Cost advantage of the whole life cycle

From the perspective of long-term use, stainless steel pipes for power equipment manufacturing show significant cost advantages. Its weather resistance and corrosion resistance greatly extend the service life, reduce the frequency of pipeline replacement during equipment maintenance, and reduce production losses caused by downtime maintenance. At the same time, good weldability and plasticity make it easier to process during equipment installation and modification, can adapt to the structural requirements of different equipment, reduce the additional cost of customized processing, and provide support for power equipment manufacturers to achieve cost reduction and efficiency improvement throughout the life cycle.

ZHEJIANG SHUANGSEN METAL TECHNOLOGY CO., LTD. has demonstrated professional industry strength with its deep understanding of the properties of metal materials and technical accumulation. The company focuses on providing high-quality stainless steel pipe products for power equipment manufacturing. Through strict material screening and precision processing technology, it ensures that the products meet the stringent requirements of the power system in terms of strength, weather resistance and structural accuracy, helping power equipment to maintain stability and efficiency in complex operating environments, and providing reliable material support for the safe development of the power industry.