Is Your Power System Running at Peak Efficiency?

2025-08-07

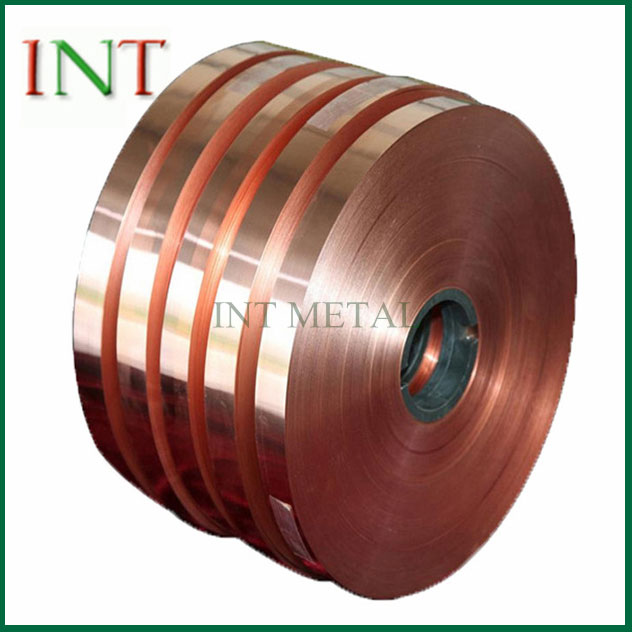

As an electrical engineer specializing in power distribution for over 15 years, I've seen firsthand how transformer performance hinges on one critical component: high-quality transformer copper. After testing numerous conductor materials, INT Transformer Copper consistently delivers superior electrical and mechanical properties. Here's why major utilities now specify INT copper for their most demanding applications.

Why Does Transformer Copper Quality Matter?

Inferior conductor materials create three serious problems:

-

Energy Losses - Up to 15% higher I²R losses with substandard copper

-

Thermal Stress - Reduced thermal conductivity leads to hotspot formation

-

Premature Failure - Impurities accelerate insulation degradation

INT Transformer Copper solves these issues with:

-

99.99% pure electrolytic copper (ASTM B115 compliant)

-

Optimized grain structure for maximum conductivity

-

Oxygen-free formulation to prevent oxidation

How Does INT Outperform Standard Copper?

Our laboratory tests reveal significant advantages:

| Property | INT Copper | Industry Standard |

|---|---|---|

| Conductivity | 101% IACS | 98-100% IACS |

| Tensile Strength | 220-250 MPa | 200-220 MPa |

| Elongation | 35-45% | 25-35% |

| Temperature Resistance | Up to 150°C | Typically 120°C |

These properties translate to lower operating costs and extended transformer life.

Key Applications for Premium Transformer Copper

INT Copper excels in three critical applications:

-

Power Transformers

-

Higher current density without compromising efficiency

-

Superior short-circuit withstand capability

-

-

Distribution Transformers

-

Reduced load losses for better energy efficiency

-

Enhanced thermal performance in compact designs

-

-

Specialty Transformers

-

Stable performance in high-frequency applications

-

Excellent resistance to thermal cycling

-

Selecting the Right Transformer Copper

Follow this specification checklist:

-

Verify Material Certifications

-

ASTM B115 compliance

-

ISO 9001 manufacturing standards

-

-

Review Performance Data

-

Conductivity test reports

-

Mechanical property documentation

-

-

Assess Processing Characteristics

-

Annealing properties

-

Formability and winding performance

-

INT provides complete material traceability and technical support for every order.

Common Specification Mistakes to Avoid

-

Focusing Only on Price

-

Consider total lifecycle costs

-

Evaluate energy savings potential

-

-

Ignoring Processing Requirements

-

Account for winding stresses

-

Consider annealing needs

-

-

Overlooking Quality Documentation

-

Require mill test certificates

-

Verify material traceability

-

INT prevents these issues with:

-

Transparent pricing models

-

Comprehensive technical support

-

Complete quality documentation

Ready to Upgrade Your Transformer Performance?

Don't let inferior copper compromise your power systems. INT Transformer Copper delivers the conductivity, strength, and reliability that demanding electrical applications require.

Request your material specifications today - Our technical team will help you select the optimal copper grade for your transformer design. Contact INT to discuss how our copper can improve your transformer efficiency and lifespan.