How to Select B-Tubes for Folded Radiators?

2025-12-23

Abstract: This article provides a comprehensive overview of B-Tubes for folded radiators, focusing on their specifications, industrial applications, and expert guidance for selection and maintenance. It addresses common questions, comparing usage scenarios, and offers insights into optimizing radiator performance with high-quality B-Tubes.

Table of Contents

1. Introduction to B-Tubes for Folded Radiators

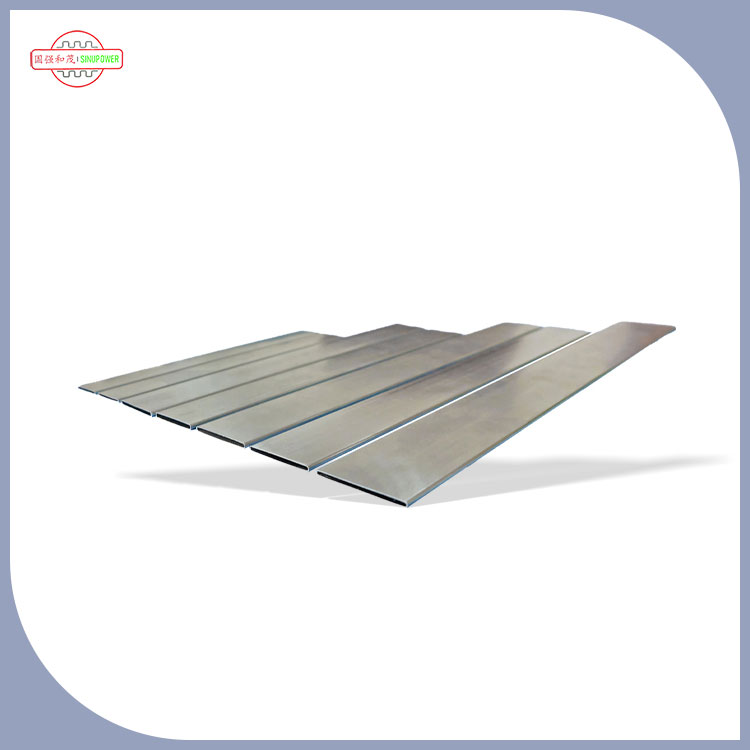

B-Tubes are a critical component in folded radiators, which are widely used in industrial heat exchange systems due to their compact structure and efficient thermal performance. These tubes are designed to facilitate fluid flow while maximizing surface area for heat dissipation. Selecting the correct B-Tubes directly impacts the radiator’s thermal efficiency, durability, and maintenance schedule.

This guide focuses on the technical parameters, industrial applications, and common operational considerations for B-Tubes, helping engineers, procurement managers, and maintenance professionals make informed decisions.

2. Key Specifications and Parameters

The performance of B-Tubes depends on a combination of material properties, dimensions, and manufacturing standards. Below is a summary of typical specifications for B-Tubes used in folded radiators:

| Specification | Typical Value | Description |

|---|---|---|

| Material | Stainless Steel / Copper / Aluminum | Resists corrosion and high-temperature stress |

| Tube Diameter | 15-30 mm | Outer diameter range compatible with standard folded radiator designs |

| Wall Thickness | 1.2-3.0 mm | Ensures mechanical strength and durability under pressure |

| Length | Varies by radiator model | Customized based on radiator configuration and folding pattern |

| Thermal Conductivity | 205-400 W/mK | Determines heat transfer efficiency |

| Operating Pressure | Up to 2.5 MPa | Suitable for industrial cooling systems |

Understanding these parameters allows precise selection of B-Tubes that meet performance and safety requirements for folded radiators in diverse industries.

3. Industrial Applications and Benefits

B-Tubes for folded radiators find applications in multiple sectors, including:

- Power plants and energy generation units

- Industrial HVAC systems

- Chemical processing plants

- Petrochemical and refinery equipment

- Heavy machinery cooling systems

These tubes provide uniform heat distribution, facilitate maintenance, and improve the overall efficiency of the radiator system. High-quality B-Tubes can significantly reduce downtime and energy loss, making them a critical investment for industrial operations.

4. Frequently Asked Questions about B-Tubes for Folded Radiators

Q1: How to determine the correct B-Tube size for a folded radiator?

A1: The correct B-Tube size is determined by the radiator's design, the fluid type, flow rate, and operating temperature. Manufacturers provide technical drawings and specifications to match the tube diameter and wall thickness to the radiator's heat transfer requirements. Using incorrect tube dimensions can reduce efficiency and compromise safety.

Q2: What materials are most suitable for B-Tubes in industrial applications?

A2: Stainless steel is widely preferred for its corrosion resistance and strength, especially in high-temperature or chemically aggressive environments. Copper and aluminum are chosen for applications prioritizing thermal conductivity and lightweight construction. The selection must balance thermal efficiency, durability, and cost-effectiveness.

Q3: How often should B-Tubes in folded radiators be inspected or replaced?

A3: Regular inspections should occur every 6-12 months, depending on operating conditions. Look for signs of corrosion, scaling, or wall thinning. Replacement is recommended when structural integrity is compromised or thermal performance decreases significantly. Proper maintenance extends tube lifespan and prevents unexpected system failures.

Q4: Can B-Tubes be customized for non-standard radiator designs?

A4: Yes, B-Tubes can be manufactured to meet custom lengths, diameters, and wall thicknesses to fit unique radiator configurations. Custom fabrication ensures optimal heat transfer performance while maintaining system integrity.

Q5: What are common installation challenges for B-Tubes?

A5: Challenges include ensuring proper alignment within folded radiator frames, avoiding tube deformation during installation, and sealing tube connections to prevent leaks. Professional installation and adherence to manufacturer guidelines are crucial for maintaining performance and safety.

5. Conclusion and Contact

B-Tubes are indispensable components for folded radiators, contributing to efficient heat transfer, system durability, and industrial reliability. Selecting the right B-Tube requires careful consideration of material, size, thermal properties, and maintenance schedules. By addressing these factors, industries can optimize radiator performance and extend operational lifespan.

Sinupower specializes in providing high-quality B-Tubes for folded radiators, offering custom solutions tailored to industrial needs. For inquiries, product specifications, or technical support, contact us directly and ensure your radiator systems operate at peak efficiency.