How to Choose the Right Attachment Plate for Industrial Machinery?

2025-12-23

Abstract: This article provides a comprehensive guide on Attachment Plates, detailing specifications, usage, common FAQs, and best practices for selecting the appropriate attachment plate for various industrial machinery applications. The discussion is structured into four main sections to cover technical aspects, operational insights, maintenance considerations, and selection guidance.

1. Introduction and Specifications

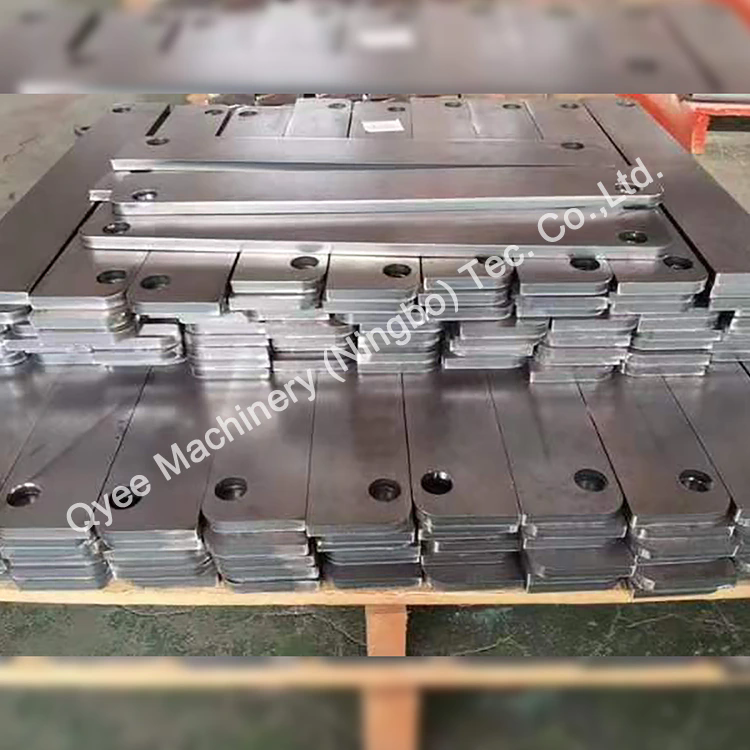

Attachment Plates are critical components used to connect various attachments to industrial machinery, including excavators, loaders, and other heavy equipment. The primary function of an attachment plate is to provide a secure and stable interface that ensures operational efficiency and safety. Selecting the correct attachment plate requires understanding its specifications, load capacity, and compatibility with machinery types.

Specifications of a Standard Attachment Plate

| Parameter | Details |

|---|---|

| Material | High-strength steel, heat-treated for durability |

| Dimensions | Standardized according to machine type, e.g., 500mm x 250mm x 25mm |

| Weight Capacity | Up to 5 tons depending on model |

| Surface Finish | Powder-coated or anti-rust treated |

| Attachment Types Compatible | Buckets, hydraulic breakers, grapples, and other implements |

Common Questions About Attachment Plate

Q1: How does an attachment plate improve machinery efficiency?

A: An attachment plate ensures a secure connection between machinery and attachments, reducing vibration, wear, and misalignment, which enhances operational efficiency and prolongs equipment life.

Q2: How to verify compatibility of an attachment plate with my machinery?

A: Compatibility is determined by the plate’s dimensions, weight capacity, and mounting type. Cross-referencing the machinery’s specifications with the plate’s datasheet ensures safe and efficient operation.

Q3: How frequently should an attachment plate be inspected?

A: Regular inspection is recommended every 100 operational hours or monthly, whichever comes first. Focus on wear, cracks, and bolt tightness to prevent accidents and maintain performance.

2. Operational Applications of Attachment Plates

Attachment plates are widely used across different industrial scenarios:

- Excavation: Connecting hydraulic breakers, buckets, and augers.

- Material Handling: Attaching grapples and lifting devices.

- Construction: Mounting specialized tools for concrete and demolition work.

- Forestry and Landscaping: Supporting mulchers, saws, and stump grinders.

Proper installation of the attachment plate enhances operational precision and safety. Using a certified plate prevents damage to the machinery and ensures compliance with industrial safety standards.

How to Choose the Right Attachment Plate for Specific Tasks?

Selecting the correct plate requires evaluating task type, weight load, and attachment interface. Standardized plates may suffice for general-purpose machinery, but high-performance operations may require customized plates with reinforced steel and precision drilling patterns.

3. Maintenance and Troubleshooting

Maintaining attachment plates involves routine checks, proper cleaning, and timely replacement of worn components.

How to Maintain Attachment Plates?

- Inspect for cracks, deformation, or surface corrosion monthly.

- Clean the mounting surfaces with appropriate solvents to prevent debris accumulation.

- Check bolt torque settings and replace any worn fasteners immediately.

- Lubricate contact points to reduce friction and wear.

Common Troubleshooting Scenarios

Problem: Attachment plate loosens during operation.

Solution: Recheck bolt torque, inspect plate for deformation, and verify compatibility with the attachment type.

Problem: Excessive vibration observed.

Solution: Ensure proper mounting alignment, inspect bushings, and replace worn plates if necessary.

4. Selection Guidance and QYEE Brand

Choosing the right attachment plate involves evaluating material strength, compatibility, load capacity, and manufacturer reliability. Trusted brands, like QYEE, offer high-quality attachment plates with standardized dimensions, rigorous testing, and durable finishes suitable for various industrial applications.

How to Select an Optimal Attachment Plate?

Selection criteria include:

- Material grade and tensile strength.

- Load-bearing capacity aligned with the intended operation.

- Surface treatment for environmental conditions (corrosion, abrasion resistance).

- Manufacturer reputation and warranty coverage.

How to Ensure Safe Operation with Attachment Plates?

Proper installation, periodic inspection, and adherence to load limits are critical. Employ certified operators and follow safety guidelines to prevent operational hazards.

For high-quality attachment plates and professional guidance, QYEE provides a range of solutions suitable for all industrial machinery requirements. Contact us today to discuss customized options and technical support.