How to Choose and Use Waterproof Aluminum Shell for Industrial Applications?

2026-01-05

Abstract: This comprehensive guide explores the applications, technical specifications, and practical considerations for selecting and using waterproof aluminum shells. It focuses on industry standards, durability factors, and answers common questions. By the end, readers will have a clear understanding of the benefits and correct utilization of waterproof aluminum shells in various industrial scenarios.

Table of Contents

Introduction to Waterproof Aluminum Shell

Waterproof aluminum shells are robust, corrosion-resistant enclosures designed to protect sensitive electronic devices, industrial machinery components, and outdoor equipment from moisture, dust, and other environmental hazards. These shells are widely used in industries ranging from manufacturing and energy to telecommunications and outdoor electronics. The primary goal of this guide is to provide an in-depth understanding of how waterproof aluminum shells can be selected, utilized, and maintained effectively, ensuring maximum protection and operational longevity.

Waterproof aluminum shells typically feature:

| Parameter | Specification |

|---|---|

| Material | High-grade aluminum alloy (6061-T6) |

| Surface Finish | Powder-coated or anodized for corrosion resistance |

| Protection Rating | IP65–IP68 waterproof standards |

| Operating Temperature | -40°C to 85°C |

| Weight | Varies from 1.2 kg to 15 kg depending on size |

| Size Options | Customizable according to equipment requirements |

Choosing the correct waterproof aluminum shell involves assessing environmental conditions, operational requirements, and compatibility with the devices it will protect. This guide aims to answer common industry questions, provide detailed technical insights, and outline practical use cases to help professionals make informed decisions.

Technical Specifications and Features

How to Assess the Waterproof Capability of an Aluminum Shell?

Waterproof aluminum shells are rated according to IP (Ingress Protection) standards, such as IP65, IP66, and IP68. The first digit indicates protection against solid particles (dust), while the second digit measures resistance to water ingress. Selecting the appropriate IP rating ensures devices are safeguarded against rain, splashes, and complete submersion if required.

How to Choose the Right Material and Finish?

High-grade aluminum alloys provide structural strength while remaining lightweight. Anodized or powder-coated finishes enhance corrosion resistance and extend the shell’s operational life. For outdoor or coastal applications, finishes with UV and salt spray protection are highly recommended to prevent premature wear.

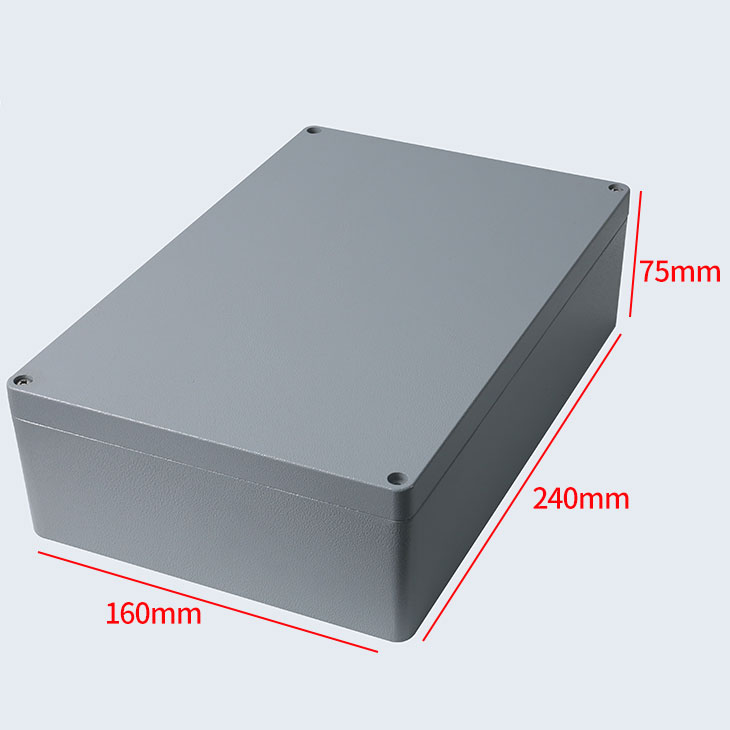

How to Determine Size and Fit for Equipment?

Accurate internal dimensions are critical to avoid mechanical stress on enclosed devices. Measure the width, height, and depth of the equipment, then consider additional space for cabling, heat dissipation, and ventilation. Modular or customizable shells offer flexibility for varied industrial setups.

Additional Features

- Integrated mounting brackets for wall or pole installations.

- Optional thermal insulation or internal padding.

- Lockable latches for enhanced security and tamper resistance.

Common FAQs on Waterproof Aluminum Shell

Q1: How durable are waterproof aluminum shells under extreme weather conditions?

A1: Waterproof aluminum shells made from high-grade alloys and anodized coatings can withstand extreme temperatures ranging from -40°C to 85°C, heavy rain, and strong UV exposure. They are designed to maintain structural integrity and protect internal components under long-term outdoor use.

Q2: How can waterproof aluminum shells be maintained to extend service life?

A2: Regular cleaning to remove dirt, salt deposits, and debris is recommended. Inspect seals and gaskets periodically to ensure no wear or gaps. Lubricate hinges and latches if applicable. For coastal or high-humidity environments, occasional re-application of protective coatings may further enhance durability.

Q3: How do waterproof aluminum shells compare to plastic or stainless steel enclosures?

A3: Compared to plastic, aluminum shells provide superior mechanical strength, better heat dissipation, and higher impact resistance. While stainless steel offers excellent corrosion resistance, aluminum is lighter, easier to customize, and often more cost-effective for large-scale industrial applications.

Applications and Industry Use Cases

How are waterproof aluminum shells applied in industrial electronics?

They protect sensitive electronics, such as control units, power converters, and communication equipment, from moisture and dust ingress. Enclosures are often deployed in outdoor substations, renewable energy installations, and factory floors where environmental exposure is high.

How are waterproof aluminum shells utilized in telecommunication systems?

Telecom operators use these shells to house networking devices, fiber optic junctions, and 5G equipment. By preventing water and dust intrusion, they ensure uninterrupted signal transmission and reduce the risk of costly downtime.

How are waterproof aluminum shells integrated into outdoor machinery?

Construction, agricultural, and marine machinery often incorporate aluminum shells for instrument panels and electronic modules. This prevents corrosion, ensures operator safety, and prolongs equipment lifespan under harsh conditions.

How are they customized for specialized applications?

Custom designs can include heat sinks, internal dividers, cable glands, and ventilation systems. Tailored dimensions, finishes, and mounting options allow engineers to meet precise operational requirements while maintaining waterproofing integrity.

Conclusion and Brand Information

Waterproof aluminum shells represent a critical solution for protecting industrial, electronic, and outdoor equipment from environmental hazards. By selecting the correct IP rating, material, size, and additional features, organizations can significantly enhance equipment reliability and service life. Among leading suppliers, Ruidafeng offers a wide range of waterproof aluminum shells designed for diverse industrial needs, combining quality, durability, and precision engineering. For inquiries, customization options, or bulk orders, please contact us to discuss your specific requirements and receive expert guidance.