How to Choose and Use Aluminum Extrusion Enclosures for Industrial Applications?

2025-12-26

Abstract: Aluminum Extrusion Enclosures are widely used in industrial and electronic fields for protecting sensitive equipment while ensuring efficient heat dissipation and structural integrity. This article explores in depth how to select, utilize, and maintain these enclosures, providing expert guidance, detailed product parameters, and practical insights for manufacturers and end-users.

Table of Contents

- Introduction to Aluminum Extrusion Enclosures

- Product Specifications and Parameters

- How to Properly Use Aluminum Extrusion Enclosures

- Common Questions About Aluminum Extrusion Enclosures

- Conclusion and Brand Information

1. Introduction to Aluminum Extrusion Enclosures

Aluminum Extrusion Enclosures are precision-engineered housings designed to provide protection for electrical, electronic, and industrial equipment. Constructed from high-quality aluminum alloys, these enclosures combine durability, corrosion resistance, and excellent thermal conductivity. They are suitable for applications in automation systems, power electronics, communication devices, and other industrial machinery.

The primary purpose of this article is to provide comprehensive insights on how to select the right Aluminum Extrusion Enclosure for specific applications, covering aspects such as size, wall thickness, surface finish, and accessory compatibility. By understanding these elements, manufacturers and engineers can optimize equipment performance, ensure long-term reliability, and achieve seamless integration with industrial systems.

2. Product Specifications and Parameters

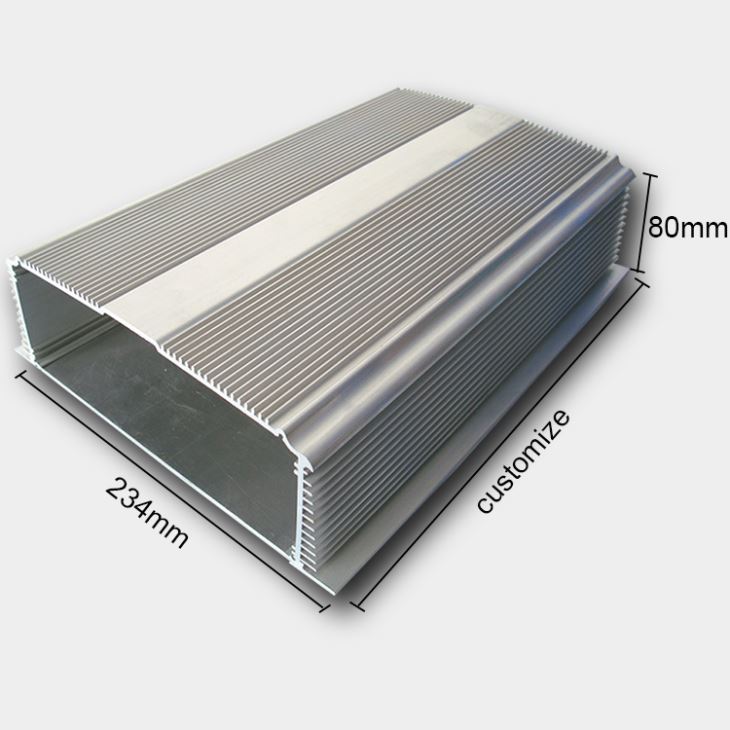

Understanding the technical specifications of Aluminum Extrusion Enclosures is critical to selecting the right product for any application. The following table summarizes the common parameters:

| Parameter | Typical Value / Range |

|---|---|

| Material | 6063-T5 Aluminum Alloy |

| Dimensions | Customizable: Length 50–1000mm, Width 50–400mm, Height 30–200mm |

| Wall Thickness | 1.5mm – 5mm |

| Surface Finish | Powder Coating, Anodized, Sandblasted |

| Color Options | Silver, Black, Customized |

| Ingress Protection | IP20 – IP65 (depending on sealing accessories) |

| Weight | 0.5 – 15 kg (depending on size and thickness) |

| Accessories | End Caps, Mounting Brackets, Cooling Fans, Gaskets |

3. How to Properly Use Aluminum Extrusion Enclosures

How to Select the Correct Size and Type?

Choosing the appropriate size and type requires analyzing the dimensions of internal components, required airflow for heat dissipation, and available mounting space. Engineers should consider maximum component height, power density, and cable routing requirements to prevent overcrowding and overheating.

How to Ensure Thermal Efficiency?

Thermal management is crucial for electronic devices. Aluminum Extrusion Enclosures naturally dissipate heat due to their high thermal conductivity. To enhance cooling, consider using enclosures with integrated heat sinks, ventilation slots, or attachable fans. Proper placement of components within the enclosure further optimizes airflow and prevents hot spots.

How to Maintain Durability and Corrosion Resistance?

Regular cleaning, avoiding exposure to corrosive chemicals, and using suitable sealing gaskets ensure long-term protection. Anodized or powder-coated surfaces add a layer of corrosion resistance, while proper installation prevents mechanical stress and deformation. Periodic inspection of mounting points and fasteners enhances structural reliability.

4. Common Questions About Aluminum Extrusion Enclosures

1. How to choose the best Aluminum Extrusion Enclosure for high-power electronics?

Select an enclosure with sufficient internal volume for components and airflow, prioritize aluminum alloys with excellent thermal conductivity, and ensure compatibility with heat sinks or active cooling systems. Proper sealing against dust and moisture is also recommended.

2. How to install Aluminum Extrusion Enclosures securely in industrial settings?

Use mounting brackets or custom fixtures, ensure flat and stable surfaces, and apply torque settings for screws according to manufacturer guidelines. Cable entry points should be sealed to maintain ingress protection ratings.

3. How to modify Aluminum Extrusion Enclosures for custom applications?

Machining or drilling for ports, connectors, or ventilation must follow precise measurements to avoid structural weakening. Consult with suppliers for pre-fabricated accessory options and use compatible gaskets or sealing solutions for modifications.

4. How to clean and maintain Aluminum Extrusion Enclosures?

Use non-abrasive cleaners, soft cloths, and avoid harsh chemical solvents. Periodically inspect for corrosion or surface scratches, and reapply protective coatings if necessary to maintain aesthetic and protective qualities.

5. Conclusion and Brand Information

Aluminum Extrusion Enclosures are essential for protecting industrial and electronic equipment, ensuring thermal management, and providing long-term structural integrity. By following careful selection, installation, and maintenance guidelines, users can optimize performance and reliability. Ruidafeng offers a wide range of Aluminum Extrusion Enclosures with customizable sizes, finishes, and accessories to meet diverse industrial needs. For personalized solutions and professional support, contact us today to discuss your specific requirements.