How Does Galvalume Coil Enhance Durability in Modern Construction?

2025-09-03

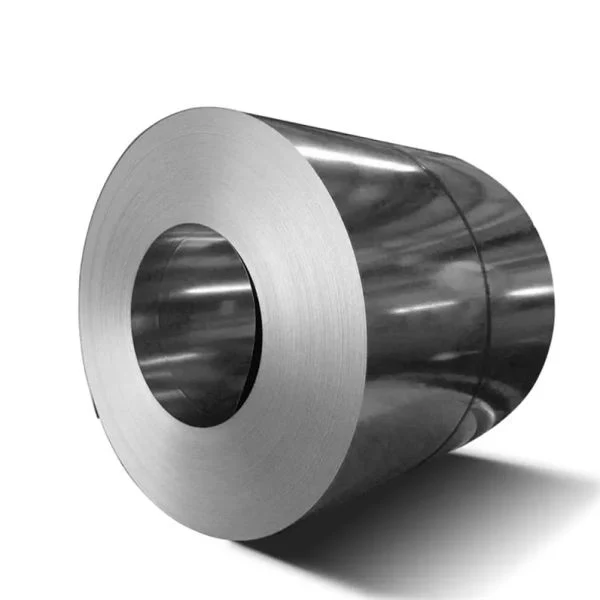

In today’s rapidly evolving construction and manufacturing sectors, the demand for materials that combine strength, durability, and cost-effectiveness has never been greater. Among these, Galvalume coil has emerged as one of the most sought-after solutions worldwide. Engineered with a precise blend of aluminum, zinc, and silicon, Galvalume steel coils are renowned for their exceptional corrosion resistance, heat reflectivity, and versatility across industries. From roofing systems and wall panels to household appliances and automotive parts, Galvalume coils deliver long-lasting performance and a sleek, modern appearance.

What Is Galvalume Coil and Why Is It Important?

Galvalume coil refers to a cold-rolled steel sheet coated with an alloy composed of approximately 55% aluminum, 43.4% zinc, and 1.6% silicon through a continuous hot-dip galvanizing process. This carefully engineered coating combines the protective properties of aluminum with the sacrificial protection of zinc, resulting in a steel material that resists corrosion up to four times better than traditional galvanized steel.

The unique composition ensures outstanding performance even in harsh environments, making Galvalume steel coils a preferred choice for:

-

Construction projects requiring weather-resistant roofing and siding materials.

-

Industrial applications where heat resistance and longevity are critical.

-

Automotive and appliance manufacturing where aesthetics meet durability.

Key Benefits of Galvalume Coil

-

Superior Corrosion Resistance – The aluminum-zinc coating protects steel against rust and oxidation, extending its lifespan significantly.

-

High Heat Reflectivity – Galvalume’s surface reflects heat effectively, reducing cooling costs in hot climates and enhancing energy efficiency.

-

Excellent Formability – Despite its strong coating, Galvalume can be easily shaped, bent, or roll-formed without compromising performance.

-

Cost-Effectiveness – Compared to stainless steel and other premium materials, Galvalume offers an ideal balance between quality and affordability.

-

Sustainability – Fully recyclable and energy-efficient, Galvalume contributes to eco-friendly construction practices.

Galvalume Coil Product Specifications

For engineers, manufacturers, and procurement managers, understanding the exact specifications of Galvalume coils is essential to ensure they meet project requirements. Below is a detailed specification table outlining the most common industry standards:

| Parameter | Specification |

|---|---|

| Base Material | Cold-Rolled Steel (CR) |

| Coating Composition | 55% Aluminum, 43.4% Zinc, 1.6% Silicon |

| Coating Weight | AZ50 – AZ200 (50–200 g/m²) |

| Thickness Range | 0.12 mm – 2.0 mm |

| Width Range | 600 mm – 1500 mm |

| Surface Finish | Regular Spangle / Zero Spangle |

| Tensile Strength | 270 – 550 MPa |

| Elongation | ≥ 12% |

| Surface Treatment | Chromated / Non-chromated / Oiled / Dry |

| Standard Compliance | ASTM A792 / JIS G3321 / EN 10346 |

| Packaging | Standard seaworthy export packing |

This flexibility in coating weights, thicknesses, and widths allows Galvalume coils to cater to a wide range of construction and manufacturing needs, from lightweight panels to heavy-duty industrial equipment.

Applications of Galvalume Coil Across Industries

Galvalume steel coils have a broad spectrum of uses, making them an ideal material for industries that demand high-performance, corrosion-resistant steel.

A. Building & Construction

One of the most significant applications is in the construction sector, where Galvalume coils are used for:

-

Roofing sheets and wall cladding

-

Gutters and downspouts

-

Fencing and structural framing

-

Pre-engineered building systems

Because Galvalume can withstand extreme weather conditions — from heavy rainfall to intense UV exposure — it has become a preferred choice for residential, commercial, and industrial buildings.

B. Automotive Industry

Galvalume’s lightweight yet strong properties make it suitable for manufacturing vehicle body panels, engine covers, and undercarriage components. Its resistance to road salt corrosion ensures longer-lasting performance in harsh winter environments.

C. Home Appliances

Manufacturers of washing machines, refrigerators, ovens, and air conditioners choose Galvalume steel coils due to their aesthetic finish and superior corrosion resistance.

D. Energy and Infrastructure

In renewable energy and infrastructure sectors, Galvalume steel is used for:

-

Solar panel mounting structures

-

Power transmission towers

-

Highway guardrails

Its ability to endure moisture, heat, and pollutants makes it indispensable for outdoor installations.

Frequently Asked Questions About Galvalume Coil

Q1: How does Galvalume coil compare to galvanized steel in terms of corrosion resistance?

A: Galvalume coil outperforms traditional galvanized steel by a significant margin. Thanks to its aluminum-zinc coating, Galvalume offers up to three to four times longer corrosion resistance in outdoor environments. While galvanized steel protects against rust through zinc coating alone, Galvalume’s aluminum component adds an additional barrier, making it highly effective even in coastal and humid regions.

Q2: Can Galvalume coil be painted or color-coated for aesthetic purposes?

A: Yes, Galvalume coil is highly compatible with various paint systems. Its smooth surface allows for excellent adhesion, making it ideal for color-coated roofing sheets, decorative panels, and branded products. When properly pre-treated, painted Galvalume maintains its durability while offering a wider range of design possibilities.

Choosing the Right Galvalume Coil Supplier

Selecting a reliable supplier is as important as choosing the material itself. Factors to consider include:

-

Quality Certifications – Ensure compliance with ASTM, JIS, and EN standards.

-

Consistent Material Properties – Uniform thickness, coating weight, and tensile strength.

-

Customizable Solutions – Options for size, finish, and packaging based on project needs.

-

Global Export Capability – A supplier experienced in international logistics ensures timely delivery and quality assurance.

When it comes to performance-driven Galvalume coils, Wanhetong has established itself as a trusted name in the industry. With state-of-the-art production facilities, strict quality control, and competitive pricing, Wanhetong delivers premium-grade Galvalume steel coils to clients worldwide.

Galvalume coil has become a game-changer in modern construction, manufacturing, and infrastructure development due to its superior corrosion resistance, versatility, and cost-effectiveness. Whether you are building high-performance roofing systems, producing durable appliances, or designing energy-efficient structures, Galvalume coils offer the reliability you need.

For engineers, architects, and business owners looking for premium Galvalume steel solutions, Wanhetong stands ready to deliver top-quality products tailored to your project’s specifications.

Contact us today to discuss your requirements, request a quote, or learn more about how our Galvalume coils can power your next project.