How Does an Aluminum Facade Transform Modern Architecture?

2025-09-30

In the last few decades, modern architecture has undergone a remarkable transformation, driven by innovation in construction materials and the rising need for sustainable, versatile, and aesthetically pleasing building solutions. Among the most impactful developments is the use of aluminum facades, a system that combines functionality with style while redefining the exterior of buildings worldwide.

The question at the center of today’s architectural progress is this: how does an aluminum facade transform a building’s performance and appearance while supporting environmental responsibility? To answer this, one must examine its design adaptability, structural durability, insulation performance, and long-term cost-effectiveness.

Aluminum facades are no longer limited to iconic skyscrapers or luxury complexes; they are now widely adopted in residential buildings, shopping malls, airports, cultural centers, and even healthcare facilities. Their popularity is rooted in how effectively they meet modern requirements—energy efficiency, lightweight design, weather resistance, and design flexibility.

Before diving deeper into how aluminum facades deliver these benefits, it is essential to highlight their fundamental product parameters, which form the backbone of their practical and aesthetic performance.

Product Parameters of Aluminum Facades

The performance of an aluminum facade is not only judged by appearance but also by technical specifications. These parameters determine how it behaves under environmental stress, integrates with structural frameworks, and sustains its visual appeal over decades.

Below is a structured overview of key product parameters that define high-quality aluminum facades:

| Parameter | Specification Range | Description |

|---|---|---|

| Material Composition | 100% Aluminum Alloy (e.g., 1100, 3003, 5005, 6061) | Provides strength, corrosion resistance, and flexibility for shaping. |

| Panel Thickness | 2mm – 6mm | Thicker panels enhance durability; thinner options reduce overall structure load. |

| Surface Finish | PVDF Coating, Powder Coating, Anodizing | Ensures UV resistance, color retention, and anti-corrosion properties. |

| Panel Size | Customizable (up to 1800mm × 6000mm) | Tailored for project-specific requirements, avoiding material wastage. |

| Weight | Approx. 5–8 kg/m² | Lightweight design reduces structural burden compared to stone or steel. |

| Fire Rating | Class A (Non-combustible under EN13501-1) | Meets global safety standards for fire resistance. |

| Insulation Compatibility | Rockwool, Glasswool, or PU Panels | Enhances thermal and acoustic performance when combined with insulation layers. |

| Installation Method | Cassette, Hook-on, or Unitized Curtain Wall | Adaptable systems depending on building type and design complexity. |

| Lifespan | 25–50 years (with minimal maintenance) | Proven durability with retained aesthetics. |

| Environmental Factor | 100% Recyclable | Aluminum can be recycled indefinitely without loss of quality. |

These parameters highlight not only the functional adaptability of aluminum facades but also their role in shaping modern architectural standards. They balance performance with sustainability while ensuring designers have complete creative freedom.

How Aluminum Facades Improve Building Performance

To truly understand how aluminum facades transform buildings, we need to analyze their impact across multiple dimensions: aesthetics, energy efficiency, structural safety, and long-term operational value.

Aesthetic Versatility

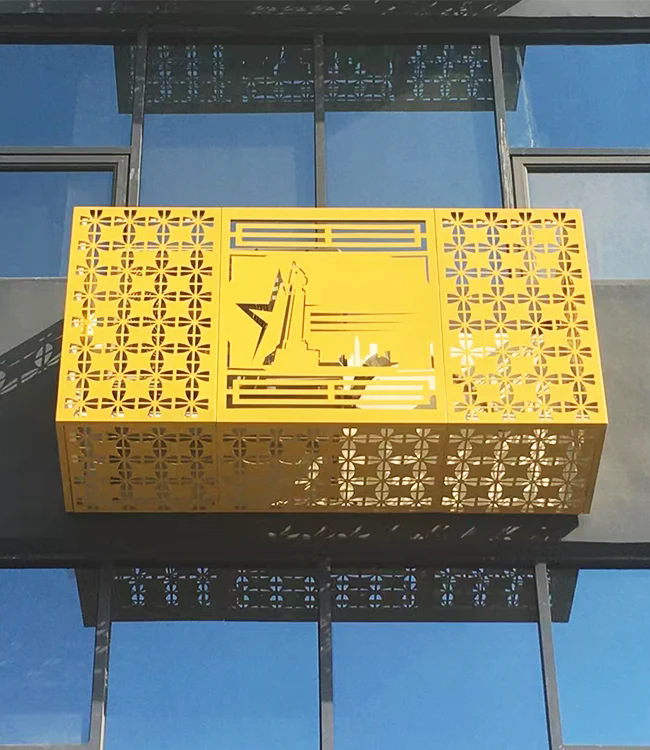

Aluminum facades enable architects to push creative boundaries. Unlike traditional stone or concrete finishes, aluminum panels can be cut, perforated, curved, or textured, creating endless possibilities for visual impact. From minimalist matte finishes to complex 3D shapes, facades add identity to buildings, making them stand out in urban skylines.

The range of color options offered by powder coating and PVDF treatments ensures buildings retain vibrancy even after years of sun exposure. This makes aluminum an ideal choice for institutions and commercial centers aiming to project modernity and prestige.

Energy Efficiency and Environmental Responsibility

One of the most pressing challenges in modern construction is reducing energy consumption. Aluminum facades address this through:

-

Thermal Insulation: When paired with rockwool or polyurethane insulation, facades minimize heat transfer, reducing dependence on HVAC systems.

-

Solar Control: Customized coatings and perforations regulate light penetration, keeping interiors cooler in summer while reducing glare.

-

Sustainability: Aluminum is infinitely recyclable, cutting down on environmental footprint. Recycling requires only 5% of the energy needed for primary production.

Thus, aluminum facades not only beautify buildings but also align with global environmental regulations and green building certifications such as LEED and BREEAM.

Structural Safety and Durability

Aluminum is naturally corrosion-resistant and performs exceptionally well in humid, coastal, or high-rainfall regions where steel and wood deteriorate faster. With appropriate surface coatings, aluminum panels resist scratches, UV damage, and air pollutants. Fire-rated facades further ensure occupant safety in compliance with international codes.

Additionally, the lightweight nature of aluminum significantly reduces structural load, offering more flexibility in high-rise construction.

Long-Term Economic Value

While the initial cost of aluminum facades may be higher than traditional cladding materials, the return on investment is superior. Their low maintenance requirements, long service life, and energy-saving potential result in reduced operational costs. In commercial real estate, buildings with modern facades command higher rental values and attract global investors, making aluminum facades a strategic choice beyond aesthetics.

Frequently Asked Questions (FAQ) about Aluminum Facades

Q1: How does an aluminum facade improve energy efficiency in buildings?

A1: Aluminum facades act as an insulating barrier that reduces heat transfer between outdoor and indoor environments. When paired with thermal insulation materials like rockwool or glasswool, they minimize reliance on air conditioning in summer and heating systems in winter. Additionally, coatings can reflect solar radiation, contributing to substantial energy savings across the building’s lifecycle.

Q2: How durable are aluminum facades compared to other cladding systems?

A2: Aluminum facades are designed to last between 25 and 50 years with minimal maintenance. Unlike wood, which is prone to rot, or steel, which is susceptible to rust, aluminum maintains structural integrity even in harsh weather conditions. Its non-combustible nature adds a layer of safety, while UV-resistant coatings preserve color and finish. Over decades, aluminum facades prove more cost-effective due to their durability and reduced maintenance costs.

Why Choose Aluminum Facades from Nante?

In exploring how aluminum facades shape the future of architecture, it becomes clear that they represent far more than an exterior finish. They embody the synergy of durability, sustainability, and creative freedom that modern construction demands. Their lightweight design reduces engineering challenges, their insulation properties support energy conservation, and their flexibility allows architects to design iconic, future-ready buildings.

For developers, contractors, and architects seeking to balance performance with elegance, aluminum facades stand as a strategic investment. Among global providers, Nante has established itself as a trusted name, delivering premium aluminum facade solutions tailored to project-specific requirements. With a commitment to innovation, quality control, and environmental responsibility, Nante ensures every facade system enhances both aesthetics and performance.

If you are planning a construction project that demands excellence in facade engineering, contact us today to discover how Nante can transform your architectural vision into reality.