How Does A TaC Coating Ring Extend The Lifespan Of Cutting And Forming Tools

2026-01-07

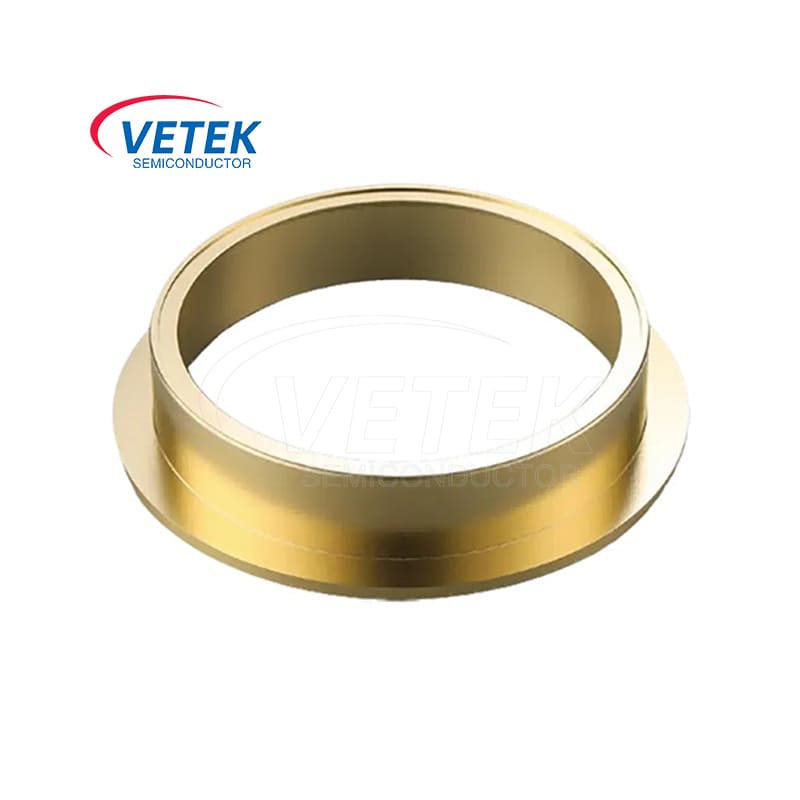

In the demanding world of precision machining and metal forming, tool failure is a constant cost driver. Uncoated tools succumb quickly to extreme heat, abrasive wear, and material adhesion. This is where advanced surface engineering makes a transformative difference. A TaC Coating Ring from VeTek represents a pinnacle of this technology, applying a microscopically thin yet incredibly resilient layer of Tantalum Carbide to dramatically enhance tool performance and longevity. But how exactly does this specialized coating achieve such remarkable results?

The core benefit of a VeTek TaC Coating Ring lies in its unique combination of material properties that directly combat the primary causes of tool degradation. Unlike standard coatings, Tantalum Carbide (TaC) forms an exceptionally hard and stable barrier on the tool's surface.

Here are the key mechanisms at work:

-

Unmatched Hardness & Abrasion Resistance: TaC is one of the hardest ceramic materials available.

-

Exceptional Thermal Stability: It maintains its integrity at temperatures exceeding 3000°C, preventing thermal softening.

-

Low Friction Coefficient: It reduces the cutting forces and heat generation during operation.

-

Chemical Inertness: It minimizes diffusion and adhesion between the tool and the workpiece material.

To understand the comparative advantage, consider this performance table:

| Tool Degradation Cause | Uncoated Tool Response | VeTek TaC Coating Ring Response |

|---|---|---|

| Abrasive Wear | Rapid edge rounding and material loss | Superior hardness dramatically slows wear rate |

| Thermal Fatigue | Cracking and softening due to heat cycles | Extreme thermal stability protects the substrate |

| Built-Up Edge | Workpiece material welds to the tool edge | Chemically inert surface prevents material adhesion |

| Oxidation | Scale formation weakens the tool at high heat | Forms a protective, oxide-resistant layer |

TaC Coating Ring FAQ Common Questions

What types of tools benefit most from a TaC Coating Ring?

Tools used for high-speed dry machining, forming of abrasive alloys (like titanium or Inconel), and precision operations where minimal tool deflection is critical see the most dramatic lifespan extensions, often by 300% or more.

How does the TaC coating process at VeTek ensure adhesion?

VeTek utilizes a controlled, high-temperature Physical Vapor Deposition (PVD) process in a precisely calibrated vacuum chamber. This ensures a metallurgical bond between the TaC Coating Ring layer and the tool substrate, preventing delamination under extreme stress.

Can a TaC Coating Ring be applied to any tool steel or carbide?

While highly versatile, optimal results require substrate compatibility. VeTek provides pre-coating consultation to evaluate your specific tool material and geometry, ensuring the coating process parameters are perfectly tailored for maximum adhesion and performance.

Investing in a TaC Coating Ring is not merely a purchase; it's a strategic upgrade to your manufacturing process. By shielding your most critical cutting and forming tools with this advanced technology, you directly reduce downtime, lower cost-per-part, and achieve more consistent, high-quality output. The extended tool life and improved performance delivered by a VeTek TaC Coating Ring provide a clear and rapid return on investment.

Ready to transform your tooling performance and productivity? Contact us today at VeTek to discuss a coating evaluation for your specific application.