How Does a Load Interrupter Switch Work in Medium Voltage Power Distribution Systems?

2025-12-30

Article Abstract

A Load Interrupter Switch (LIS) is a critical component in medium voltage power distribution networks, designed to safely interrupt load currents and provide visible isolation for electrical equipment. This article provides a comprehensive analysis of how a Load Interrupter Switch functions, its structural design, operating principles, and technical parameters. It also examines real-world applications, installation considerations, and future development trends driven by grid modernization.

Table of Contents

- 1. Product Overview and Core Operating Principles

- 2. Technical Parameters and Engineering Specifications

- 3. How Is a Load Interrupter Switch Applied in Real Power Systems?

- 4. Common Questions About Load Interrupter Switches

- 5. How Will Load Interrupter Switch Technology Evolve?

- 6. Conclusion and Industry Outlook

1. Product Overview and Core Operating Principles

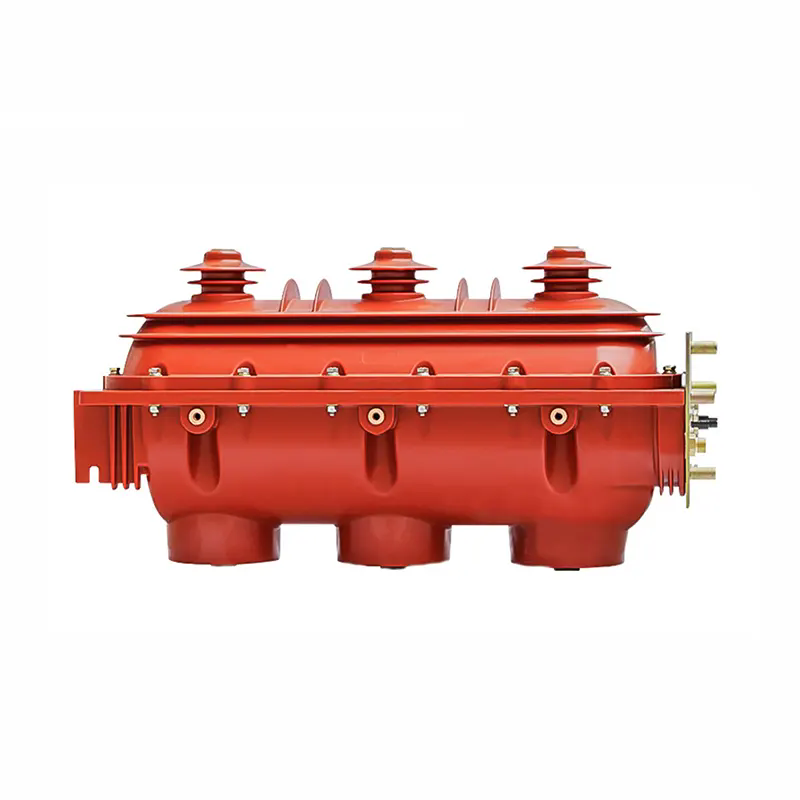

A Load Interrupter Switch is a mechanically operated switching device capable of making, carrying, and interrupting normal load current under specified medium voltage conditions. Unlike simple isolators, this switch is engineered with arc-quenching mechanisms that allow it to safely break load currents without causing damage to contacts or surrounding insulation.

The central purpose of a Load Interrupter Switch is to enable sectionalizing, isolation, and operational flexibility within power distribution networks. It is widely deployed in ring main units (RMUs), metal-enclosed switchgear, pad-mounted substations, and industrial power systems where controlled load switching is required.

The operating principle is based on rapid contact separation combined with arc extinction technologies such as air, SF₆ gas, or vacuum. When the switch is actuated, the moving contacts separate at a controlled speed, stretching and cooling the arc until it is extinguished at current zero. This ensures minimal contact erosion and reliable performance over repeated operations.

2. Technical Parameters and Engineering Specifications

Understanding the technical parameters of a Load Interrupter Switch is essential for correct system integration and long-term operational safety. These parameters define the electrical, mechanical, and environmental performance limits of the device.

| Parameter | Typical Range | Technical Explanation |

|---|---|---|

| Rated Voltage | 3.6 kV – 40.5 kV | Defines the maximum system voltage the switch can safely operate under continuous conditions. |

| Rated Current | 400 A – 1250 A | Indicates the continuous current-carrying capability without exceeding thermal limits. |

| Short-Time Withstand Current | 16 kA – 31.5 kA (1–3 s) | Represents the switch’s ability to endure fault currents for a defined duration. |

| Insulation Medium | Air / SF₆ / Vacuum | Determines arc-quenching performance and insulation reliability. |

| Mechanical Endurance | 5,000 – 10,000 operations | Reflects long-term durability under frequent switching conditions. |

From an engineering perspective, these parameters must align with system fault levels, protection schemes, and environmental conditions. Proper coordination ensures safe operation and compliance with IEC and ANSI standards.

3. How Is a Load Interrupter Switch Applied in Real Power Systems?

Load Interrupter Switches are deployed across a wide range of medium voltage applications. In utility distribution networks, they enable feeder sectionalizing, allowing utilities to isolate faults and restore service to unaffected areas rapidly.

In industrial facilities, the switch supports controlled power isolation for maintenance and operational safety. Its visible break feature provides clear confirmation of circuit isolation, which is critical for compliance with safety procedures.

Commercial infrastructure such as data centers, hospitals, and transportation hubs also relies on Load Interrupter Switches to enhance operational reliability. These environments require predictable switching behavior and minimal downtime, both of which are supported by robust LIS designs.

4. Common Questions About Load Interrupter Switches

Q: How does a Load Interrupter Switch differ from a circuit breaker?

A: A Load Interrupter Switch is designed to interrupt normal load current, whereas a circuit breaker can interrupt both load and high fault currents. Circuit breakers incorporate complex protection and tripping mechanisms, while Load Interrupter Switches focus on operational switching and isolation.

Q: Can a Load Interrupter Switch interrupt short-circuit current?

A: A Load Interrupter Switch cannot interrupt full short-circuit current. It is typically paired with upstream protection devices such as fuses or circuit breakers that clear fault conditions.

Q: What maintenance is required for a Load Interrupter Switch?

A: Maintenance generally includes visual inspection, contact wear assessment, insulation checks, and mechanical operation testing. The frequency depends on operating environment and switching cycles.

Q: Is remote operation possible for Load Interrupter Switches?

A: Yes. Many modern designs support motorized operation and SCADA integration, enabling remote monitoring and control within smart grid architectures.

5. How Will Load Interrupter Switch Technology Evolve?

The future development of Load Interrupter Switch technology is closely tied to grid digitalization and sustainability requirements. Increasing adoption of renewable energy sources places higher demands on switching reliability and operational flexibility.

Environmental considerations are driving innovation in insulation media, with alternatives to SF₆ gas gaining traction due to regulatory pressure. At the same time, digital sensors and condition monitoring systems are being integrated to provide real-time operational data.

These advancements position the Load Interrupter Switch as a foundational element in intelligent medium voltage networks, supporting predictive maintenance and improved system resilience.

6. Conclusion and Industry Outlook

A Load Interrupter Switch remains an indispensable component in medium voltage distribution systems, offering a balance of operational safety, reliability, and cost efficiency. Its role in enabling controlled load switching and visible isolation continues to support modern power infrastructure requirements.

Manufacturers such as DAYA electrical continue to refine Load Interrupter Switch designs to meet evolving grid standards and customer expectations. Through precise engineering, standardized manufacturing, and application-focused solutions, the industry is well-positioned to address future power distribution challenges.

For project-specific guidance, technical documentation, or customized solutions, interested parties are encouraged to contact us to discuss detailed requirements and application scenarios.