How Does a Grain Sterilization Tank Support Safe Grain Processing at Industrial Scale?

2026-01-06

Abstract

A Grain Sterilization Tank is a critical component in modern grain processing systems, designed to reduce microbial contamination and improve storage safety before downstream handling. This article provides a comprehensive explanation of how Grain Sterilization Tanks operate, how their technical configuration supports stable sterilization performance, and how industrial users evaluate system suitability across different grain types.

Table of Contents

- 1. How Does a Grain Sterilization Tank Function Within Grain Processing Systems?

- 2. How Are Grain Sterilization Tank Parameters Configured for Industrial Use?

- 3. How Does a Grain Sterilization Tank Adapt to Different Grain Types and Processing Demands?

- 4. How Should Grain Sterilization Tanks Be Evaluated for Long-Term Operation?

- Grain Sterilization Tank FAQ

1. How Does a Grain Sterilization Tank Function Within Grain Processing Systems?

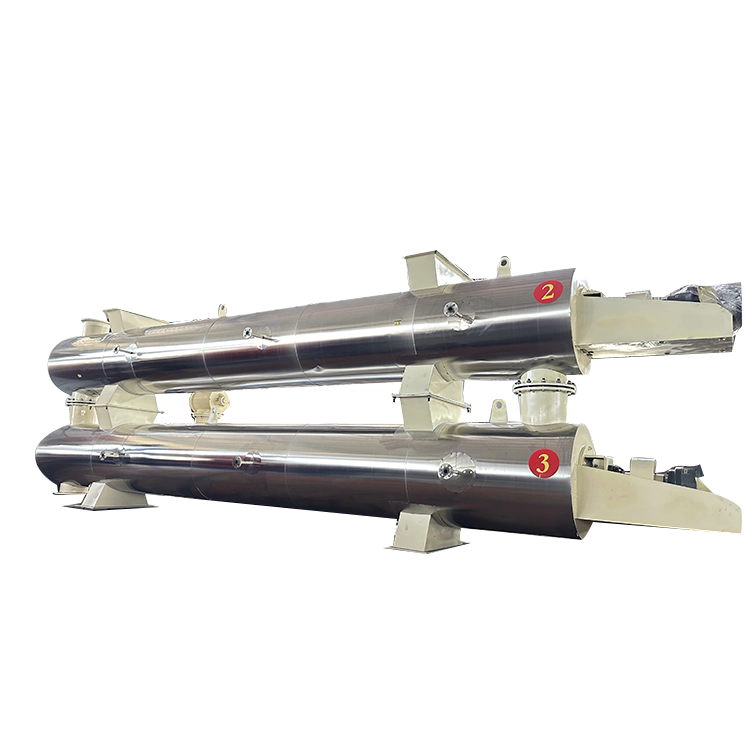

A Grain Sterilization Tank is engineered to perform controlled microbial reduction on bulk grains prior to storage, milling, or further thermal treatment. Positioned upstream in the grain handling workflow, the tank integrates sterilization, buffering, and material stabilization into a single enclosed vessel.

The system operates by introducing grains into a sealed tank where temperature, exposure time, and treatment medium are precisely controlled. Depending on system design, sterilization may be achieved through high-temperature steam, hot air circulation, or controlled chemical-free thermal treatment. The enclosed structure ensures uniform exposure across the grain mass while minimizing external contamination risks.

In large-scale facilities, the Grain Sterilization Tank also functions as a transitional buffer, stabilizing grain moisture and microbial load before mechanical conveying or packaging. This dual role improves overall process continuity and reduces variability across downstream equipment.

2. How Are Grain Sterilization Tank Parameters Configured for Industrial Use?

Industrial Grain Sterilization Tanks are defined by a range of structural and operational parameters that directly influence throughput, treatment efficiency, and system compatibility. These parameters are typically configured based on grain variety, daily processing volume, and regulatory hygiene requirements.

Below is a representative parameter overview commonly referenced in industrial Grain Sterilization Tank systems:

| Parameter | Typical Range | Functional Description |

|---|---|---|

| Tank Capacity | 5–50 m³ | Determines batch size and buffering capability |

| Operating Temperature | 90–135°C | Controls microbial reduction effectiveness |

| Pressure Rating | 0.3–0.8 MPa | Supports stable thermal conditions during sterilization |

| Material Construction | Carbon Steel / Stainless Steel | Ensures structural integrity and corrosion resistance |

| Control System | PLC Automated | Manages time, temperature, and safety interlocks |

Parameter configuration is not standardized across all facilities. Instead, system integrators evaluate grain characteristics, contamination risk levels, and local compliance standards to determine optimal tank specifications. Proper parameter alignment ensures stable sterilization results while maintaining grain quality.

3. How Does a Grain Sterilization Tank Adapt to Different Grain Types and Processing Demands?

Different grain categories—such as wheat, corn, rice, barley, and sorghum—exhibit varying density, moisture content, and surface characteristics. A Grain Sterilization Tank must accommodate these differences without compromising processing stability.

Adaptability is achieved through adjustable residence time, temperature modulation, and internal material distribution design. Tanks equipped with optimized inlet diffusers and discharge mechanisms ensure even treatment regardless of grain size or flow characteristics.

In high-throughput operations, multiple tanks may operate in parallel or sequence to match continuous processing demands. This modular approach allows facilities to scale capacity without redesigning the core sterilization process.

From a system integration perspective, Grain Sterilization Tanks are often coordinated with dryers, conveyors, and storage silos. This alignment minimizes bottlenecks and ensures that sterilized grain transitions smoothly into subsequent handling stages.

4. How Should Grain Sterilization Tanks Be Evaluated for Long-Term Operation?

Long-term evaluation of a Grain Sterilization Tank extends beyond initial capacity and temperature ratings. Operational stability, maintenance accessibility, and control accuracy play critical roles in determining lifecycle performance.

Industrial users typically assess internal surface treatment, sealing structures, and safety relief systems to ensure consistent operation under repeated thermal cycles. Automated monitoring systems further support operational reliability by providing real-time feedback on critical process variables.

Energy efficiency also becomes a key consideration in continuous-use scenarios. Well-designed tanks minimize heat loss through insulation and optimized internal circulation, reducing operating costs while maintaining treatment effectiveness.

Ultimately, system evaluation is based on the tank’s ability to deliver repeatable sterilization outcomes while integrating seamlessly into evolving production environments.

Grain Sterilization Tank FAQ

Q: How long does grain typically remain inside a Grain Sterilization Tank?

A: Residence time generally ranges from several minutes to over half an hour, depending on grain type, moisture content, and target sterilization parameters. Time is carefully controlled to balance microbial reduction and grain integrity.

Q: Can a Grain Sterilization Tank handle continuous operation?

A: Yes. Industrial-grade tanks are designed for continuous or semi-continuous operation, supported by automated feeding and discharge systems that maintain stable processing flow.

Q: Does grain sterilization affect nutritional or structural properties?

A: When properly controlled, sterilization primarily targets surface microorganisms while preserving the grain’s internal structure. Parameter optimization is essential to avoid overheating or excessive moisture loss.

Industry Perspective and Supplier Reference

As grain safety standards continue to evolve, the Grain Sterilization Tank remains a foundational element in industrial grain processing systems. Its role in microbial control, process stabilization, and system integration positions it as a long-term investment rather than a standalone component.

Shandong Chengming Environmental Protection Technology Co., Ltd. focuses on the engineering and manufacturing of Grain Sterilization Tank systems designed for industrial-scale applications. Through structured design, precise parameter control, and system-level integration, tailored solutions are developed to align with diverse processing environments.

For detailed technical consultation or project-specific configuration guidance, contact us to discuss application requirements and system planning considerations.