How Do Stamping Terminals Improve Electrical Connectivity?

2025-09-30

Electrical and electronic systems rely heavily on secure, reliable, and efficient connections. From automotive wiring harnesses to home appliances, the small components that form the backbone of connectivity play a decisive role in performance and safety. Among these components, stamping terminals stand out as critical solutions designed to ensure consistent conductivity, easy assembly, and cost efficiency.

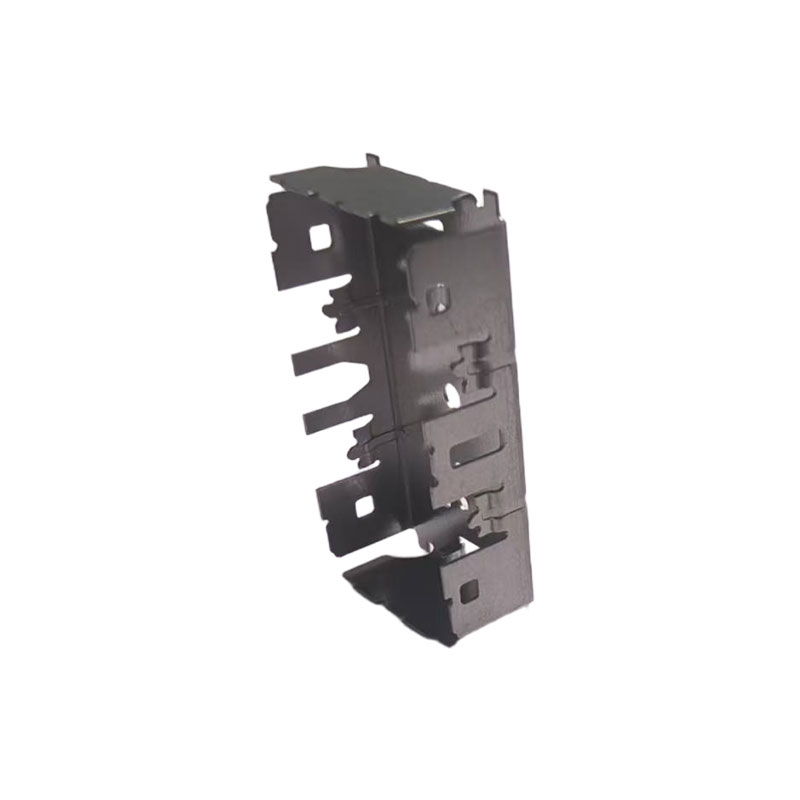

Stamping terminals are metallic components manufactured through precision stamping processes, where flat sheets of conductive metals such as copper, brass, or phosphor bronze are cut and formed into precise shapes. These terminals act as connectors that allow wires to be crimped, soldered, or inserted, creating a stable electrical path.

Their applications span across industries including:

-

Automotive (wiring harnesses, battery connections, sensors).

-

Consumer electronics (appliance wiring, circuit boards, connectors).

-

Industrial machinery (control panels, power distribution).

-

Telecommunications (signal connections, data transmission).

How Are Stamping Terminals Designed and Manufactured?

The Engineering Perspective

The manufacturing of stamping terminals requires a blend of material science, mechanical engineering, and electrical expertise. The process begins with metal selection, which is crucial for conductivity, strength, and resistance to corrosion. Metals commonly used include:

-

Copper: Superior conductivity, widely used for high-performance applications.

-

Brass: Balance of conductivity, mechanical strength, and corrosion resistance.

-

Phosphor Bronze: Excellent fatigue resistance, ideal for repetitive mechanical stress.

-

Nickel Alloys: Suitable for high-temperature or corrosive environments.

Once the material is selected, precision stamping presses and dies cut and shape the metal into highly accurate terminal geometries. Advanced stamping technologies allow for high-volume production without compromising tolerance standards.

Parameters and Specifications

To demonstrate the professional aspects of stamping terminals, below is a table outlining common specifications that engineers consider when selecting or designing them:

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Material | Conductive metals such as copper, brass, phosphor bronze, nickel alloys | Varies by application |

| Plating | Tin, nickel, silver, or gold for enhanced conductivity & corrosion resistance | 1–5 µm thickness |

| Terminal Type | Crimp, solder, press-fit, quick-disconnect, blade, ring, spade | Application-specific |

| Wire Size Compatibility | Range of wire gauges the terminal can accommodate | AWG 10–26 |

| Current Rating | Maximum electrical load without overheating | 5–50 Amps (application-based) |

| Operating Temperature | Safe thermal range for performance | –40°C to +150°C |

| Contact Resistance | Resistance at connection point | ≤ 5 mΩ |

| Durability (Cycles) | Number of insertion/withdrawal cycles without failure | 50–500+ cycles |

This professional data illustrates how every terminal is engineered for precise applications, ensuring long-lasting and reliable performance.

Quality Control

To maintain reliability, manufacturers implement strict quality checks such as:

-

Dimensional inspections with optical systems.

-

Electrical testing for resistance and conductivity.

-

Mechanical testing for crimping force, pull-out strength, and fatigue.

-

Surface plating inspections to verify corrosion resistance.

The combination of material expertise, advanced machinery, and rigorous testing ensures that stamping terminals meet the stringent requirements of modern industries.

How Do Stamping Terminals Enhance Efficiency and Reliability?

Key Advantages

Stamping terminals are more than simple connectors. They are engineered to deliver tangible benefits:

-

Improved Conductivity – By using high-quality conductive materials and specialized platings, terminals ensure minimal energy loss and stable current flow.

-

Mechanical Strength – Their design provides secure attachment between wire and connector, reducing risks of loose connections.

-

Ease of Assembly – Crimping, soldering, or press-fit techniques allow quick installation in mass production lines, saving labor time.

-

Cost Efficiency – High-volume stamping production lowers per-unit cost while ensuring consistency.

-

Durability – Properly designed terminals withstand vibration, mechanical stress, and environmental conditions such as humidity and temperature variation.

-

Safety Compliance – Designed to meet international standards such as UL, RoHS, and REACH, terminals ensure safe usage in regulated industries.

Application Scenarios

-

Automotive Wiring Harnesses: Stamping terminals provide secure and vibration-resistant connections essential for vehicle safety.

-

Consumer Electronics: In household appliances, they ensure safe power delivery while keeping manufacturing costs low.

-

Industrial Controls: Used in switchboards and power distribution units, they handle higher currents and maintain reliability under heavy-duty conditions.

-

Telecommunications: Their precision ensures signal integrity for high-speed data transmission.

Innovation in Design

With the rise of electric vehicles (EVs), renewable energy, and IoT devices, stamping terminals are evolving with:

-

Miniaturized designs for compact electronics.

-

High-current terminals for EV battery systems.

-

Eco-friendly plating solutions that reduce environmental impact.

-

Automated crimping compatibility for seamless integration with robotic assembly lines.

These innovations showcase how stamping terminals continue to adapt to the demands of modern technology, ensuring connectivity without compromise.

How Can Businesses Choose the Right Stamping Terminals?

Selection Guidelines

When choosing stamping terminals, engineers and procurement teams must carefully evaluate:

-

Electrical Requirements: Current load, voltage, and resistance.

-

Mechanical Requirements: Wire size, pull-out strength, and environmental conditions.

-

Application Type: Automotive, consumer electronics, industrial, or telecom.

-

Plating Material: Tin for general applications, nickel for durability, silver/gold for high-performance electronics.

-

Compliance Standards: UL certification, RoHS, and ISO standards.

The wrong choice can lead to system inefficiencies, overheating, or even safety hazards. Therefore, precision in selection ensures optimal performance.

Common FAQs

Q1: How do stamping terminals ensure reliable long-term performance?

A1: Stamping terminals use high-conductivity metals with protective plating, undergo strict quality inspections, and are designed to resist vibration, corrosion, and mechanical stress, ensuring reliability for years of operation.

Q2: How do I select the correct stamping terminal for my project?

A2: Start by assessing your wire gauge, current requirements, and environmental conditions. Then match these with terminal specifications such as plating type, crimping method, and compliance standards to ensure compatibility and safety.

Stamping terminals may appear small, but their impact on connectivity is massive. They are engineered to deliver durability, efficiency, and safety across multiple industries. Companies that prioritize quality in these components gain long-term advantages in performance and cost savings.

At Qiren, we specialize in providing high-quality stamping terminals manufactured under strict standards, ensuring that every product meets industry demands for precision and reliability. Whether you are in automotive, electronics, or industrial manufacturing, our solutions are tailored to your needs. To explore more about our stamping terminals or request a consultation, contact us and discover how Qiren can support your next project.