How Do Centreless Grinding Wheels Achieve Precision in Modern Manufacturing?

2025-12-22

Abstract: Centreless grinding wheels are critical components in high-precision machining and metal processing industries. This comprehensive guide covers their technical specifications, operational principles, common applications, and answers frequently asked questions. The content is structured to provide industry professionals with a clear understanding of these tools, ensuring optimal performance and informed purchasing decisions.

Table of Contents

1. Overview and Technical Specifications of Centreless Grinding Wheels 2. Operational Principles and Applications 3. Common Questions About Centreless Grinding Wheels 4. Industry Insights and Brand Reference1. Overview and Technical Specifications of Centreless Grinding Wheels

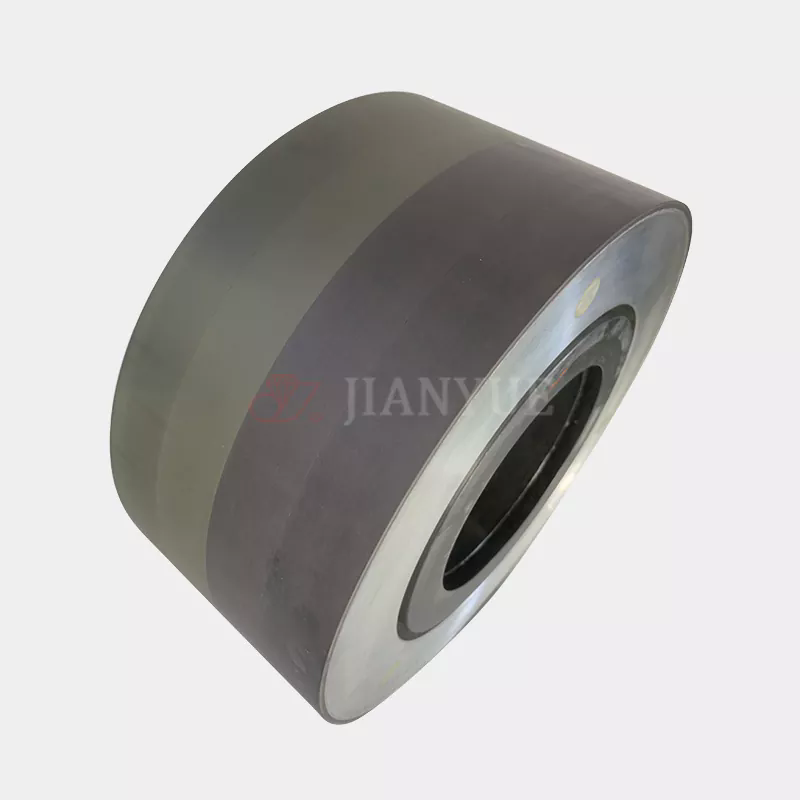

Centreless grinding wheels are specialized abrasive tools designed to perform high-precision grinding without the need for a central spindle. They enable continuous production of cylindrical components with tight tolerances, offering superior surface finish and dimensional accuracy. These grinding wheels are widely used in automotive, aerospace, tool manufacturing, and bearing production industries.

Core technical parameters of centreless grinding wheels include:

| Parameter | Specification |

|---|---|

| Wheel Diameter | 150 mm - 600 mm |

| Wheel Width | 25 mm - 100 mm |

| Grit Size | 60# - 1200# |

| Bond Type | Vitrified, Resin, Metal Bond |

| Hardness | H - Z (varies by application) |

| Max Peripheral Speed | 50 m/s |

| Application | Precision cylindrical grinding, high-speed production lines |

This data highlights the versatility and range of specifications available for different industrial needs, ensuring the selection of a grinding wheel matches operational requirements.

2. Operational Principles and Applications

Centreless grinding differs from traditional grinding methods because it does not require a spindle or fixture to hold the workpiece. Instead, the workpiece is supported between a grinding wheel and a regulating wheel, rotating and moving simultaneously. The unique setup allows for:

- High-speed and continuous operation suitable for mass production.

- Precision grinding of small to medium cylindrical components without the risk of eccentricity.

- Reduction of manual handling and setup time, enhancing efficiency.

Common industrial applications include:

- Automotive: crankshafts, camshafts, and gear shafts.

- Aerospace: precision turbine rods and hydraulic components.

- Bearing production: rolling element cylinders with tight tolerance requirements.

- Tool manufacturing: drills, pins, and mandrels requiring consistent diameters.

Manufacturers often integrate advanced monitoring systems with centreless grinding operations to optimize wheel wear, surface finish, and dimensional stability. Choosing the correct grit size, hardness, and bond type is essential to ensure longevity and reduce operational costs.

3. Common Questions About Centreless Grinding Wheels

Q1: How to select the correct grit size for a specific application?

A1: The selection of grit size depends on the material hardness, required surface finish, and production speed. Coarse grits (60# - 120#) are suitable for heavy stock removal, while fine grits (400# - 1200#) achieve high-precision finishes. Material compatibility should also be considered, as softer metals require finer abrasive particles to prevent glazing.

Q2: How often should centreless grinding wheels be dressed?

A2: Dressing frequency depends on wheel wear, material removal rate, and the desired surface finish. Typically, wheels are dressed when noticeable deterioration of roundness or finish occurs. For continuous production, automated dressing systems are recommended to maintain consistent performance without production downtime.

Q3: How to minimize vibration and achieve stable grinding?

A3: Minimizing vibration requires proper wheel balancing, machine alignment, and selecting the appropriate wheel hardness. Ensuring that the regulating wheel and work rest blade are correctly positioned reduces chatter. Additionally, maintaining consistent coolant flow and using high-quality abrasives can significantly improve grinding stability.

Q4: How to extend the life of centreless grinding wheels?

A4: Extending wheel life involves choosing the correct abrasive and bond, using proper dressing techniques, controlling grinding parameters, and implementing routine maintenance of machine components. Avoiding excessive feed rates and overheating ensures longer wheel durability and consistent product quality.

4. Industry Insights and Brand Reference

Centreless grinding technology continues to evolve, integrating advanced automation, real-time monitoring, and high-performance abrasives. Manufacturers now focus on precision, repeatability, and cost-efficiency to meet increasing industrial demands. Understanding the correct specifications, operational methods, and maintenance practices ensures that production lines operate at maximum efficiency.

JIANYUE provides high-quality centreless grinding wheels with extensive technical support, ensuring that customers achieve optimal precision and productivity. For inquiries or to explore product options, please contact us.