How Can Oxygen Free Copper Strip Enhance Electrical Reliability and Manufacturing Precision?

2025-07-14

Why is oxygen free copper strip preferred in high-end electronics?

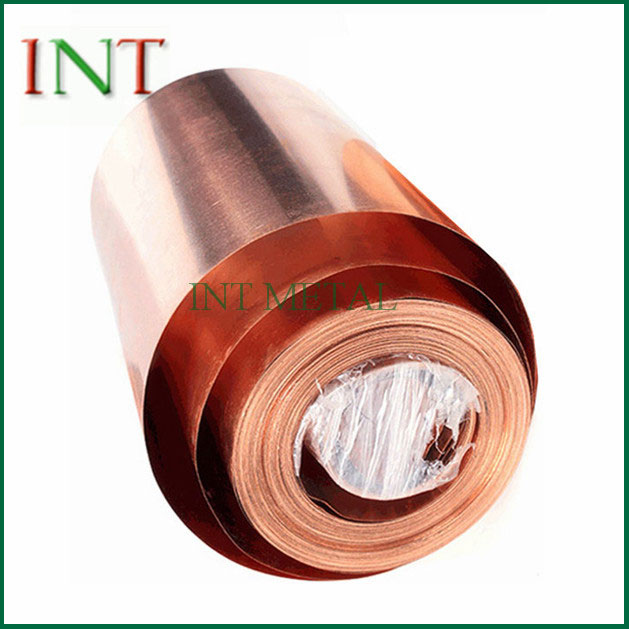

As someone involved in PCB and connector manufacturing, I can tell you that oxygen free copper strip has become essential for high-performance electrical systems. Its superior conductivity, ductility, and oxidation resistance make it ideal for fine stamping, micro-connections, and EMI shielding components.

What role does oxygen free copper strip play in power distribution systems?

Whether it's busbars in power stations or flexible connectors in electric vehicles, oxygen free copper strip ensures consistent conductivity with minimal energy loss. I’ve used INT copper strips in both low- and high-voltage assemblies, and their ability to maintain form and function under high current loads is impressive.

Why is INT a preferred supplier for oxygen free copper strip?

INT isn’t just a supplier—they’re a partner in quality. Their oxygen free copper strip goes through rigorous metallurgical testing, including grain size control and surface flatness. The result? A material that rolls smoothly, bonds effectively, and resists fatigue during mechanical forming.

Can oxygen free copper strip support modern energy technologies?

Definitely. With the rise of EVs, solar inverters, and energy storage systems, materials like oxygen free copper strip are more important than ever. INT’s solutions meet the demands of thermal cycling, high amperage flow, and precise die-cutting. We’ve integrated INT copper strips in several smart grid projects with excellent results.

How do I choose the right oxygen free copper strip for my application?

You’ll need to consider thickness, temper grade, and surface treatment. INT provides flexible customization, including rolled hard, annealed, or tin-plated options. Their oxygen free copper strip offerings are ideal for everything from high-frequency connectors to electromagnetic shields.

Ready to upgrade your copper components for optimal performance?

Choose INT oxygen free copper strip for unmatched conductivity, stability, and ease of fabrication. It’s the material engineers trust for mission-critical performance.

Our products are highly reliable. If you have any cooperation or bulk purchase needs, please contact us. We offer 24-hour online quality service.