Does Pure Copper Tarnish and How to Clean It Properly

2025-12-17

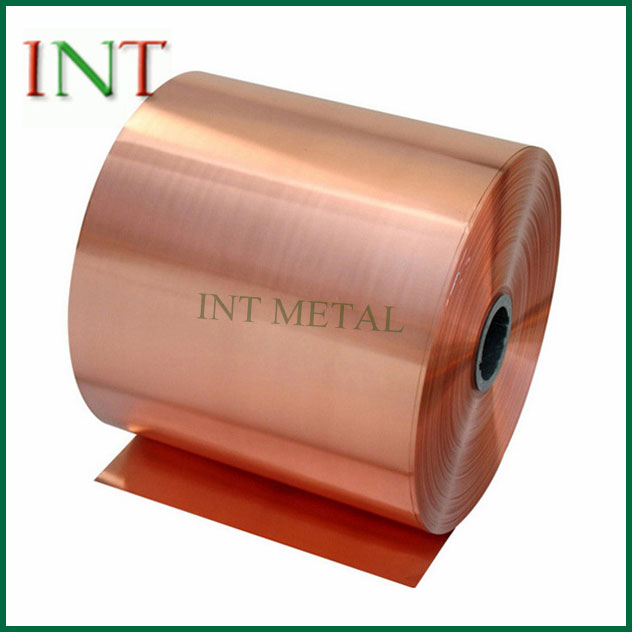

For centuries, pure copper has been prized for its excellent conductivity, beauty, and durability. At INT METAL, we specialize in providing premium pure copper materials for industrial, architectural, and specialized applications. A common question we encounter is about its maintenance. Yes, pure copper does tarnish. When exposed to air and moisture, it undergoes a natural oxidation process, forming a patina that can range from a darker brown to the iconic green hue seen on old roofs and statues. While some appreciate this aged look, many applications require keeping copper bright and shiny. Understanding this process is key to maintaining the performance and aesthetics of your INT METAL copper products.

Why Our INT METAL Pure Copper Stands Out

Our commitment at INT METAL is to deliver material excellence. Our pure copper is not just generic; it is sourced and processed to meet stringent specifications ideal for demanding environments.

-

High Purity Grade: We supply C10100 / C11000 electrolytic tough pitch (ETP) copper, guaranteeing a minimum of 99.99% copper content for optimal electrical and thermal conductivity.

-

Superior Surface Finish: Our materials feature a clean, smooth surface that is more resistant to uneven tarnishing and easier to clean when maintenance is required.

-

Consistent Quality: Uniform grain structure and alloy consistency ensure predictable performance and longevity in your projects.

INT METAL Pure Copper - Key Product Parameters

| Parameter | Specification | Benefit |

|---|---|---|

| Copper Content | ≥ 99.99% | Ensures maximum electrical & thermal conductivity. |

| Density | 8.96 g/cm³ | Confirms material authenticity and purity. |

| Thermal Conductivity | 401 W/m·K | Excellent for heat exchanger and cookware applications. |

| Tensile Strength | 220-280 MPa | Provides a good balance of formability and strength. |

| Typical Forms | Sheet, Plate, Tube, Bar, Wire | Versatility for diverse industrial and design needs. |

How to Clean Tarnished Pure Copper Properly

For light tarnish, a homemade solution often works well. Mix equal parts vinegar and salt or lemon juice and salt. Gently rub the paste onto the pure copper surface with a soft cloth, rinse thoroughly with water, and dry immediately. For heavier tarnish or for maintaining the pristine condition of INT METAL materials in critical applications, we recommend using a specialized, non-abrasive copper polish. Always test any method on a small area first. Important: After any cleaning, ensure the product is completely dry to prevent water spots and immediate re-tarnishing.

Pure Copper FAQ

Q: Does the patina (tarnish) on pure copper damage the metal?

A: No, the patina is a protective layer that actually shields the underlying pure copper from further corrosion. In many architectural applications, this stable patina is desired for its look and protective qualities.

Q: Can I prevent my pure copper from tarnishing at all?

A: While you cannot stop the natural oxidation process completely, you can significantly slow it down. Applying a clear lacquer or wax coating designed for metals after polishing will create a barrier against air and moisture. For INT METAL products in functional applications, regular dry polishing with a microfiber cloth can maintain shine.

Q: Is tarnished pure copper less effective for electrical or thermal uses?

A: For thermal applications like cookware, a thick tarnish layer can slightly reduce efficiency. In critical electrical connections, tarnish (which is an oxide) is a poor conductor and must be cleaned to ensure optimal performance. Our high-grade INT METAL pure copper is ideal where consistent, long-term conductivity is paramount.

Maintaining your pure copper investments ensures they perform beautifully for years. For projects that demand the highest quality materials with reliable specifications, choosing INT METAL is the definitive solution.

Ready to specify the finest pure copper for your next project? Contact our technical sales team at INT METAL today for a quote and expert material consultation.