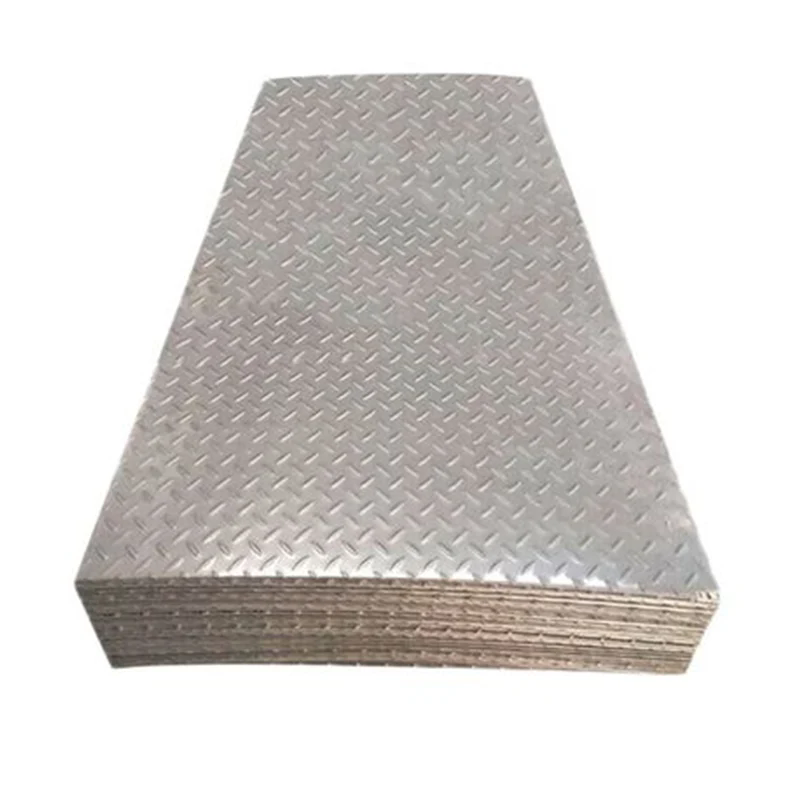

Carbon steel plate: basic material in the field of industry and construction

2025-07-25

In industrial production and construction, carbon steel plate has become a widely used basic material due to its mechanical properties and material adaptability. It achieves a balance between strength and toughness by adjusting the carbon content, which can not only meet the functional requirements of load-bearing and wear resistance, but also has an irreplaceable position in many fields due to its convenient processing and reasonable cost.

The intrinsic relationship between composition and performance

The core performance of carbon steel plate is closely related to its carbon content. Low-carbon steel plate has a low carbon content, good plasticity and weldability, and is easy to process into various complex shapes, suitable for manufacturing parts that require bending and stamping; medium-carbon steel plate achieves a good balance between strength and toughness, and is often used for structural parts that require a certain load-bearing capacity; high-carbon steel plate has high hardness and strong wear resistance, and is suitable for making products such as knives and molds that require high wear resistance. This performance difference due to different compositions allows carbon steel plates to accurately match the use requirements of different scenarios.

Processing characteristics and application advantages

The convenience of processing carbon steel plates is an important reason for their wide application. Whether it is cutting, welding or forging, it can be completed efficiently through conventional processes, and the material performance is stable during the processing, and it is not easy to have problems such as cracks and deformation, which can ensure the accuracy and quality of the finished product. At the same time, its wide source and mature production process make the material cost relatively controllable, which can effectively control the overall cost in large-scale industrial production and provide enterprises with cost-effective material options.

Functional adaptation in different scenarios

In the field of construction, carbon steel plates can be used to manufacture steel structure frames. With its high strength, it supports the overall weight of the building and resists external forces such as wind and earthquakes; in mechanical manufacturing, it is a common material for various mechanical parts and can withstand friction and impact during mechanical operation; in the automotive industry, some load-bearing parts also rely on the mechanical properties of carbon steel plates to ensure the structural safety of vehicles during driving. This characteristic of stable function in different scenarios makes it a basic supporting material in the industrial system.

Development trend of performance optimization

With the advancement of technology, the performance of carbon steel plates is still being optimized. Through advanced rolling technology and heat treatment technology, its strength, corrosion resistance and other properties can be further improved, and the scope of application can be expanded. For example, surface-treated carbon steel plates can reduce rust in humid environments, extend service life, and meet the use requirements of more special environments.

Wanhetong Steel (shandong) Co., Ltd. demonstrates professional strength. The company focuses on the quality control of carbon steel plates, and strictly manages the entire process from raw material selection to production and processing to ensure the stability of the product in terms of mechanical properties and processing performance, providing reliable material support for the fields of construction, machinery, and automobiles, helping various industries find the best balance between cost and performance and promoting efficient industrial development.