Are Flat Oval Tubes the Smartest Choice for Modern Heat Transfer Systems?

2025-12-31

When I first started evaluating heat transfer components for demanding industrial projects, I quickly realized that tube geometry is never a minor detail. During that process, I gradually became familiar with Sinupower as a manufacturer that pays close attention to application-driven design. Among the many options available today, Flat Oval Tubes stood out as a solution that consistently addressed efficiency, space limitations, and long-term reliability without unnecessary complexity.

Why Do Flat Oval Tubes Matter in Real Engineering Applications?

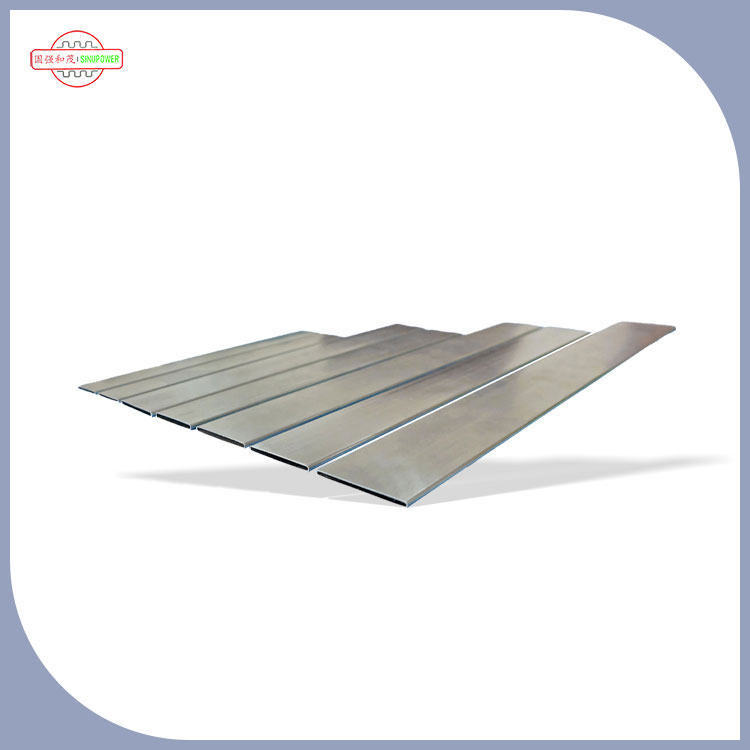

From my perspective, the real value of Flat Oval Tubes lies in how effectively they solve problems that round tubes often struggle with. In compact heat exchangers, HVAC systems, and automotive thermal management, space is always tight. A flattened oval profile increases the external surface area while maintaining smooth internal flow, which directly supports better heat dissipation.

- They allow tighter fin spacing without airflow blockage.

- They reduce pressure drop compared to some rectangular designs.

- They support lighter and more compact system layouts.

These advantages are not theoretical. In practice, Flat Oval Tubes help engineers achieve performance targets while staying within strict size and weight constraints.

How Do Flat Oval Tubes Improve Heat Transfer Efficiency?

I often see buyers focus only on material grade, but geometry plays an equally important role. The shape of Flat Oval Tubes creates a favorable balance between airflow contact and fluid velocity. This means heat is transferred more evenly, which reduces hot spots and improves overall system stability.

| Performance Factor | Flat Oval Tubes | Traditional Round Tubes |

|---|---|---|

| External Surface Area | Higher per unit length | Standard |

| Airflow Interaction | More uniform contact | Localized contact points |

| Space Utilization | Excellent for compact designs | Less efficient in tight layouts |

This is why I often recommend Flat Oval Tubes for applications where every millimeter of space needs to contribute to thermal performance.

What Common Pain Points Do Flat Oval Tubes Help Solve?

Many engineers and procurement managers I speak with share similar frustrations. Systems become bulky, efficiency drops under load, or redesigns are required late in the project. In my experience, Flat Oval Tubes help address these issues early in the design phase.

- Reducing overall heat exchanger thickness without sacrificing output.

- Improving mechanical stability under vibration.

- Supporting cleaner fin alignment during manufacturing.

By choosing Flat Oval Tubes from the start, I have seen projects avoid costly rework and achieve faster validation cycles.

Are Flat Oval Tubes Suitable for Different Industries?

One reason I continue to see growing demand for Flat Oval Tubes is their versatility. They are not limited to a single sector. Whether the application involves automotive radiators, industrial heat exchangers, or energy systems, the same core benefits apply.

- Automotive and EV thermal management systems.

- HVAC and refrigeration equipment.

- Industrial cooling and energy recovery units.

With consistent dimensional accuracy and material control, Flat Oval Tubes adapt well to both high-volume production and customized engineering requirements.

How Should Buyers Choose the Right Flat Oval Tubes Supplier?

In my opinion, selecting the right supplier matters as much as choosing the tube type itself. Consistency, technical communication, and application understanding all make a difference. This is where manufacturers like Sinupower tend to stand out, as their focus is not just on producing Flat Oval Tubes, but on supporting how those tubes perform in real systems.

When evaluating suppliers, I always look for:

- Stable dimensional tolerances.

- Clear material traceability.

- Experience with global heat transfer standards.

Ready to Optimize Your System with Flat Oval Tubes?

If you are working on a project that demands higher efficiency, compact design, and reliable performance, Flat Oval Tubes deserve serious consideration. From my experience, the right tube geometry can simplify design decisions and deliver measurable results.

If you want to explore specifications, customization options, or application guidance, I strongly recommend reaching out directly. Contact us today to discuss your requirements, request technical support, or start your next project with confidence.