How to Select the Right Aluminum Coil for Industrial Applications?

2025-12-31

Summary: Aluminum coils are critical materials widely used in construction, automotive, electronics, and packaging industries due to their lightweight, corrosion resistance, and versatility. This article provides a comprehensive guide on Aluminum Coil selection, including specifications, practical applications, common questions, and expert recommendations for optimal industrial use.

Table of Contents

- Introduction to Aluminum Coil

- Detailed Specifications of Aluminum Coil

- Common FAQs About Aluminum Coil

- Industrial Applications and How to Choose

- Conclusion and Contact Information

1. Introduction to Aluminum Coil

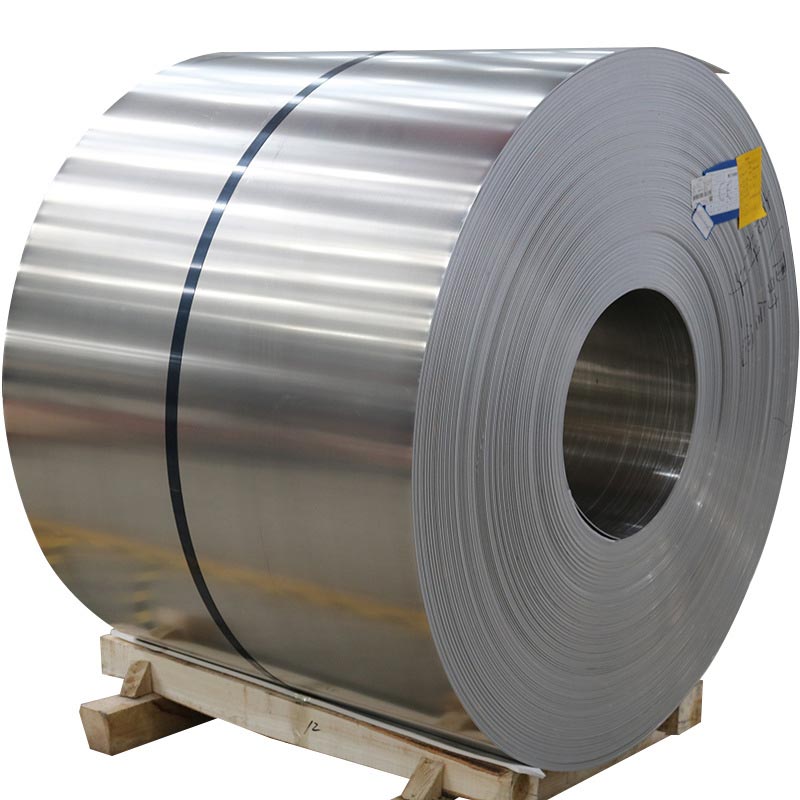

Aluminum Coil is a rolled product made from high-purity aluminum or aluminum alloy that is widely utilized in industrial and manufacturing sectors. These coils are produced through a cold-rolling or hot-rolling process and are designed to provide flexibility, durability, and precision in applications ranging from roofing and wall panels to automotive parts and heat exchangers.

The focus of this article is to answer critical questions on how to select the right Aluminum Coil for various industrial purposes. Proper selection ensures performance, efficiency, and longevity of the final product while optimizing costs.

2. Detailed Specifications of Aluminum Coil

The following table summarizes the key technical parameters of standard Aluminum Coil products:

| Parameter | Range / Value |

|---|---|

| Alloy Type | 1050, 1100, 3003, 3105, 5052, 5754, 6061 |

| Thickness | 0.2mm - 3.0mm |

| Width | 600mm - 2000mm |

| Coil Weight | 2MT - 8MT |

| Surface Finish | Mill Finish, PVDF Coated, Anodized, Painted |

| Tensile Strength | 70-310 MPa (depending on alloy and temper) |

| Temper | O, H14, H18, H24, H32 |

| Corrosion Resistance | High resistance to oxidation and environmental corrosion |

These parameters are essential for engineers and procurement specialists to determine which Aluminum Coil meets the operational and structural requirements of their projects.

3. Common FAQs About Aluminum Coil

How to ensure Aluminum Coil meets quality standards?

Quality assurance involves checking alloy composition, thickness uniformity, surface smoothness, and tensile strength. Compliance with ISO 9001 and ASTM standards is recommended for industrial applications.

What is the difference between hot-rolled and cold-rolled Aluminum Coil?

Hot-rolled coils are manufactured at high temperatures and are suitable for structural applications where dimensional precision is less critical. Cold-rolled coils are processed at room temperature, offering higher strength, smoother surfaces, and precise thickness for decorative or industrial uses.

How to store Aluminum Coil to prevent damage?

Aluminum Coils should be stored in dry, ventilated areas to prevent oxidation or corrosion. Avoid stacking coils directly on the floor; use wooden pallets or protective covers to minimize surface scratches and mechanical damage.

4. Industrial Applications and How to Choose

Selecting the appropriate Aluminum Coil requires understanding both application needs and material properties. Key considerations include alloy selection, surface finish, thickness, and environmental exposure.

How to choose Aluminum Coil for construction?

Construction projects often require corrosion-resistant and lightweight materials. Coils with PVDF coating or anodized finishes offer enhanced durability for exterior walls, roofing, and curtain walls.

How to select Aluminum Coil for automotive manufacturing?

Automotive applications demand high-strength, lightweight, and formable coils. Alloys like 5052 and 6061 in cold-rolled temper provide excellent rigidity, corrosion resistance, and paint adhesion for body panels and heat exchangers.

How to use Aluminum Coil in electronic devices?

Electronics require aluminum for heat dissipation and conductivity. Thin, cold-rolled 1100 or 3003 alloys with smooth finishes are ideal for casings, housings, and heat sinks.

How to choose Aluminum Coil for packaging and household products?

For packaging, lightweight and easily formable aluminum such as 1100 or 3003 alloy is preferred. Thickness should be selected based on rigidity requirements, and surface finishing should ensure aesthetics and corrosion resistance.

5. Conclusion and Contact Information

Proper selection of Aluminum Coil directly impacts project efficiency, durability, and overall cost-effectiveness. Industrial specialists must evaluate specifications, application requirements, and storage methods to maximize material performance. Wuxi Jianbanghaoda Steel Co., Ltd offers a wide range of high-quality Aluminum Coils suitable for various sectors including construction, automotive, electronics, and packaging.

For further details and customized solutions, contact us today to ensure the optimal Aluminum Coil is chosen for your next project.